NaN / 0

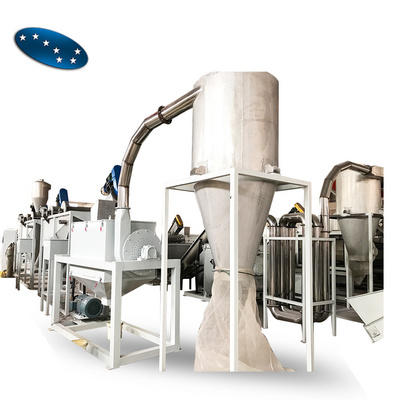

PE PP Film recycling and washing line pet bottle plastic recycling machine

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Machine Type:

PP PE Film Washing Line

Max.Production Capacity (kg/h):

1500

Place of Origin:

Hubei, China

Brand Name:

Ruili

Product Details

PE PP Film recycling and washing line pet bottle plastic recycling machine

Product Description

Plastic Recycling Machine Production Line Standard Process:

1) Plastic film recycling machine production line

Feeding conveyor → Crusher → Friction washer (use 1 set or 2 set depend on material)→ Washing tank → Vertical loader → Friction Washer → Washing tank → Centrifugual dewatering machine/Squeezing machine/Squeezing Primary Pelletizer

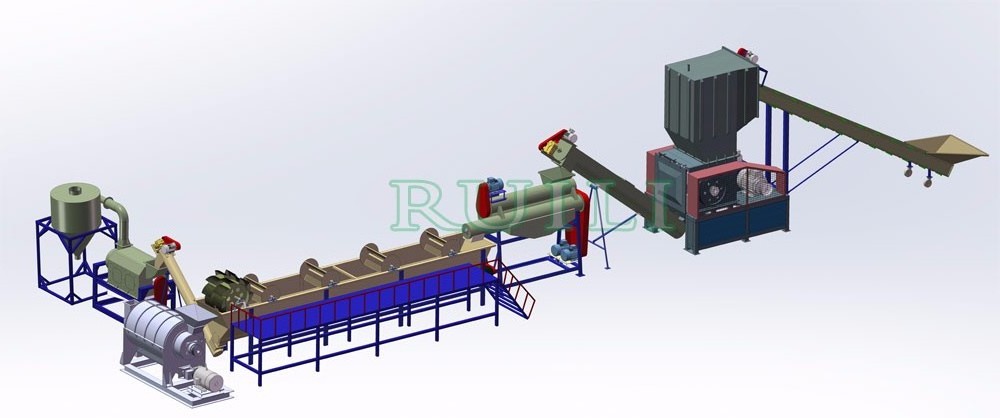

2) PET bottle recycling machine production line

Bale opene r → Feeding conveyor → Label remover → Sorting conveyor → Feeding conveyor → PET bottle crusher → Screw conveyor → Washing tank → Friction washer → Screw conveyor → Hot washer → Screw conveyor → Friction washer → Rinsing washing tank → Rinsing washing tank → Horizontal dewatering machine → Packaging

Plastic Recycling Machine Production Line Characters

1. Raw material: Plasti c film washing line is widely used to treat waste PP woven bags, PE Plastic film,plastic bags, plastic garbage, waste plastic mulch film,nylon film.

2. Production process: a crushing, washing, drying line.

3. This production line is high automatic operating and save labor cost and low after maintenance.

4. With advanced international industry concepts and technologies to meet waste plastic recycling.

5. This film recycling machine could be displayed "L" or "U" shape according clients' workshop.

We can design different plastic washing line according to your requirements:

a. Equipment name: plastic film recycling equipment.

b. Production capacity: 500kg/h,1000kg/h 1500kg/h,2000kg/h,3000kg/h.

c. Material processed: plastic film (such PP bags ,PE film etc )

d: We providing complete service for you. Design-Product-Installment-Testing.

e. Superiority: Easy operation, high capacity, low energy consumption, safety, reliability, etc.

Features & Technique:

a. We have the bale opening and feeding system which and equally feeding the material save labor.

c. Metal detector is optional for you which used to take out any kinds of metal from the plastic film.

d. Specially designed Film dewatering machine can make the best dehydration effect for film.

e. High speed dewatering machine and the drying system can guarantee the film flakes moisture <1%.

f. The final label separator machine will remove the final labels from the flakes to guarantee the PVC content.

Parameter of Plastic Washing line

|

Input Capacity |

500kg/h |

1000kg/h |

2000kg/h |

|

Workshop(M*M*M) |

35(L)*10(W)*6(H) |

45(L)*10(W)*6(H) |

55(L)*15(W)*6(H) |

|

Ancillary Staff |

4 Persons |

6 Persons |

8 Persons |

|

Installation Power |

156kw |

298kw |

386kw |

|

Water Consumption |

2 Ton/h |

3 Ton/h |

4 Ton/h |

|

Final Product |

Moisture:max1% Bulk density: 0.3G/CM3 Particle size: 1-12mm Metal content: max20ppm Floatable contamination: less than 200ppm Total impurity: 250ppm |

Moisture:max1% Bulk density: 0.3G/CM3 Particle size: 1-12mm Metal content: max20ppm Floatable contamination: less than 200ppm Total impurity: 250ppm |

Moisture:max1% Bulk density: 0.3G/CM3 Particle size: 1-12mm Metal content: max20ppm Floatable contamination: less than 200ppm Total impurity: 250ppm |

More pictures :

Our Services

Pre-sale: we given client the details technician offer, sign the sales contract etc.

In-sales: we supply the details layout, installation instruction, technician support for the clients.

After sales: we arrange engineer to install the machinery and training the workers for client. We always update the new technology to every customer.

Packaging & Shipping

After the contract comes into effect, buyer pay deposit, we will start to produce. When all the machines are completed, buyers come to factory to observe and test machine by themselves, until all the machines are satisfied with the buyers, they can pay for the other balance. Our company arrange to shipping goods to buyer. We provide the goods to be shipped by air or by sea. Pictures of cargo loading will be sent to every client to check and keep recording.

Package :

Packing with film, pallet or wooden case.(according to customers' request).