NaN / 0

plastic bottle recycling machine pet / plastic bottle washing line

Get Latest Price

US$ 65000

≥1 Sets

US$ 62000

≥2 Sets

Quick Details

Machine Type:

PET Bottle Washing Line

Max.Production Capacity (kg/h):

2000

Place of Origin:

Jiangsu, China

Brand Name:

Sevenstars

Product Details

plastic bottle recycling machine pet / plastic bottle washing line

Basic information:

Capacity: 300-3000kg/h

Material: Stainless steel 304

Electrical parts: ABB, SIEMENS,schneider

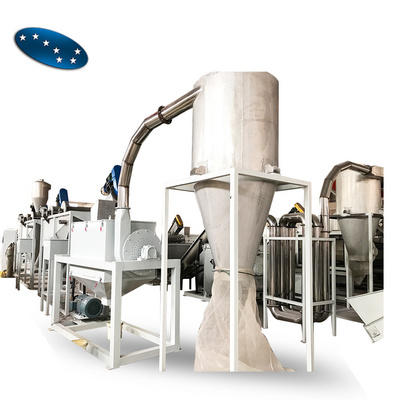

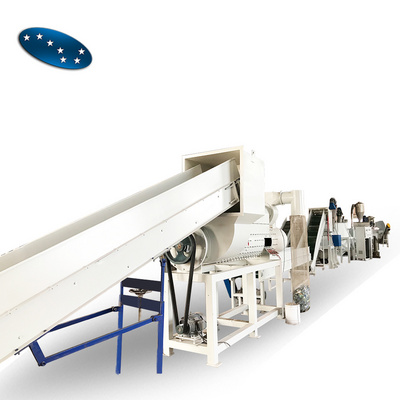

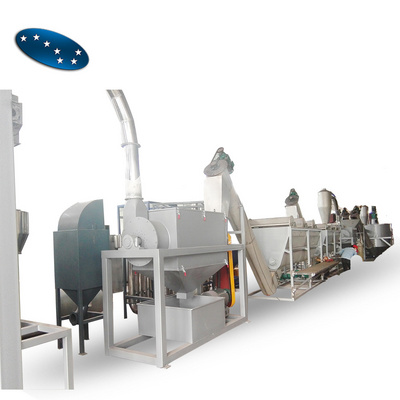

Process:Bale opener - Belt conveyor - Wet crusher - Hot washer - Floating tank - Screw feeder- Dewatering machine - Dryer -Blower - Silo

Product feature:

1. High automation, Less man power, low energy consumption, high output.

2. Provide whole solution for by-products during production, for example: variegated bottles, non-PET material, sewage water, labels, caps, metal and etc.

3. With a materials pre-treatment system such as Pre-washer, Label processing module, highly improve quality of end products .

4. Through multiple cold flotation, hot washing and friction washing, fully remove the impurities, such as glue, organic and inorganic residue.

5. The reasonable process design, reduce maintenance cost and bring convenient operation.

6. Impurity separation effect (customer feedback):

I) Moisture content: 1% max

II) Final PET density: 0.3G / CM3

A-PVC content: 50ppm

B-metal content: 20ppm

C-PE / PP content: 100 ppm

IV) Final PET size: 14-16 mm