NaN / 0

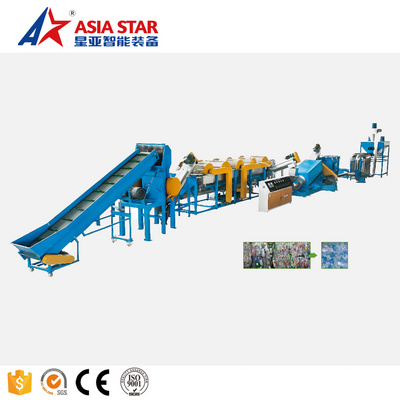

Plastic bottle recycling machine pet crushing washing drying recycling line pet bottle flakes hot washing recycling machine

Get Latest Price

US$ 70000

≥1 Sets

US$ 60000

≥2 Sets

US$ 54000

≥3 Sets

Quick Details

Machine Type:

PET Bottle Washing Line

Max.Production Capacity (kg/h):

5000

Place of Origin:

Jiangsu, China (Mainland)

Brand Name:

KOOEN

Product Details

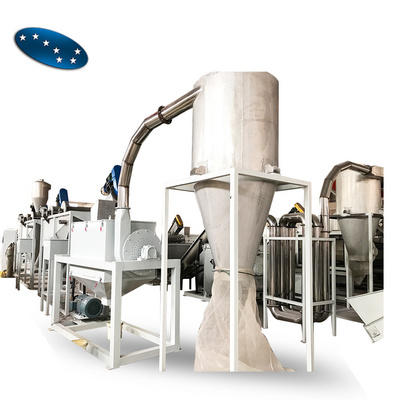

Plastic bottle recycling machine pet crushing washing drying recycling line pet bottle flakes hot washing recycling machine

PET Plastic bottle crushing washing and drying line /waste bottle recycling machine

Estimated Plant Parameters:

|

Model |

CAPACITY (kg/h) |

POWER CONSUMPTION (kw) |

WATER CONSUMPTION (ton/h) |

Manpower |

HUMIDITY CONTENT |

|

MT-300 |

300kg/hour |

150kw |

3ton/h |

4 |

<1% |

|

MT-500 |

500kg/hour |

230kw |

4-5ton/h |

4 |

<1% |

|

MT-1000 |

1000kg/hour |

270kw |

6-7ton/h |

5-6 |

<1% |

|

MT-2000 |

2000kg/hour |

370kw |

8ton/h |

5-6 |

<1% |

|

MT-3000 |

3000kg/hour |

420kw |

10ton/h |

7 |

<1% |

Working Flow of Waste Plastic PET bottle washing recycling machine:

Belt conveyor → Bale opener machine → Belt conveyor → Pre-washer (trommel) →Belt conveyor → Mechanical label remover → Manual separating table → Metal detector →Belt conveyor → Crusher *2→ Screw conveyor*2 → Floating washer →Screw conveyor → Hot washer chamber *2 →Screw conveyor*2 → High speed friction machine → Screw conveyor → Floating washer → Screw conveyor →Floating washer → Screw conveyor → Horizontal dewatering machine → Drying pipe system → Zig zag air classification system → Storage hopper → Control cabinet

Main Components of PET bottle flakes washing machine:

|

Belt conveyor: Control method: frequency control Belt material : PVC |

|

Bale opener machine

Stirring motor:

7.5kw*2

|

|

Trommel (pre washer): Dimension(L*W): 5000*1500mm; Material of barrel: Perforated plate, galvanized treatment |

|

Mechanical Label remover machine: Motor Power: 11/22/37KW ; Blade material: Tungsten steel, removable. Removing labels from bottles, label remove rate reach 99% ; Our label remover machine can workin with water, or without water for option; |

|

Crusher:

Motor power:

37/55/90kw

, Knife material:

SKD-11(from Japan), crushing with water:

|

|

Floating washer tank: Dimension(L*W): 4500*1500mm , Made of SUS304 stainless steel |

|

Hot washing chamber: Diameter of the barrel: 1800/2200mm , Heating type: Electric heating /Steam heating for option |

|

High speed friction machine: Motor power: 22/37/45Kw , Rotation speed 1200rpm; M ain shaft through dynamic balance treatment |

|

Floating washer tank (the second one ): Dimension(L*W): 4500*1500mm , Made of SUS304 stainless steel |

|

Floating washer tank (the third one): Dimension(L*W): 4500*1500mm , Made of SUS304 stainless steel |

|

Horizontal dewatering machine: Motor power: 22/37/45kw , Rotation speed reach 1500rpm, get rid of water; M ain shaft through dynamic balance treatment |

|

Zig zag air classify system: Remove the labels and small dirty at last step |

|

Storage hopper: Volume: 2.5m3, made of stainless steel |

|

Control cabinet: World famous brand electric components; |

(KOOEN company more plastic recycling machine for reference)

Related Products

PE/PP film washing line (with squeezer machine)

http://www.kooenmachine.com/pe-pp-film-washing-line-2/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/pe-pp-film-bags-washing-line-video/ (Video link)

PE/PP film washing line (with centrifugal dryer)

http://www.kooenmachine.com/pe-pp-film-washing-line-2/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/pe-pp-film-bags-washing-line-video/ (Video link)

HDPE, PP bottle(hard plastic) washing line

http://www.kooenmachine.com/hdpe-pp-rigid-plastic-washing-line/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/hdpe-pp-bottle-washing-line-video/ (Video link)

PET bottle washing line

http://www.kooenmachine.com/pet-bottle-washing-line/ (Website link)

http://www.kooenmachine.com/plastic-washing-line-video/pet-bottle-washing-line-video/ (Video link)

ZL series single stage compactor granulator

http://www.kooenmachine.com/zl-single-stage-pepp-film-compactor-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/zl-sereis-compactor-pelletizing-machine-video/ (Video link)

ZL series double stage compactor granulator

http://www.kooenmachine.com/zl-double-stage-pepp-film-compactor-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/zl-sereis-compactor-pelletizing-machine-video/ (Video link)

SJ series double stage granulator (water ring cutting)

http://www.kooenmachine.com/sj-single-stage-pepp-film-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/sj-series-pelletizing-machine-video/ (Video link)

SJ series double stage granulator (pull strip cutting)

http://www.kooenmachine.com/sj-single-stage-pepp-film-pelletizing-machine/ (Website link)

http://www.kooenmachine.com/plastic-pelletizing-machine-video/sj-series-pelletizing-machine-video/ (Video link)

http://www.kooenmachine.com/squeezer-machine/ (Website link)

http://www.kooenmachine.com/recyling-machine-auxiliary-machine-video/plastic-squeezer-machine-video/ (Video link)

http://www.kooenmachine.com/shredder-machine-crusher-machine/ (Website link)

http://www.kooenmachine.com/shredder-machine-crusher-video/ (Video link)

For choosing proper machine and saving your time, please read these bellow guides carefully:

1. What capacity(kg/hour) of this pet plastic bottle washing recycling line? please let me know..

2. You need the PET washing line (crushing washing drying line)? or PET flakes granulating machine? or the whole line (washing line + pelletizing machine)?

3. any special requirement? for example, do you need baler opener? color separator? etc..

Note, If you want to see more information (video) of this waste pet plastic bottle washing line/ recycling pelletizing machine , please log on our website https://kooengroup.com/case/

Plastic bottle recycling machine pet crushing washing drying recycling line pet bottle flakes hot washing recycling machine