NaN / 0

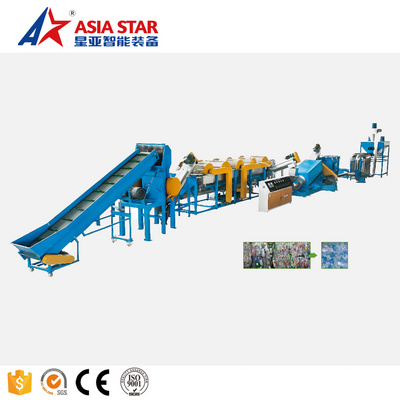

PP PE Film Bag Crushing Drying Recycling PET Bottle Automatic Line Waste Plastic washing Machine

Get Latest Price

US$ 35000

≥1 Sets

US$ 32000

≥3 Sets

Quick Details

Machine Type:

PP PE Bottle Washing Line

Max.Production Capacity (kg/h):

1000

Place of Origin:

Zhejiang, China

Brand Name:

hopesun

Product Details

Product Description

1. This mineral water bottle recycling mainly used for dealing with waste PET bottle, barrel etc.

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This PET bottle washing machine is composed of separator, crusher, cold & hot washing system, spin-dryer, drying, packing system, etc.

4. Easy to operate,Full automatic.

Working flow

Conveying PET bottle→label remover→ manual sorting table → wet crusher→screw loader →Hot washer→screw loader→high speed friction washer→screw loader→floating washer→screw loader→spray washer →spin-dryer machine → pipe line dryer → label separator → blower → hopper

|

Product capacity |

300kg/h |

500kg/h |

1000kg/h |

1500kg/h |

|

Workshop(L*W*H) |

40m*7.5m*6m |

42m*10m*6m |

70m*12m*6m |

75m*15m*6m |

|

Needed worker |

3-4 persons |

5-6persons |

7-8persons |

10-12persons |

|

Water supply (recycle use) |

2-3ton/h |

3-5ton/h |

7-10ton/h |

10-15ton/h |

|

Final product |

Moisture: max 3% Particle size: 10-18mm Metal content: max.20ppm Total impurity: 100-320ppm

|

|||