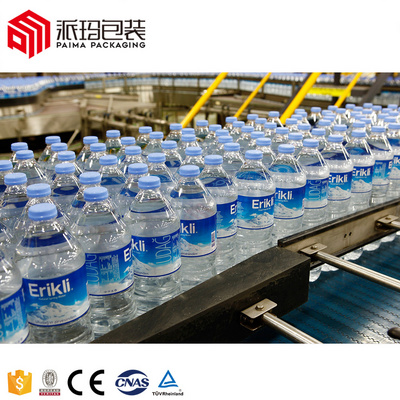

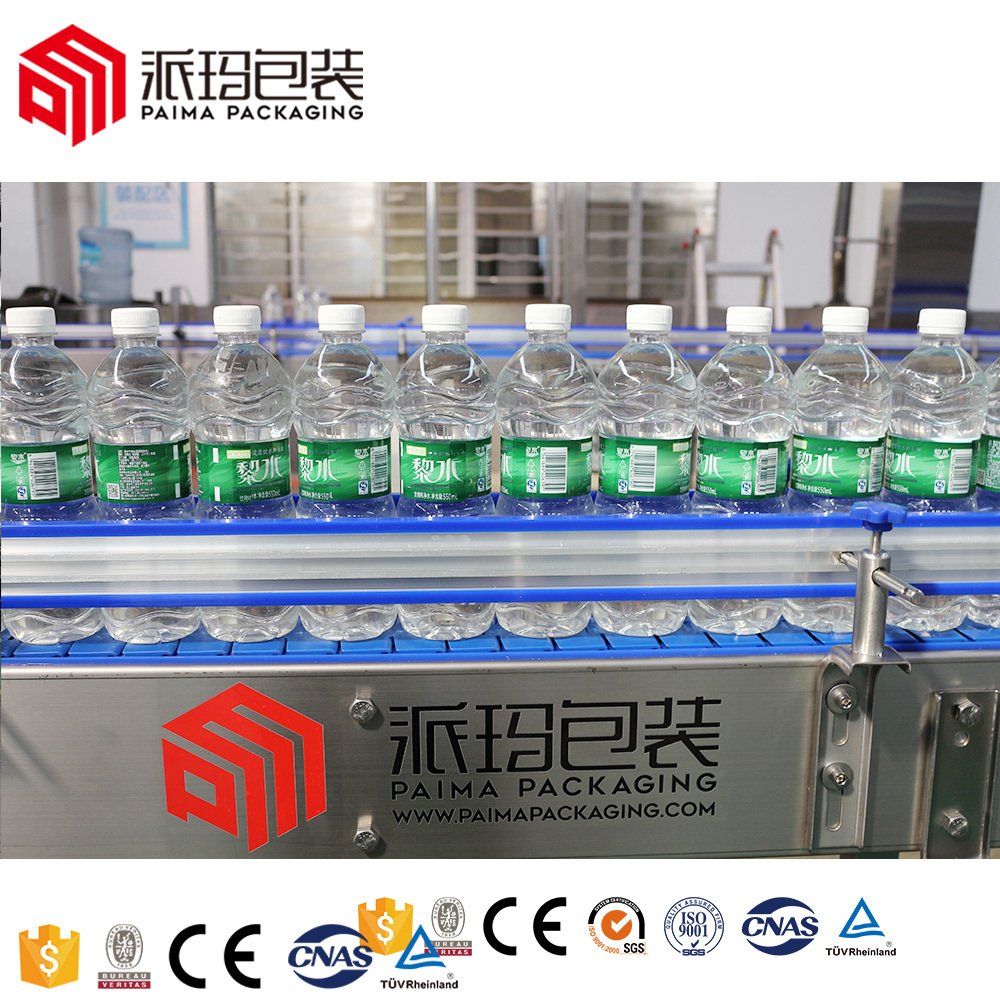

Bottle Material: Plastic Bottle

Cap: PE

Bottle Volume: 100-2500ml

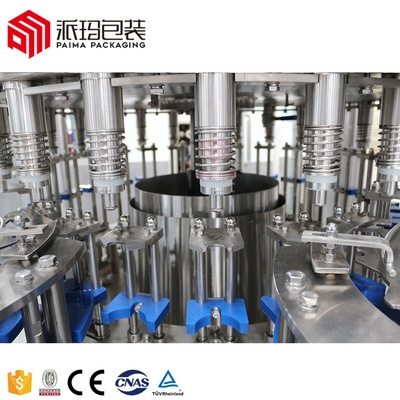

Production Speed: 1000-32000bph

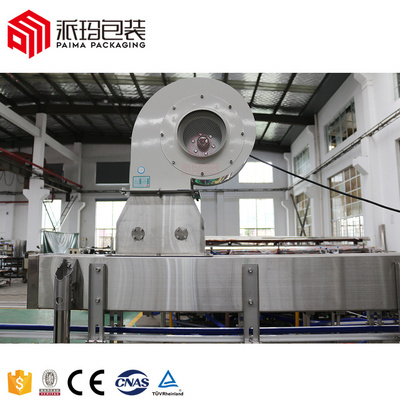

Suitable Bottle:

Height 170-320

Diameter 20-100