NaN / 0

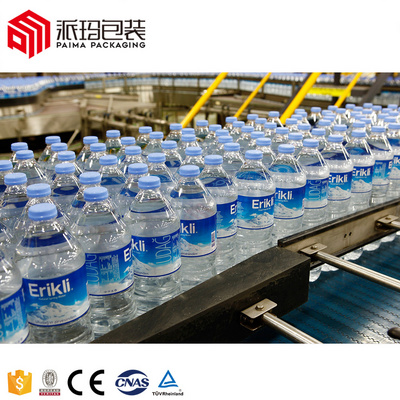

A TO Z Water Production Line / Drinking Water Making Machine / Pure Water Filling Machine

Get Latest Price

US$ 14735.2

≥1 Sets

US$ 12846.6

≥2 Sets

Quick Details

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 16000BPH, 2000BPH, 1000BPH

Packaging Material:

Plastic, Metal, Wood

Filling Material:

Beer, Milk, Water, Oil, Juice, Powder

Filling Accuracy:

±0.1%

Product Details

A TO Z Water Production Line / Drinking Water Making Machine / Pure Wate Filling Machine

CGF series water filling machine- Washing filling capping 3-in-1

Product introduction: This machine is mainly used for the filling of pure water, mineral water and other non-gas and sugar-free beverages in plastic bottles. It is an integrated equipment for washing, filling and sealing.

Capability character: it adopts hanging type air conveyor to make change bottle model more convenient, faster and cleaner. the main machine adopts advanced PLC control technology, the key electric elements adopt international famous products or according to customer's customized.

1)It is adopted that direct connection between air conveyor and inlet starwheel instead of screw and conveyor chains, which is easier for bottle changing.

2)There is no need to adjust the height of equipment through neck holding tech for bottle transportation.And what is only to change some spare parts.

3)High speed filling line is of clamp transferring technology.Bottle shapes are more varied, and the working table inside the machine is more laconic.

4)By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier.

5)Specially designed stainless steel bottle clamp dose not contact the thread parts of the bottle neck, avoiding the second contamination.

6)High speed and large flow filling valve assures the high filling speed and exact fluid level.

7)Parts contact with the liquid are all of excellent stainless steel or food level plastic.The electric system is of international brand and achieves the national food sanitary standard.

8)The bottle-out starwheel is of screwdown shape.When bottle size is changed, there is no need to adjust the transferring chain's height.

| Item | Parts name | Brand | Country |

| 1 | PLC |

SIEMENS |

Germany |

| 2 |

Inverter |

SIEMENS |

Germany |

| 3 | Touch screen | SIEMENS |

Germany |

| 4 | Switch | SIEMENS |

Germany |

| 5 | Contactor | SIEMENS |

Germany |

| 6 | Relay | SIEMENS |

Germany |

| 7 |

Solenoid Valve |

AIRTAC |

Taiwan |

| 8 | Drive motor |

FEITUO |

Swiss |

| 9 | Reducer | SKF | China |

| 10 | Water Pump | CNP | China |

| 11 | Main bearing |

AUTONICS |

Sweden |

| 12 | Sensor | AIRTAC |

Taiwan |

| 13 |

Air component |

ABB |

Taiwan |

| Model | CGF8-8-3 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-10 |

|

Capacity (500ml/bottle/h) |

1000-2000 | 2000-4000 | 5000-8000 | 8000-12000 | 12000-15000 | 15000-20000 |

| Suitable bottle shape | Round bottle or square bottle | |||||

| Bottle diameter(mm) | 49-116 | |||||

| Bottle height(mm) | 160-320 | |||||

| Compressed air pressure(Mpa) | 0.2-0.8 | |||||

| Washing medium | Pure water | |||||

| Washing water pressure(Mpa) |

>0.06MPa ≤0.2MPa |

|||||

| Total power(KW) | 3.8 | 4.5 | 4.8 | 5.5 | 7 | 8.2 |

|

Overall dimensions (mm) |

2200*1600*1800 | 2400*1880*2000 | 2800*2200*2300 | 3050*2400*2300 | 3800*2600*2500 | 4000*3150*2500 |

| Weight(KG) | 2880 | 3050 | 4300 | 6400 | 7450 | 8550 |

|

Water treatment system: Simple operation,Less maintenanceand Lower power cosumptionrefers, to the measures taken to make the water quality meet certain use standards. The physical characteristics of water, such as temperature, color, transparency, odor and taste, are filtered or treated so that water can be used directly for drinking or other purposes. Different water sources with different equipment configurations. We will jointly choose the most suitable water treatment system for you! |

|

|

Automatic labeling machine:

|

|

| Automatic shrink wrapping packing machine: Specially designed for beverages, pure water, fruit juice, wine and other drinks. With full automatic functions of bottle transfer and arrange, film wrapping, sealing and cutting, shrinkage, cooling and other qualities. It adopts the world's advanced film thermostatic sealing technology, and the sealing is firmly cleaned. The PLC program is used for automatic circulation control, and the performance is stable and reliable. | |

|

Automatic bottle blowing machine:

1. Excellent Mechanical Strength, impact-resisting, and non-craking. 2. Bottle mouth and thread are of precise measurement. 3. Plastic Customized Bottle's safe thread can be molding directly. 4. The size and weight of the product can calculate and design clearly and meet the requirement of the design without any deviation. |

We are not only a filling equipment manufacturer, but also design and build factories, equipment layout, circuit layout and equipment operation schemes. Our equipment is designed carefully, easy to use and easy to manage. Whether you need a machine or a complete filling and packaging system, we have rich experience to ensure the successful completion of your project.

Honor Machine

provides the wide range of liquid filling capabilities and industry experience while delivering the lower cost of ownership for our customers.

We are not only a filling equipment manufacturer, but also design and build factories, equipment layout, circuit layout and equipment operation schemes. Our equipment is designed carefully, easy to use and easy to manage. Whether you need a machine or a complete filling and packaging system, we have rich experience to ensure the successful completion of your project.

Since 2008, Honor Machine has been one of the leading suppliers of packaging technology. Located in the beautiful city of Zhangjiagang, Jiangsu Province, a new port city famous for professional industrial city. We are committed to:

1)Automatic industry water treatment system(Reverse Osmosis, Ultrafiltration)

2)All kinds of beverage filling and packaging production lines (water, juice, carbonated drink, all kinds of liquors)

3)3-10L beverages filling and packaging production line

4)3-5 gallon beverages filling and packaging production line

5)Alcohol/beer filling and packaging production line

6)All kinds of Edible Oil and Oil Filling and Packaging Production Lines

7)All kinds of sauce filling and packaging production lines (honey, jam)

8)Zip-top can filling and packaging production line

9)Automatic/Semi automatic bottle blowing system

10)Automatic injection blowing/ Extrusion blowing machine

Your Success Is Our Mission!

Q1.How to tell us your enquiry?

A1:You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

Q2:Are you a factory or trading company?

A2:We are a factory, professional water treatment system manufacturer and bottled water filling & packing machinery with about 7 years experience. Factory covers an area of 5,000 square. There have been more than 50 countries use our products.

Q3.Where is your factory?

A3:Our factory is located in NO.198 Zhenbei Road Leyu Town,Zhangjiagang City,JiangSu Province,China, it is near to Shanghai or Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

Q4.How about after-sale service?

A4:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.After the commissioning, we will package the equipment by standard export package for shipment.

Q5:How long is the warranty of your equipment and installation?

A5:2 years warranty after receipt check upon delivery.

We will send our professional engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back,accommodation and USD120 / day/person.

Q6:What is the features of our company?

A6: We provide turnkey project for customers, including sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training etc

Q7:How to guarantee your funds to be safe and delivery to be on time?

A7:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

Hot Searches