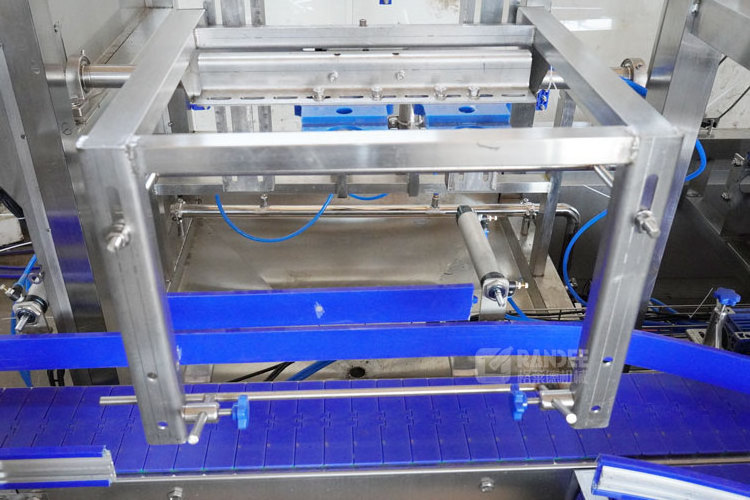

(1)water filling line/liquid filling line includes: Washing-filling-capping 3 in 1 machine, lamp inspection, label shrinking

machine, inkjet printer, hot shrink film packer and conveyors. It is a full automatic production line.

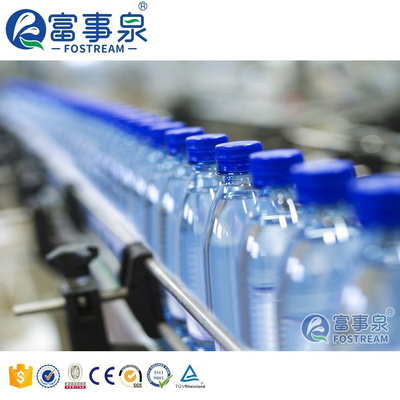

(2)The water filling line is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

(3)The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

(4)The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machinery of the same specifications.

(5)The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

(6)It is convenient to operate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.