NaN / 0

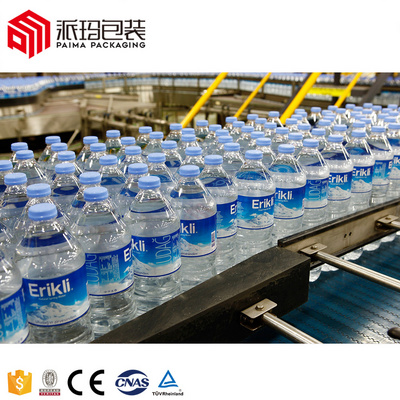

A to Z Automatic Complete Bottled Pure Drinking Mineral Water Filling Production Line Bottle Water Filling Machine

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 24000BPH, 30000BPH, 36000BPH, 40000BPH

Packaging Material:

Plastic, Glass

Filling Material:

Water

Filling Accuracy:

99.5%

Product Details

Product Overview

Full automatic water filling machine for PET bottle integrates the functions of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of mineral water, pure water, drinking water etc.

|

Model

|

XGF14-12-5

|

XGF16-16-5

|

XGF24-24-8

|

XGF32-32-8

|

XGF40-40-10

|

||||

|

Capacity

(for 500ml)

|

5,000BPH

|

8,000BPH

|

12,000BPH

|

15,000BPH

|

18,000BPH

|

||||

|

Bottle diameter

|

50~110mm

|

|

|

|

|

||||

|

Bottle height

|

160~310mm

|

|

|

|

|

||||

|

Air source pressure

|

0.7MPa

|

|

|

|

|

||||

|

Voltage

|

380/415V

|

|

|

|

|

||||

|

Main motor power

|

1.5KW

|

2.2KW

|

3.0KW

|

4.0KW

|

7.5KW

|

||||

|

Dimension

|

2360*1770*2700

|

2760*2060*2700

|

2800*2230*2700

|

3550*2650*2700

|

4360*3300*2700

|

||||

Product Features

1. This water filling machine has a compact structure, perfect control system, easy to operate and highly automated.

2. Only by changing the star-wheel, arch board can realize fill bottle shape change.

3. The parts contact with product is made of quality SUS316/304, anti-corrosive, and easy to clean.

4. Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

5. The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

6. This water filling machine has a high efficient cap arranging system, perfect cap feeding with self-control and self-protection device.

7. The water filling machine adopts perfect overload protective device can ensure the operator and machine safety.

8. The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc.

9. The main electric and air-drive components are world famous brand products.

10. All control is advanced touch-screen operation and realize people-computer dialogue operation.

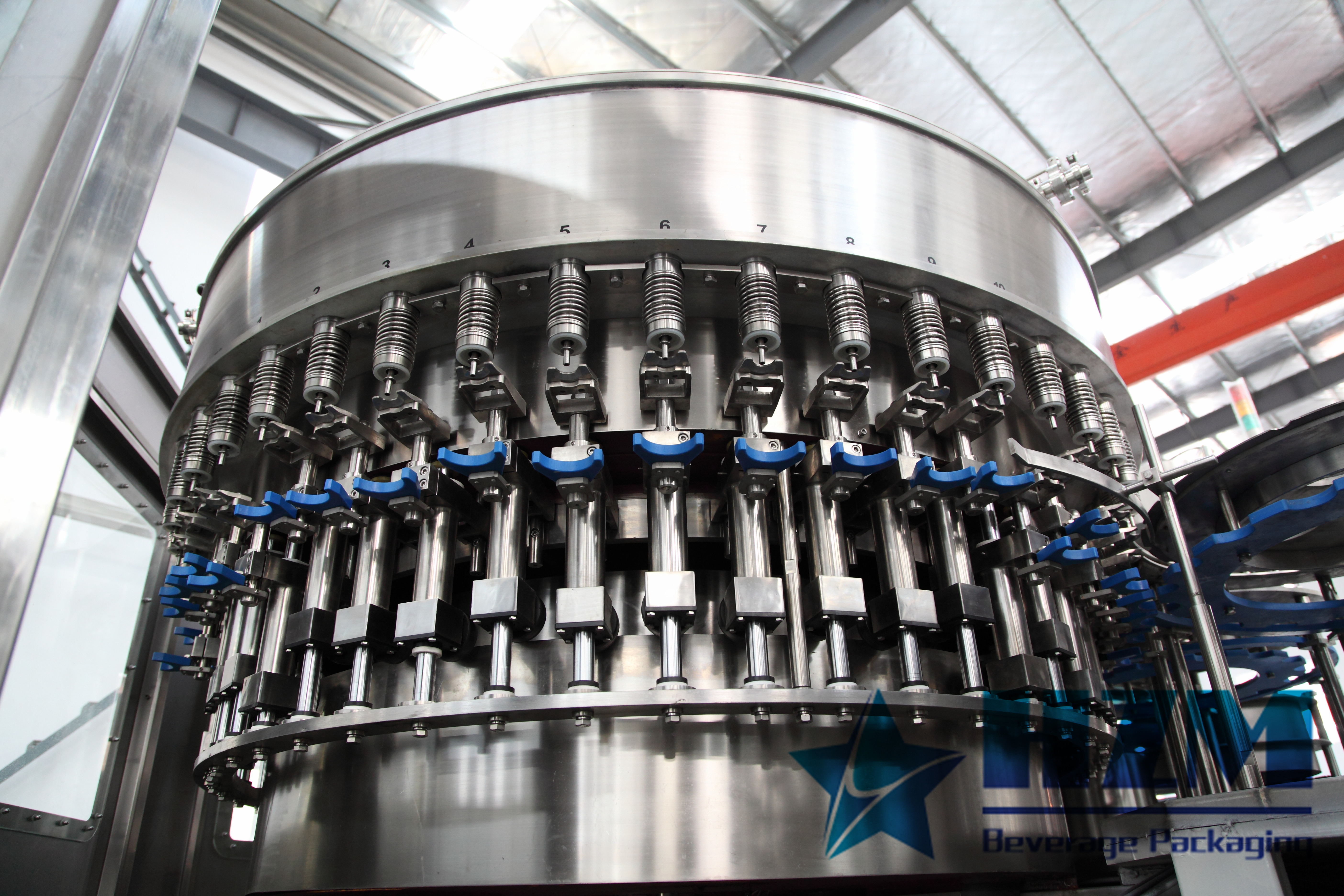

Rinsing Part

1. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

2. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, saving rinsing water.

3. Covering of bottle clamps and elevator are product of Igus.

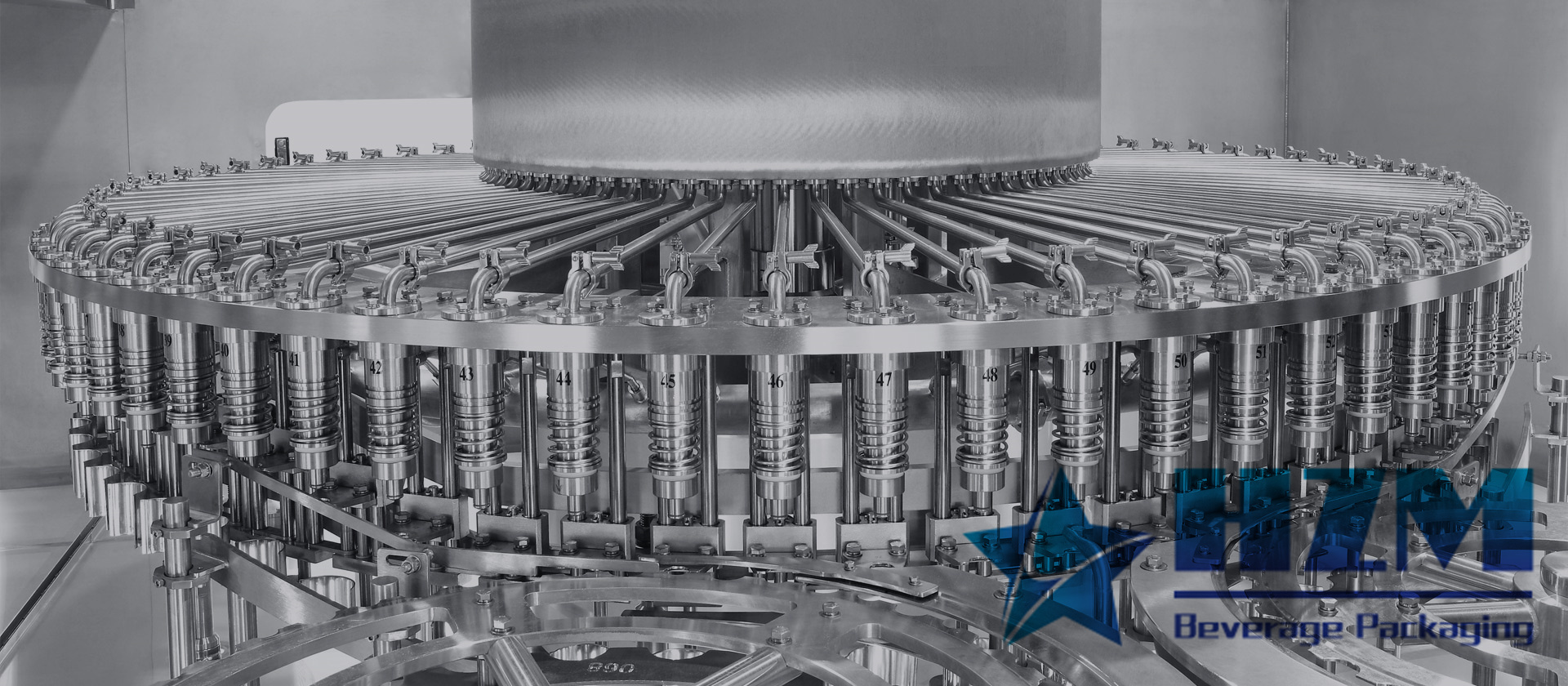

Filling Part

1. Filling valves are designed and manufactured with German technology, featuring high filling accuracy and high filling speed.

2. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

3. Filling valves are made of SUS316.

4. Hydraulic pump is float-ball controlled.

Capping Part

1. Highly effective acentric way for cap sorting to reduce the abrasion.

2. The fall guide rail has the device to prevent the reversal cap from passing and pick out the reversal cap.

3. It has the bottle check-up switch to control the cap flow and stop it in case no bottle to reduce the cap quantity.

Product Configurations

|

Item

|

Remark

|

|

Main motor+ Reducer

|

SEW-Germany

|

|

Inverter

|

SIEMENS-Germany

|

|

PLC

|

SIEMENS-Germany

|

|

Touch screen

|

SIEMENS-Germany

|

|

Contactor

|

SCHNEIDER-France

|

|

Hot relay

|

SCHNEIDER-France

|

|

Air switch

|

SCHNEIDER-France

|

|

Photoelectric switch

|

LEUZE/BANNER-Germany

|

|

Pneumatic components

|

FESTO-Germany

|

|

Sliding bearing

|

IGUS-Germany

|

|

Lubrication system

|

BEKA-Germany

|

Complete Production Line Solution

Water Treatment purify system for mineral water, pure water and other bottled water for food and beverage industry. It's maunly composed of the following equipment: pre-treatment, membrane system, electrodialysis device, sterilization system etc. The raw water can be ground water, sea water, tap water or the other water source, we choose suitable purify system based on raw water quality. The capacity usually from 1T to 200T per hour.

Bottle blow molding machine is used to make containers for product, PET preforms are heate by lamps and then blowed by high pressure clean air within mold. It will become a bottle container as you designed. The blow molding machine capacity normally from 3,000BPH to 24,000BPH.

Bottle filling machine is a fully automatic multifunctional combined unit consisting washing, filling and capping. The bottle filling machine is the step of put materials into containers and seal it. It's very important and sensitive for quality control. The filling machine capacity in our industry normally start from 3,000BPH up to 36,000BPH.

There are different production, such as BOPP labeling, sleeve and shrink labeling and adhevise labeling etc. The capacity for labeling machine starts from 2,000BPH up to 42,000BPH, we can choose different but suitable ways for customers.

Bottle packing machine is the last step for production line usually. There are different ways for packing such as shrink packing, carton packing, half- tray wuth shrink packing etc. Bottle packaging machine speed usually from 10PPM up to 80PPM, all confirgurations we used are world famous brand, to ensure the machine quality.

Related Products

Why Choose HZM

Huazhen Machinery (HZM) Co., Ltd. is located in the Machinery Industry Park of Jinfeng Town, Suzhou City. It has an international standard plant with an area of about 10,000 square meters. We're a comprehensive professional supplier of liquid beverage packaging machinery, which integrates development, manufacture and sales. HZM quality not only meets the requirements of the national machinery industry, also achieves CE/ISO and other international quality management system certification level. At present, the equipment is exported to domestic and overseas markets more than 30 regions and countries.

Turnkey Solution Service

High-quality equipment, perfect service, abundant operation of the whole plant, strong turnkey service capability of the wholeplant, HZM helps customers achieve a high-efficiency operation of equipment.

High-quality equipment, perfect service, abundant operation of the whole plant, strong turnkey service capability of the wholeplant, HZM helps customers achieve a high-efficiency operation of equipment.

Installation / Debugging / Training

After the customers received the equipment, HZM will send experienced engineers to the customer's factory to do installation and commission services, and provide theoretical and technical training.

After the customers received the equipment, HZM will send experienced engineers to the customer's factory to do installation and commission services, and provide theoretical and technical training.

After-Sales Service

HZM meets customer requirement in the shortest time with a complete service platform and fast response mechanism.Provide 7*24 hours after-sales service, comprehensive after-sales protection, timely and effective problem solving mechanism.

HZM meets customer requirement in the shortest time with a complete service platform and fast response mechanism.Provide 7*24 hours after-sales service, comprehensive after-sales protection, timely and effective problem solving mechanism.

Spare Parts

Providing one-stop spare parts management service solutions, including unified order acceptance, reliable spare parts supply, first-class logistics network, professional service delivery management, to ensure the spare parts are sent to the right place at the right time.

Providing one-stop spare parts management service solutions, including unified order acceptance, reliable spare parts supply, first-class logistics network, professional service delivery management, to ensure the spare parts are sent to the right place at the right time.

HZM Customers

FAQ

Q1:How can you guarantee the quality if I order from HZM?

1. Before assembly, we will strictly test each component to ensure the accuracy.

2. We will arrange experienced engineers to be responsible for each equipment.

3. We will test each equipment continuously for at least 12 hours before shipment.

Q2:What's your guarantee rules?

We provide quality machines with top brand components and qualified material. Our warrantee time is 2 years after installation and commissioning. Within 2 years the machines get quality problem, we will take full responsibility and provide services.

Q3:Can you provide installation service?

Yes, according to customers' requirement, we can provide on-line support or send engineers to customer's factory to do installation, commission and training.

Q4:Do you provide customized service?

Yes, we can help customers design factory layout, production layout, bottle type etc. We can also provide transformer, stablier, cabel, label, preform and other necessary materials.

2. We will arrange experienced engineers to be responsible for each equipment.

3. We will test each equipment continuously for at least 12 hours before shipment.

Q2:What's your guarantee rules?

We provide quality machines with top brand components and qualified material. Our warrantee time is 2 years after installation and commissioning. Within 2 years the machines get quality problem, we will take full responsibility and provide services.

Q3:Can you provide installation service?

Yes, according to customers' requirement, we can provide on-line support or send engineers to customer's factory to do installation, commission and training.

Q4:Do you provide customized service?

Yes, we can help customers design factory layout, production layout, bottle type etc. We can also provide transformer, stablier, cabel, label, preform and other necessary materials.

Hot Searches