NaN / 0

small industrial milk powder processing plant factory spray dryer making machine/dairy equipment/milk powder production line

Get Latest Price

US$ 68000

≥1 Sets

Quick Details

Place of Origin:

Shanghai, China

Brand Name:

Genyond

Voltage:

380V

Power:

100kw

Product Details

Product Description

Powdered milk or dried milk is a manufactured dairy product made by dehydrating liquid milk through several drying processes until it is a powder.

One purpose of drying milk is for easy preservation; milk powder has a far longer shelf life than liquid milk and does not need to be refrigerated.

Similar to raw milk, powdered milk is loaded with nutrients; it is a good source of essential minerals and vitamins such as magnesium, calcium, zinc, potassium

as well as vitamins A, D, E and K. During the evaporation process, it is ensured that these beneficial nutrients are not lost. Milk powder also meets your daily dose

of other important nutritional elements such as amino acids which are responsible for a number of functions such as cellular growth, stimulating the body’s immune system,

aiding in blood clotting, calcium absorption and so on.

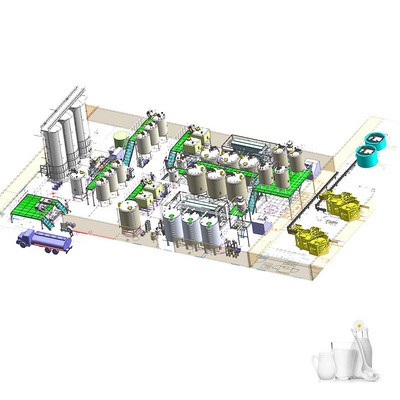

With solutions ranging from 500.000 litres of milk per day up to 2.000.000 litres of milk per day, GENYOND can accompany full milk powder plants. also vary from dairy milk,

coconut milk, soybean milk powder etc different product for market.

1 Milk receiving stage

2 Fresh milk pro-processing stage

3 Condensed milk processing stage

4 Spray drying processing stage

5 Packing processing stage

6 CIP system.

Remark for technics

1. Milk receiving technics

Fresh milk is collected from milk tank car mostly, a small parts is from leglin. The fresh be tested by

density, acidity, temp er ature, fat. The certified milk will be filtrate and measured, then be stored in temporary tank. The milk cooling down by PHE to storage tank or next stage.

2 milk pre-processing technics

a. For whole milk powder: milk from storage tank, after measured to temporary tank. Be transferred to condense stage by pump.

b. For whole sugar powder: Milk from storage tank, be transferred to PHE by pump after measure. Heating to 45-60 ℃ and be feed to mixing tank. Dissolving sugar and feed to sugar tank. Sugar s y rup mixing with milk in mixing tank, and be feed to temporary tank.

c. For whole mixing powder: Milk from storage tank, be transferred to PHE by pump after measure. Heating to 45-60 ℃ and be feed to mixing tank. Dissolving additive and feed to temporary tank. mixing with milk in tank, after homogenizer in 15Mpa pressure be feed to temporary tank.

3 condense technics

Transfer milk(12%) to balance tank of evaporator, heating and to 2ed effective heating room,

then go to 1st effective heating room. The sterilizing temperature is 86~94 ℃ , keeping time for 24 seconds, then go to first effective evaporate room (temperature is 68-70 ℃ ) , transferred by pump to second effective room( temperature is 46-50 ℃ ). The consistency could be 45%.

4 Spray drying technics

Condensed milk(45%) be transferd by high pressure pump to drying tower. The milk be sprayed to mist state and meet the hot wind(160~170 ℃ ),become powder quickly and flow down to cone bottom of the tower, then go to flow bed dryer and mixing with lecithin(1%), the small powder will be big and drying, cooling down to 30~35 ℃ and in powder tank.

5 packing technics

The milk powder be feeded to packing machine by air, after packing in bags and transferred

by conveyer to storage room. Form milk to powder, all of them in closed equipment, So

without any pollution.

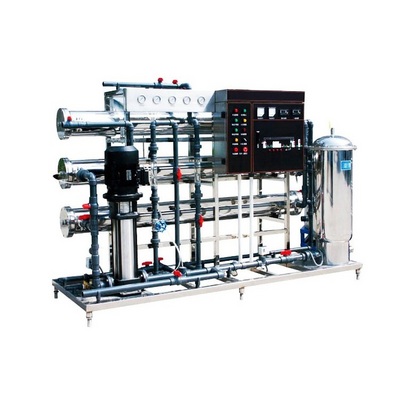

6 CIP system

CIP is controlled by PLC, the liquid level,temperature,acidity is monitored. All

equipment ,piping,valves could by clear by CIP. The evaporator clear by themselves system.

Drying Tower cleared by pressure pump and warm water.

5.7 Control system

All line is controlled by computer with PLC. The main data is flux, temperature and liquid level. All control is done in control room.

About US

GENYOND MACHINERY INDUSTRIAL GROUP

It has 6 factories in China for food machine and packing machine.

Shanghai Genyond Technology Co Ltd; Zhangjiagang Genyond Machinery Co Ltd

Shanghai Jou Yu industrial Co Ltd; Shanghai Keyfood Machinery Co Ltd

Sino topone machinery; Nantong Yihai Machinery; Kunshan Kpack Machinery

Our products have been exported to more than 160 countries with Annual sales reaching 80 millions in 2022 and it raises by yearly average 10% above.

Genyond machine has more than 100 engineers for the installation of oversea projects.

You just need to give us your idea on final product to be made, processing capacity, way of packing, we will make the proposals for your checking. You can also give us your budget, we can also design a line to meet your budget accordingly.

A satisfying project will be given; A long-term cooperation will come.

WHY CHOOSE US?

FAQ

Our Services

SHANGHAI GENYOND TECHNOLOGY CO.,LTD.

GENYOND MACHINERY INDUSTRIAL GROUP

Tel : +86 21 34796126

Mob: +86 18217773391

Skype:genyondmachine5

Add : No. 1328, Hengnan Road, Pujiang Town, Minhang District,Shanghai

Alibaba: http://genyond.en.alibaba.com

Hot Searches