NaN / 0

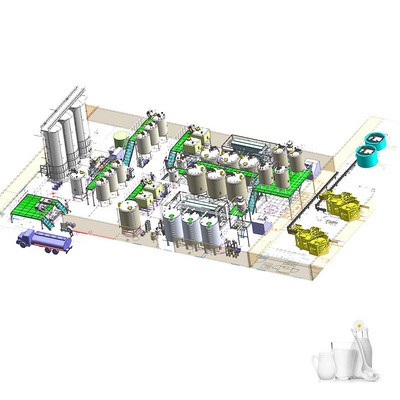

Dairy Making Machine/mini Milk Processing Plant/long Life Milk Production Line Machinery

Get Latest Price

US$ 49900

≥1 Pieces

Quick Details

Marketing Type:

New Product 2024

Place of Origin:

Shanghai, China

Brand Name:

Beyond

Voltage:

220V/380V/415V

Product Details

Dairy Making Machine/mini Milk Processing Plant/long Life Milk Production Line Machinery

Description of dairy processing milk plant

A dairy processing milk plant is a facility where raw milk is received and processed into various dairy products such as milk, cheese, butter, and yogurt. The main steps involved in dairy processing at a milk plant are:

-

Milk reception: Raw milk is received from local dairy farmers or milk collection centers. It is quality tested to ensure it meets the required standards before being accepted.

-

Pasteurization: The raw milk is then heated to a specific temperature for a certain duration to kill any harmful bacteria present. This process helps increase the shelf life of the milk.

-

Separation: The milk is passed through a centrifuge to separate the cream from the skim milk. The cream can be used to make butter or cream-based products, while the skim milk is further processed.

-

Homogenization: This step involves breaking down the fat globules in the milk to prevent cream separation. Homogenization ensures a consistent texture and prevents the formation of a cream layer on top of the milk.

-

Standardization: The milk is standardized by adjusting the fat content to meet specific regulations or customer requirements. This is done by adding cream or skim milk to achieve the desired fat percentage.

-

Cooling and storage: The milk is rapidly cooled to minimize bacterial growth and maintain its freshness. It is then stored in temperature-controlled tanks until further processing or packaging.

-

Processing into dairy products: The milk can be processed into various dairy products like cheese, yogurt, or butter. Different processes and ingredients are used depending on the desired final product.

-

Packaging: The processed dairy products are packaged in containers suitable for retail sale. The packaging is often done in aseptic conditions to maintain product freshness and extend shelf life.

-

Quality control: Throughout the entire manufacturing process, quality control measures are implemented to ensure that the final products meet all safety and quality standards. Samples are regularly tested in the laboratory for microbial, chemical, and sensory analysis.

-

Distribution: The packaged dairy products are then distributed to retailers, supermarkets, or food service establishments for sale to consumers.

Dairy processing milk plants play a crucial role in converting raw milk into safe, nutritious, and value-added dairy products for consumption. They require sophisticated equipment, skilled labor, and strict adherence to quality control standards to ensure product safety and consistency.

milk blending system milk pasteurizer and homogenizer

milk filling system product storage system

End product package of this dairy processing milk plant can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box, aseptic pouches etc . for this Milk processing line according to different end product and package type, the production technology is differently designed, but commonly include the following steps:

Equipment advantages

|

Equipment list of 25T/D dairy processing milk plant

( pasteurized milk\yogurt\cheese\cream\butter ) |

||

| NO. | NAME | MAIN TECHNOLOGY PARAMETER |

| 1 | MILK RECEIVE\STORAGE\AND CREAM SEPARETOR UNIT | |

| 2 | Electron pound scale | Maximum weighing 500KG |

| 3 | Milk weighing tank | Made of SUS stainless steal,single layer,product feeded in through 40 mesh filter net,CIP cleaning ball |

| 4 | Milk acceptor | SUS304 stainless steel,single layer,CIP cleaning ball |

| 5 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 6 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 7 | Dish separator | Auto residue discharge |

| 8 | Chiling tank | SUS304 stainless steel,alveolate jacket,attached with compressor |

| 9 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 10 | PREPARING UNIT | |

| 11 | Blending tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 12 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 13 | Mini set of plate-type heat exchanger | SUS304 stainless steel,two stages, |

| 14 | High speed emulsification tank | SUS304 stainless steel,heat insulated,bottom high speed emulsifier,digital readout thermometer,supporters with adjustable feet |

| 15 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 16 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 17 | Sterilizing,homogenizing unit | |

| 18 | UHT sterilizer | Tub-type,sterilzing temperature 137 C,holding time 4S,full automatic control |

| 19 | High pressure homogenizer | 40MPa,(starting box included) |

| 20 | Temperature holding | SUS304,holding 300S |

| 21 | Distributing plate | SUS304,3 holes |

| 22 | Cheese\butter processing unit | |

| 23 | Bufferying tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 24 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 25 | Cream seperator | |

| 26 | Bufferying container | SUS304,with cover |

| 27 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 28 | Butter-churner | SUS304,stepless timing |

| 29 | Cheese vat | SUS304,with heating jacket and insising device |

| 30 | Pressor | SUS304,6 heads |

| 31 | Mould | SUS304,10L,with cover |

| 32 | Yogurt fermentation unit | |

| 33 | Fermentation tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 34 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 35 | Plate cooler | SUS304,single stage,milk discharge at 4C |

| 36 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 37 | Filling unit | |

| 38 | Higher position tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 39 | Pasteurized milk filling machine | |

| 40 | Yogurt filling machine | |

| 41 | CIP system | |

| 42 | Semi-auto CIP system | Outer coat of SUS304 stainless steel material,inner shell of SUS316,single cleaning way,Concentrated acid/alcali tank adding system based on US technology, 100L×2 acid/alcali Concentrate tanks |

| 43 | CIP return pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 44 | I nstallation part | Whole milk processing line installation and commissioning |

Dairy production plants have significantly advanced with the integration of modern information technology (IT) to streamline operations, enhance food safety, and improve overall efficiency. Here's an overview of how IT is used in dairy production:

1. Automation Systems : Dairy plants utilize automation systems like Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) software for process control. These systems automate tasks such as raw milk reception, pasteurization, homogenization, separation, filling, and packaging.

2. Process Controls : Real-time monitoring of critical parameters such as temperature, pressure, flow rate, and composition (e.g., fat content, protein levels) is achieved through sensors and control systems. Automated adjustments ensure optimal processing conditions and product consistency.

3. Quality Control : In-line analysis tools are integrated into the production line to test the quality of milk and products at various stages, including chemical composition, microbiological status, and sensory attributes. This data feeds back into the system, allowing immediate corrective actions if necessary.

4. ERP Integration : Enterprise Resource Planning (ERP) software coordinates all aspects of the business from procurement of raw materials to sales and distribution of finished goods. It optimizes inventory management, production planning, and supply chain coordination.

5. Internet of Things (IoT) : IoT devices monitor equipment performance, detect maintenance needs, and optimize energy usage. They also help in cold chain management by tracking temperatures throughout storage and transportation.

6. Artificial Intelligence (AI) and Machine Learning : AI algorithms can analyze large datasets from production processes to predict yield, anticipate breakdowns, minimize waste, and refine product formulations. Machine learning can also be applied to sorting and grading raw milk based on its quality.

7. Traceability Systems : Barcode or RFID-based traceability solutions allow dairy producers to track every batch of milk from the farm to the consumer, ensuring compliance with food safety regulations and enabling swift recall procedures when necessary.

8. Laboratory Information Management System (LIMS) : A LIMS automates laboratory workflows, manages samples, analyzes test results, and generates reports to maintain regulatory compliance and quality standards.

9. Advanced Cleaning Systems : CIP (Cleaning-in-Place) systems are controlled by IT infrastructure to schedule and execute cleaning cycles effectively, ensuring hygiene and sanitation between batches.

10. Data Analytics : Comprehensive data analytics platforms compile and analyze operational data to identify trends, inefficiencies, and opportunities for cost reduction and sustainability improvements.

In summary, information technology has become a cornerstone in modern dairy production, transforming traditional manufacturing practices into highly efficient, safe, and sustainable operations.Advanced technology is an important component of our core competitiveness.

Pre sales services

After sales services

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.

Hot Searches