NaN / 0

dairy milk production line dry powder milk making machine/baby formula milk powder yogurt processing line

Get Latest Price

US$ 495000

≥1 Pieces

US$ 405000

≥3 Pieces

Quick Details

Marketing Type:

baby milk powder production line

Place of Origin:

Zhejiang, China

Brand Name:

JIMEI XUXIANG

Voltage:

220V/380V/440V

Product Details

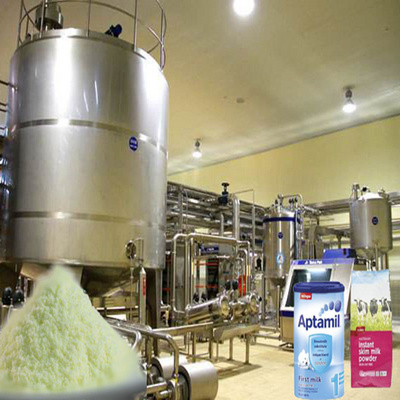

Dairy Milk Processing Plant

Our company is looking for the sole agent in every country. Welcome to negotiate.

Products Description

Final powder milk products for reference only.

we can make the final milk powder product according to your demand.

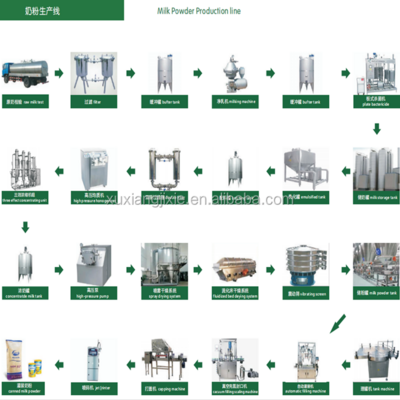

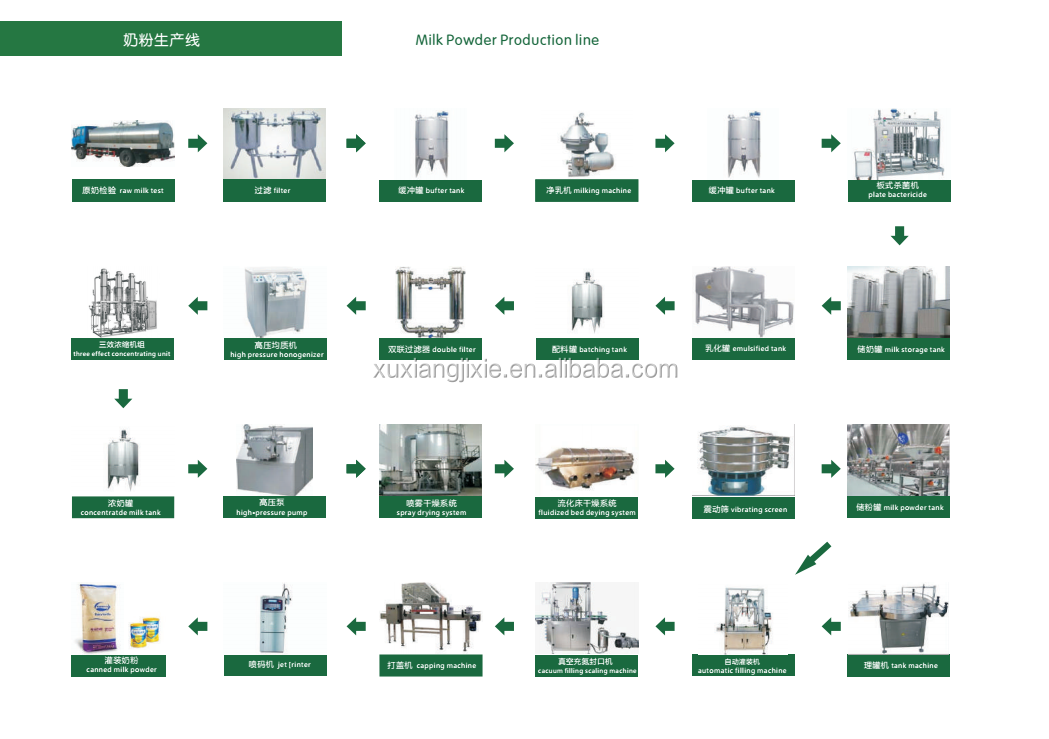

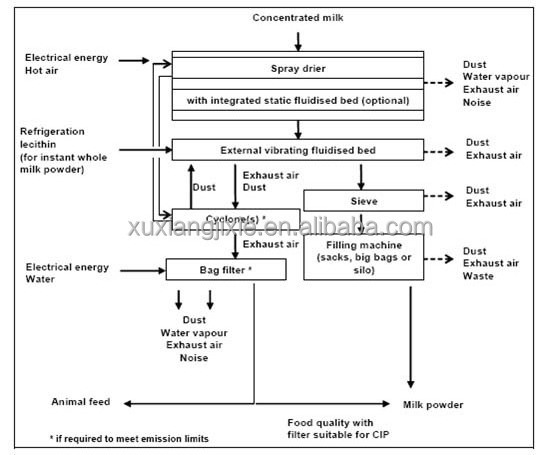

General Flowsheet of powdered milk products

The first stage in the production of condensed or powdered milk is the concentration of the raw milk. Homogenized milk is usually

concentrated with evaporators. Falling film evaporators are generally used followed by a drying step using a spray dryer. Doubling

of the concentration of milk and whey is common. The powder is typically agglomerated to improve reconstitution. Dry whole milk is

susceptible to oxidative rancidity and may be packaged in a protective atmosphere to extend its shelf-life.

concentrated with evaporators. Falling film evaporators are generally used followed by a drying step using a spray dryer. Doubling

of the concentration of milk and whey is common. The powder is typically agglomerated to improve reconstitution. Dry whole milk is

susceptible to oxidative rancidity and may be packaged in a protective atmosphere to extend its shelf-life.

* Two-stage drying in milk powder production:

a) Description of the technology:After the milk has been thickened from 11% to 50-60% dry matter in an evaporator, the condensed

milk may further be dried to 95-97% dry matter content. Spray driers or roller driers are used in milk powder processing. Although

roller driers may be found in the dairy sector and are sometimes useful for specialized products, spray driers with downstream or

integrated FBD’s have become more common. This is due to their low energy usage, primarly dust-free product, and due to their

reduced thermal stress.A spray drying process using a FBD is also called two-stage drying. Figure 4 shows a two-stage drying

process carried out by using a spray drier with a rotary atomizer and a separate external FBD. The outlet air is filtered by a CIP

filter, which consists of a tubular filter without cyclone.When using two-stage drying, lower residual product moisture with less

harm to product quality as well as more efficient energy utilization can be achieved. The solids leave the spray with 3-5%

residual moisture. The final drying step takes place under mild conditions with low energy usage.

a) Description of the technology:After the milk has been thickened from 11% to 50-60% dry matter in an evaporator, the condensed

milk may further be dried to 95-97% dry matter content. Spray driers or roller driers are used in milk powder processing. Although

roller driers may be found in the dairy sector and are sometimes useful for specialized products, spray driers with downstream or

integrated FBD’s have become more common. This is due to their low energy usage, primarly dust-free product, and due to their

reduced thermal stress.A spray drying process using a FBD is also called two-stage drying. Figure 4 shows a two-stage drying

process carried out by using a spray drier with a rotary atomizer and a separate external FBD. The outlet air is filtered by a CIP

filter, which consists of a tubular filter without cyclone.When using two-stage drying, lower residual product moisture with less

harm to product quality as well as more efficient energy utilization can be achieved. The solids leave the spray with 3-5%

residual moisture. The final drying step takes place under mild conditions with low energy usage.

Two-stage powder drying tower:

powdered milk drying and spray tower

The last traces of moisture are the most difficult to remove, unless high outlet drying temperatures are used to provide a

sufficient driving force. As elevated outlet drying temperatures can have a detrimental effect on powder quality, it is essential

to operate at lower outlet temperatures with dairy products. If the moisture content of the resulting powder is still too high, an

after-drying stage is incorporated after the spray dryer in a two-stage process as illustrated in figure .

sufficient driving force. As elevated outlet drying temperatures can have a detrimental effect on powder quality, it is essential

to operate at lower outlet temperatures with dairy products. If the moisture content of the resulting powder is still too high, an

after-drying stage is incorporated after the spray dryer in a two-stage process as illustrated in figure .

|

Technical parameters

|

|

|

||

|

1

|

Raw material

|

Milk or milk powder

|

||

|

2

|

Product

|

UHT milk,dairy products

|

||

|

3

|

Terminal package

|

Carton brick, plastic bag, tin,can

|

||

|

4

|

We can design it according to your special requirements.

|

|

||

The Whole Producion Line Including Below Items:

1.Milk collection system

2.Ingredients sterilization system

3.Filling &Packing system

4.CIP cleaning system

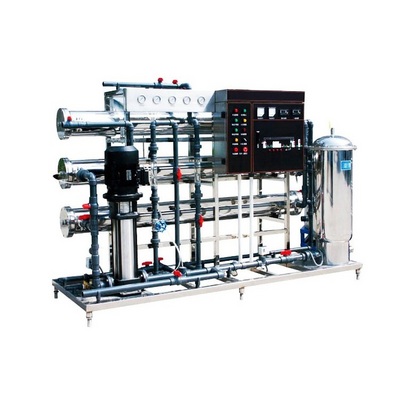

5.Water treatment system

6.Water Supply system

7.Steam System

8.Air Compressed System

9.Refrigeration Systems

2.Ingredients sterilization system

3.Filling &Packing system

4.CIP cleaning system

5.Water treatment system

6.Water Supply system

7.Steam System

8.Air Compressed System

9.Refrigeration Systems

Hot Searches