Top Plastic Machinery Manufacturer Since 1996.

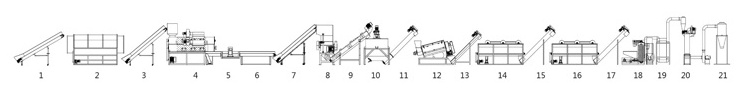

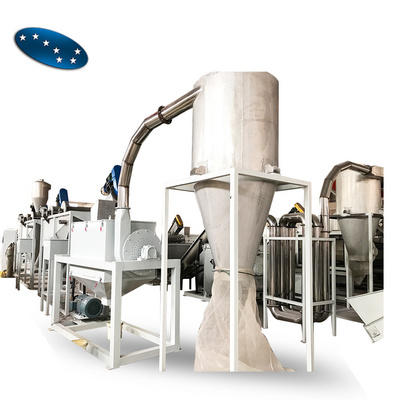

Our main products are:

plastic pipe extrusion line

and

plastic recycling machine

.

The main products are popular in the domestic market,such as the East China market,Southwest market,Northeast market and Central China market.The products are also exported to international market,including Russia,Australia, Southeast Asia,Middle East,East Europe.Africa and other countries.