NaN / 0

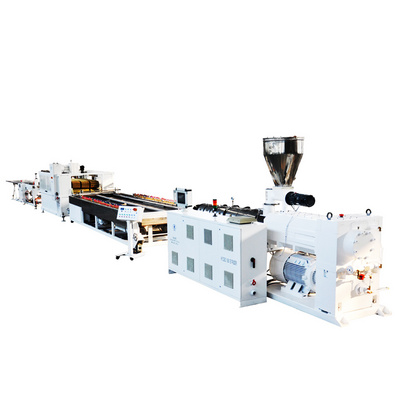

JWELL-Wood Plastic Composite WPC Products Production Machine PE/PP/PVC Recycled Plastic Material Wpc Wall Panel Extrusion Line

Get Latest Price

US$ 100000

≥1 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

132

Screw Speed (rpm):

20 rpm

Place of Origin:

Jiangsu, China

Product Details

FAQ

1. What are JWELL coming from?

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo after hundreds time of testing. Nowaday, in this location Zhoushan city, there are more than 300 companies in this reason. After more than 35 years development, JWELL is the TOP 1 extrusion machine supplier in China with 5 factories, 300 design&test engineer, 3000 employee located in Zhoushan, Shanghai, Taicang, Dongguan, Liyang.

2 . Why should I choose Jwell?

We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 500 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3000 staff Pioneer of Chinese extrusion machine supplier.

3. Are U the only JWELL in Alibaba?

Right! There are many many supplier with name Jwell in Alibaba, Plz donot be cheated by other company in the name of JWELL screw, Jwell extruder, Jwell line, etc. They're all unhonest and untrustworthy supplier!

CONTACT JWELL, CONTACT SUCCESS!

JWELL - WPC Decking Plastic Extrusion machine

WPC extrison line: It adopts special design of screw & barrel, mould and extruder for wood plastic products.Jwell company products series:One step way thick board extrusion line,One step way WPC profile extrusion line;WPC pelletizing extrusion line and different kinds of WPC mould.

The WPC products can be produced by two step extrusion machine, or pelletzing first then through extrison machine, it will save

power and place,it has some feature: high output,stable extrusion pressure,high plastication, and good mixing. Optimized screw

design have small cutting strength, and it is not easy to cut wood fibre, good plastication.

This extrusion line can produce PE,PP or PVC WPC profile products,Main application is for wood tray, indoors and outdoors

floor,and outside decoration,and so on.

Main Technical parameter:

| Extruder | Single screw | Conical twin screw | Parrallel twin screw |

| Model | JWS65/28 JWS90/28 JWS120/28 | SJZ65/132 SJZ80/156 SJZ92/188 | JWE75/44 JWE92/44 |

| Power(kw) | 30 55 90 | 37 55 110 | 75 132 |

| Max output(kg/h) | 50-60 80-100 150-200 | 120 280 500 | 300 500 |

| Center height | 1050 1050 1050 | 1050 1050 1100 | 1050 1050 |

| weight(kg) | 1200 2000 3000 | 4000 5500 8000 | 5000 8800 |

Machine List:

| Name | Quantity |

| Automatic loader | 1 set |

| SJZ51, SJZ65, SJZ80, SJZ92 conical twin screw extruder | 1 set |

| Mould and calibrating | 1 set |

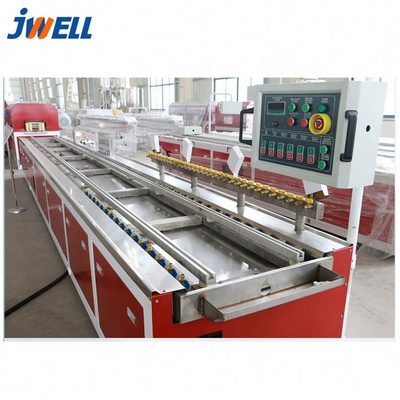

| Vacuum calibrating table | 1 set |

| Haul off machine | 1 set |

| Printer | 1 set |

| Synchro cutter | 1 set |

| Stacker | 1 set |

Production description:

WPC PVC profile extrusion line

adopts special-designed screw, barrel, and mould. Its outstanding features consist of high production efficiency, reasonable structure compact, convenient operation and maintenance and long use life. We supply

free replacement of fittings

which are damaged naturally during the warranty period.Production descrption:

Equipped with the auxiliary machinery, this plastic profile extrusion line can produce PP ,PE ,PVC, Wood-Plastic products, with the advantages of

1) Elegant nature wood grain texture and touch with wood scent

2) Elegant and detailed shape design

3) No cracking, warping and splitting

4) Water-proof and erosion-proof

5) Environmental friendly and no other hazard chemical

6) Safe to use for many years

7) Low maintenance and no painting

8) Carpenter oriented and friendly easy installation

9) Dimension stability against moisture and temperature

WPC Products

With different extruder and die, PVC WPC profile making machine can process all kinds of profiles, some of which are shown below.

Production processment:

Application:

This type of WPC (wood plastic composite) decking board can be used in outdoor ground, trestle road and garden path, enjoying great superiority in the outdoor decking of courtyard, park, garden community, waters cape, trestle and plank road.

All Key parts: screw&barrel,melt pump, screen changer, mold, and downstream equipment are made by Jwell factory!

We only choose qualified supplier

Hot Searches