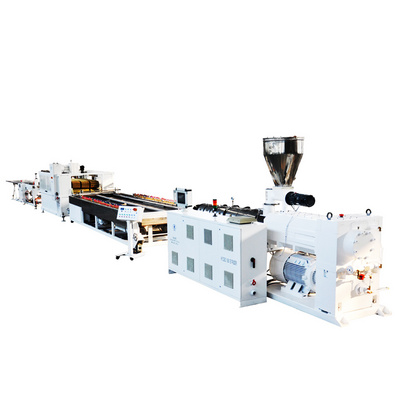

World famous brand electrical component: Siemens, Schneider, ABB etc;

High torque gearbox with adopts NSK/SKF bearing;

Siemens original motor achieved global after service;

Bimetallic screw and barrel;

Simple PID automatic temperature control system