NaN / 0

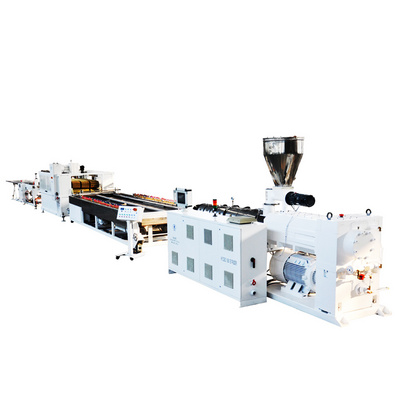

Manufacturer PVC plastic machine Wood WPC plastic composite profile extrusion making machine production line

Get Latest Price

US$ 32000

≥1 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

132:1

Screw diameter (mm):

65mm

Screw Speed (rpm):

80 rpm

Product Details

Product Overview

PVC PROFILE EXTRUSION LINE

YF series PVC profile production line suitable to produce PVC profile multi-hole cable duct(4 hole, 6 hole, 7 hole, 9 holeoption), according to different profile section and mold to choose different conical or parallel twin screw extruder and provide relative vacuum sizing tank, haul-off, cutter, stack auxiliary equipment. The capacity of main extruder is from 150kg/h to 450kg/h for option. Special design for haul-off by particular up and down technology of our company, working table stable, reliable and heavy duty force. Vacuum sizing tank having particular big eddy flow cooling system for cooling and sizing easy for cooling and sizing easy for high speed extruding necessary.

YF series PVC profile production line suitable to produce PVC profile multi-hole cable duct(4 hole, 6 hole, 7 hole, 9 holeoption), according to different profile section and mold to choose different conical or parallel twin screw extruder and provide relative vacuum sizing tank, haul-off, cutter, stack auxiliary equipment. The capacity of main extruder is from 150kg/h to 450kg/h for option. Special design for haul-off by particular up and down technology of our company, working table stable, reliable and heavy duty force. Vacuum sizing tank having particular big eddy flow cooling system for cooling and sizing easy for cooling and sizing easy for high speed extruding necessary.

PRODUCT SPECIFICATIONS

Machine List:

1. SJSZ Series Twin Screw Extruder

2. Mold

3. Vacuum Calibration Tank

4. Haul-off

5. Cutter

6. Stacker

3. Vacuum Calibration Tank

4. Haul-off

5. Cutter

6. Stacker

|

Specifications/Items

|

YF180

|

YF240

|

YF300

|

|

Max.width of board (mm)

|

180

|

240

|

300

|

|

Traction height (mm)

|

150

|

150

|

150

|

|

Traction force (KN)

|

1.8

|

2

|

3

|

|

Traction speed

|

0-5

|

0-5

|

0-5

|

|

Cooling water consume (m³/h)

|

6

|

6

|

6

|

|

Compression air (Mpa)

|

0.6

|

0.6

|

0.6

|

Detailed Images

1. SJSZ Series Twin Screw Extruder

2. Mold

3. Vacuum Calibration Tank

4. Haul-off

5. Cutter

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

6. Stracker

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Final Product

Why Choose Us?

Gegao

Service

Service Before Sale1. 24 hours online. Your inquiry will be quick reply by email. Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction,details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2.Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3.Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory. All the symbols on the equipment should be in English. Seller is responsible to provide general layout plan, electric plan,installation direction, and manual book in English to Buyer on time.

Packing&Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client’s warehouse to loading

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client’s warehouse to loading

Our Services

Company Introduction

Our company occupies an area of 20,000 square meters, and we own 7,000-square-meter international standard factory building.

Ourcompany is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, conedouble -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

Ourcompany is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, conedouble -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

Certifications

FAQ

Q:Are you machinery factory or trading company?

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days.

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days.

Hot Searches