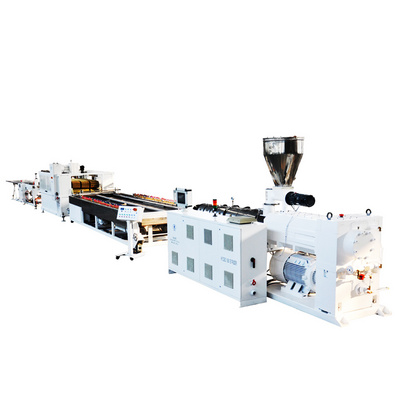

Name: SJZ65/132 Conical twin screw extruder

Technical parameters:

a.Main motor :37kw Siemens Brand.

b.Inverter:ABB

c.Screw barrel: 38CrMoAl, hardness Hv950 or more , high-efficiency and long service life.

d. Vacuum pump : Double station.