NaN / 0

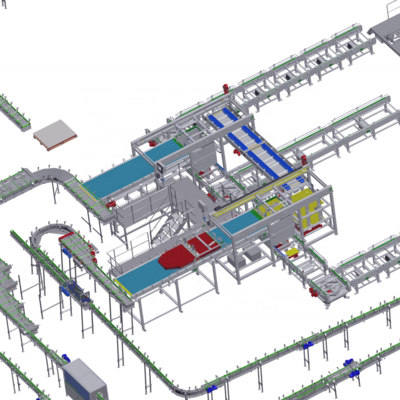

Pet Dog Food Making Production Line Canned Wet Pet Food Production Line

Get Latest Price

US$ 95000

≥1 Sets

Quick Details

Marketing Type:

New Product 2023

Place of Origin:

Shanghai, China

Brand Name:

LWT

Voltage:

380V

Product Details

Product Description

|

Product Name

|

Canned Food Production Line Tin Can Wet Pet Canned Processing Line

|

|

Application

|

Canned dog food, canned cat food, etc

|

|

Operation mode

|

Fully automatic / semi-automatic (customized)

|

|

Capacity

|

1400-6000bph(It can be customized according to the capacity)

|

|

Support bottle type

|

Glass Bottle,Iron Cans,Plastic Jar

|

|

Name

|

Model specifications

|

|

|

Pre-processing process

|

|

|

|

1. Bubble cleaning machine

|

Bubble(dry bean 0.5T--1T/H)

|

|

|

2. Precooker

|

With cooling 5min (85℃-90℃) L=10m W=1100mm

|

|

|

3. Soak

|

With lifting

|

|

|

4. Washing machine

|

Empty can

|

|

|

5. Lifting conveyor

|

moveing to tank of filling machine

|

|

|

6. Filling Machine

|

use measuring working way

|

|

|

7. Sealing Machine

|

Sealing Can(500g)

|

|

|

8. Loading Can

|

By magnetic

|

|

|

9. Unloading Can

|

By magnetic

|

|

|

10. Drying

|

By air

|

|

|

11. Labeling Machine

|

Labeling Machine

|

|

|

12. Print Machine

|

Print date(VIDEOJET)

|

|

|

Packing Line

|

|

|

|

13. filled cans washing and drying machine

|

Clean the residue on the can

|

|

|

14. Lid loading machine+Capping machine

|

Seal the jar

|

|

|

15. high pressure sterilization machine

|

Sterilize cans

|

|

|

16. drying system

|

|

|

|

17.case packer

|

Load the product into cartons

|

|

|

18.palletizer

|

Stack products together

|

|

|

17. Wet glue labeling machine

|

Labeling cans

|

|

|

18. date ink-jet printer

|

Date printing of cans

|

|

|

19. rotated turntable include motor driving conveyor

|

Used for conveying products

|

|

|

20. manually base box packing paltform

|

|

|

|

21. automatic wrapping machine

|

Wrap the packaged products together

|

|

Product Show

Other Parameters

1.Empty Bottle De-palletizer

Empty cans de-palletizer is mainly composed of lifting mechanism, moving mechanism, magnetic suction mechanism, conveyor and electrical controlling system. The working way adopts magnetic suction and moving type. It can match with magnetic lifting conveying system, can transport product in the air and can transport product among different height of floor.

2.Empty Bottle washing and drying machine

Descriptions:

The machine is used for tinplate can,ring-pull can continued cleaning,adopt steam heating way,temperature is adjustable,it adopt high pressure standard nozzle. It has good cleaning efficiency,reasonable structure,stable work performance,high efficiency,it is ideal equipment of canned food beverage production line.

Parameter

|

Name

|

Empty Cans Washing Machine

|

LW-WM100

|

|

|

Capacity

|

50-300cans/min

|

50-100 cans/min

|

|

|

Washing Section

|

1-2 Section washing

|

1 Section washing

|

|

|

can diameter

|

40-150mm

|

40-150mm

|

|

|

Power

|

1.5KW

|

1.1KW

|

|

3.Filling Machine

Filling machine is widely used in sauce, food, daily chemical and other industries. It can be filled with minced meat, chili sauce, mushroom sauce, honey, oil, fruit juice, beverage, etc. Servo control is adopted, with high measurement accuracy and stable operation.

4. Can Sealing Machine

Automatic vacuum sealing equipment, especially suitable for tin cans, aluminum cans and other bottle types. It has vacuum pumping

function and can also add nitrogen.

function and can also add nitrogen.

Simple operation and humanized design. The automatic lower cover is customized according to the size of the customer's cover, and the pneumatic lower cover system makes the work higher and more stable. The positioning conveyor belt is better connected to other production equipment and more efficient.

5.

Cleaning Machine

characteristics and uses

1, raw materials under the action of pressure and force bubbles sink was fully broken up, turn the flow, cleaning, transfer.

2, The device is an efficient cleaning ability, energy-saving, water-saving, avoiding the waste of resources to reduce production costs

3, the device has a relatively wide range of applications, mainly for: Vegetables, fruits, mushrooms, fish and other granular, leafy, root cleaning products, soaking, sterilization and fixing the like.

6.Sterilization Machine Retort

It is mainly applied to all kinds of cans of drinks, tin cans of drink, canned meat, canned vegetables and secondary sterilization plastic bottle beverage etc process loading automatically before sterilization,unloading after sterilization,replace the artificial working,save manpower, greatly improve production efficiency.The machine adopts magnetic suction to prevent the chafing and squeezing of the cans.

7.Filled Cans Washing and Drying Machine

It is applied to clean and dry outside surface of all kinds of canned fruit,canned meat,bottled sauce and all kinds of drinks.(specializedin washing and drying the adhensive sugar water and otheradhenionoutside of the sealed canned products or beverage),applying for tin cans,glass bottles and plastic bottles.

8.Labeling Machine

It Adopts enclosed transmission box,full mechanical

transmission,

adhesive attached to various round bottle labels,stable and reliable.suitable for round pot labeling.

9.Cans Palletizer/De-palletizer

Filled Cans Palletizer is suitable for palletizer and depalletizer of the filled glass bottles,filled tin cans,empty tin cans,it is main composed of conveying system and palletizing system.Working way uses magnetic grabmovement.

11. Case Packer

Carton packing machine has the characteristics of simple structure, easy to maintain.Use Siemens PLC, Danfoss transducer,Schneider low-voltage electrical appliances and the SEW motor,the machine performance is stable and reliable .

Hot Searches