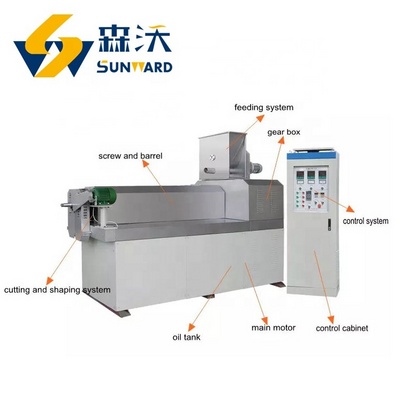

Discharge method: bottom butterfly valve discharge.

Particle fineness: less than 10mm

Production capacity: according to different model.