NaN / 0

Pet dog food extruder machine kibble dog food machine extruder production line pet food production line

Get Latest Price

US$ 25000

≥1 Sets

US$ 23000

≥3 Sets

Quick Details

Marketing Type:

New Product 2021

Place of Origin:

Shandong, China

Brand Name:

MINGDE

Voltage:

380V/Customized

Product Details

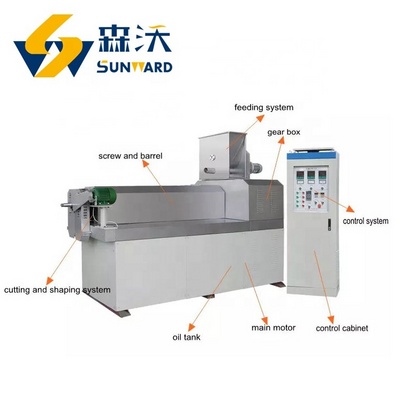

Full automatic Dog food manufacturing machine production line

The pet dog cat food machine can manufacturer the food with novel various shape, particular tastes and scientific nutrition for lovely pets. Our machines enjoy excellent sales by its high outputs and simple and easily be operated which can help you save manufacture space and manufacture cast.

Kibble dry dog cat pet food making processing machines uses uses meat meal, fish meal, corn powder, soya meal and other grains

powder as main materials to make the pet food, like dog, cat, fish, bird food etc. with different shapes and taste by changing the

dies, formulations. The pet foods are made under high temperature condition, and popular to the pet food market

|

Model

|

65

|

70

|

85

|

95

|

135

|

|

Voltage customized

|

380v/50Hz

|

380v/50Hz

|

380v/50Hz

|

380v/50Hz

|

380v/50Hz

|

|

Installed power

|

80kw

|

88kw

|

115kw

|

130kw

|

150kw

|

|

Power consumption

|

60kw

|

65kw

|

100kw

|

120kw

|

130kw

|

|

Capacity

|

120-150kg/h

|

200-300kg/h

|

400-800kg/h

|

1000-2000kg/h

|

2000-3000kg/h

|

|

Length

|

26m

|

28m

|

45m

|

45m

|

55m

|

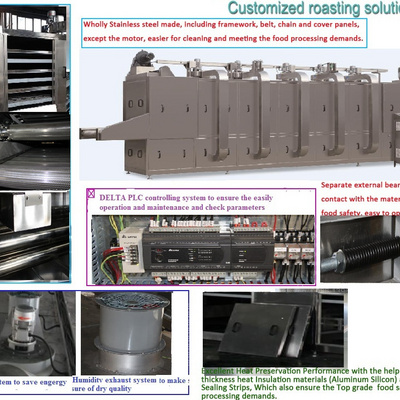

Advantage of pet food machine:

1) All pet food equipment are made of stainless steel. 2). The pet food whole line fully continuous and automatic. 3). Our company provide basic pet food formula according to your require. 4). The final pet food shapes and sizes can be various by changing the mould. 5). Supply different size mould free of charge. 6). Packing machine could be supplied to work with the pet feed production line (depending on your demand).

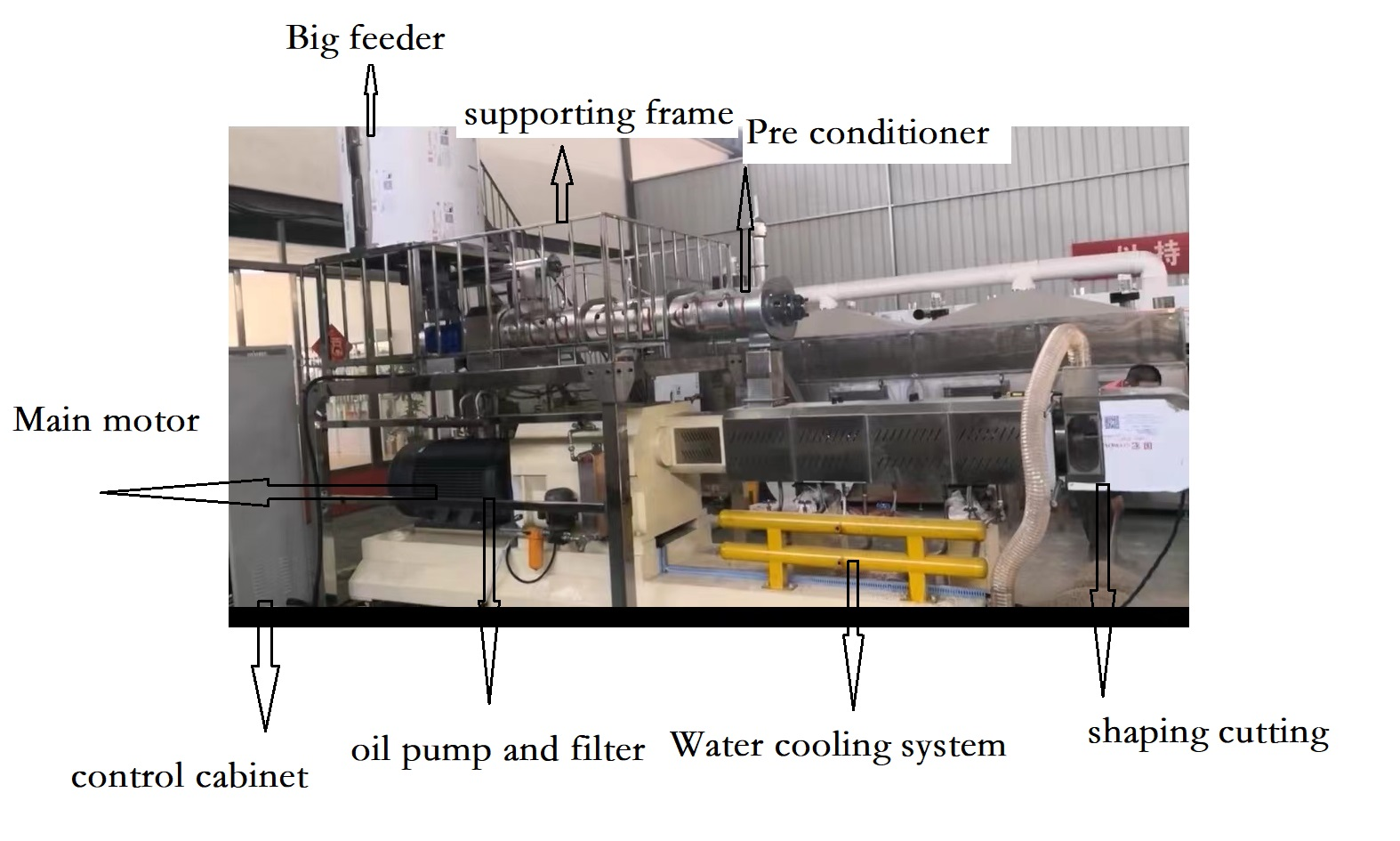

Big output extruder for producing dog food pet food etc

|

Main parts

|

Function

|

|

Pre conditoiner

|

Enables the materials stay longer in the preconditioner and evenness in the preconditioning, improves the precure degree and

increases the capacity |

|

Gearbox

|

Processed by international advanced technology ensuring machines run in long life

|

|

Twin screw

|

Segmented combined screw, suitable for a wide range of raw materials with self-cleaning system

|

|

Cutting system

|

Adopts a suspended knife assembly and linear bearing tool adjusting device to adjust the knife safely, accurately and quickly.

|

|

Lubrication and cooling system

|

Adopted refined filtration forced cooling to ensure the bearing working condition

|

|

Anti-block feeder

|

Makes sure the even feeding and stable discharge of materials

|

|

Feeding system

|

Adopts double screw forced feeding to uniformly and stable

|

Company View

Product Line

Customer and Exhibition

As a professional pet dog food production line manufacturer,Jinan MINGDE Machinery Co,.Ltd has exported to more than 80 countries

and regions, such as South Africa, Russia, Malaysia, Indonesia, Brazil and so on. Some customers become our agents in their area.

We hope to have long friendly business relationship with more customers from all over the world in the future.

and regions, such as South Africa, Russia, Malaysia, Indonesia, Brazil and so on. Some customers become our agents in their area.

We hope to have long friendly business relationship with more customers from all over the world in the future.

Recommend Products

Other products

Packing&Shipping

FAQ

1. who are we?

We are based in Shandong, China, start from 2022,sell to Domestic Market(35.00%),South America(10.00%),Africa(10.00%),Oceania(10.00%),Mid East(10.00%),Southeast Asia(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

pet food machine,snacks food machine,instant noodles machine,dog snack food machine,pellet chipsmachine

4. why should you buy from us not from other suppliers?

Has good experience, well-experienced managers, outstanding engineers as well as well-trained technical workers, established a strong technical guarantee system. We are one of the most rich experienced manufacturer of food extruder siince 1990 in China.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Russian

We are based in Shandong, China, start from 2022,sell to Domestic Market(35.00%),South America(10.00%),Africa(10.00%),Oceania(10.00%),Mid East(10.00%),Southeast Asia(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

pet food machine,snacks food machine,instant noodles machine,dog snack food machine,pellet chipsmachine

4. why should you buy from us not from other suppliers?

Has good experience, well-experienced managers, outstanding engineers as well as well-trained technical workers, established a strong technical guarantee system. We are one of the most rich experienced manufacturer of food extruder siince 1990 in China.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Russian

Hot Searches