NaN / 0

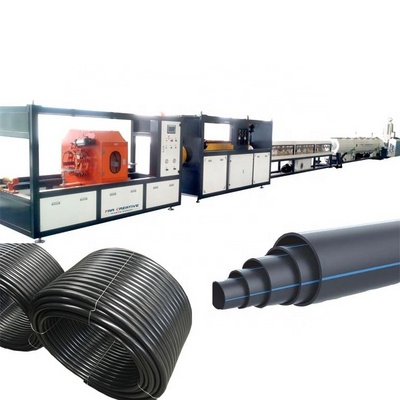

PVC Double Wall Corrugated Pipe Making Machine HDPE PE plastic corrugated pipe production line

Get Latest Price

US$ 76000

≥1 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

30:1

Screw Speed (rpm):

1500 rpm

Place of Origin:

Jiangsu, China

Product Details

Products Description

SJZ-80/156 Double Screw Extruder

Screw extruder 80:156

Heating zone 5

Screw, barrel material 38CrMoAlA

Gear box 20CrMoTi, speed ratio: 12.5/1

Screw effective length 2082

Rotate speed: 1-34.5rpm

Main electromotor power: 55KW

Main electromotor rotate speed 1500rpm

Auto feeding equipment

transducer 0.75KW

Vacuum exhaust: 1.5KW

Mandril of screw temp. controller 6KW

Output: 200kg/hr

Heating segments 5

Heating power 36kw

Center height: 1000mm

Power of cooling blower: 0.25KW*5

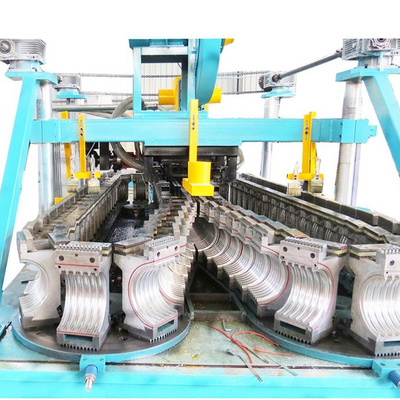

Forming Machine

Product Diameter 110mm,

160mm,

200mm

Motor 22KW

Transducer 22KW, HOLIP

Contactor SIEMENS

Cooling blower 180w/pc *4

Worm wheel gear-box 1 pc, speed ratio:100/1

Pneumatic parts Imported

Application and features:

Double wall corrguated pipe making machine adopts complicated mechanic head ,double combiated machine to production to provide material and spiral writhe .The con-stitution is nice and design is special .It can guerantee the high quality of the product.The machine is controlled by the advanced PLC computer ,easy operation and steadiness.

For HDPE,you can choose high efficient single screw extruder.

For PVC,you can choose conical twin screw extruder or parallel twin downstream equipment.

The forming system of this line consists of mould and corrugator.The mould blocks can be easily changed and they may have air or water cooling system. The belling process can also be cutting machine.The production line can also be equipment with siemens company logic control system.

Feature:

1) Adopts lastest German technology, and it is convenient to change the mould block, then it is easy the change the size of produced pipe

2) The line shallbe used to produce single wall corrugation pipe in PVC, PP and PE raw material

3) Moulding corrugated pipe with smooth inside and outside surface, and even ripple at one time by corresponding die

4) Used as wire and cable passing pipe, washing machine drain pipe, dust collector pipe and ventiduct

Product Paramenters

|

Main technical parameter

|

|

|

|

|

|

|

||||||

|

Moder Number

|

Production Specification

|

Cooling Method

|

Raw Material

|

Main Extruder

|

Output(kg/hr)

|

Power(kw)

|

||||||

|

BW-II-90/160

|

DN90-DN160

|

Water cooling, Air cooling

|

PVC

|

SJSZ65

|

350

|

37

|

||||||

|

|

|

|

PE, PP

|

SJ90

|

250

|

90

|

||||||

|

BW-II-160/250

|

DN160-DN250

|

Water cooling, Air cooling

|

PVC

|

SJSZ80

|

500

|

55

|

||||||

|

|

|

|

PE, PP

|

SJ120

|

400

|

200

|

||||||

|

BW-II-250/500

|

DN250-DN500

|

Water cooling, Air cooling

|

PVC

|

SJSZ92

|

800

|

90

|

||||||

|

|

|

|

PE, PP

|

2*SJ90

|

500

|

180

|

||||||

|

BW-II-500/800

|

DN500-DN800

|

Water cooling, Air cooling

|

PVC

|

2*SJSZ80

|

1000

|

110

|

||||||

|

|

|

|

PE, PP

|

2*SJ120

|

800

|

400

|

||||||

|

BW-II-800/1200

|

DN800-DN1200

|

Water cooling, Air cooling

|

PE, PP

|

2*SJ150

|

1200

|

600

|

||||||

Hot Searches