2) Good flexibility and strong impact resistance

3) Cold resistance and aging resistance. The connection is simple, safe and reliable.

4) Light weight and convenient construction.

5)Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life.

6) Superior drainage performance. It is hygienic and can be recycled and used.

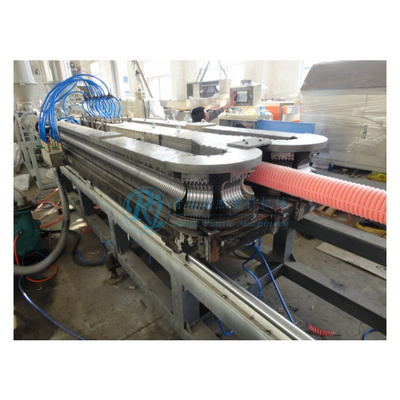

If you want to know more about Plastic Pipe Extrusion Line, inquiry us now!