The motor adopt Siemens standard motor and speed controlled by ABB inverter. The control system adopts Siemens PLC control or button control.

|

1

|

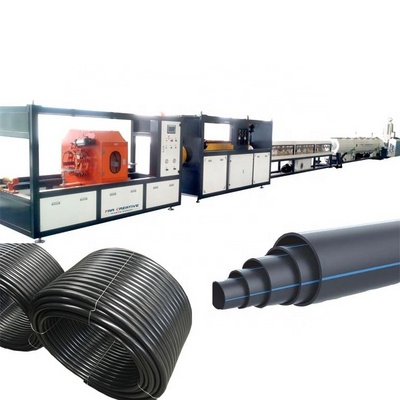

Single Srew Plastic Extruder

|

1set

|

|

2

|

Mould

|

1set

|

|

3

|

Vacuum Calibration Tank

|

1set

|

|

4

|

Cooling Spray Tank

|

1set

|

|

5

|

Hauling Machine

|

1set

|

|

6

|

Pipe Cutting Machine

|

1set

|

|

7

|

Stacker/Winder

|

1set

|

|

Specifications

|

|

|

|

|

||||

|

Machine Model

|

|

FCPL

|

|

|

||||

|

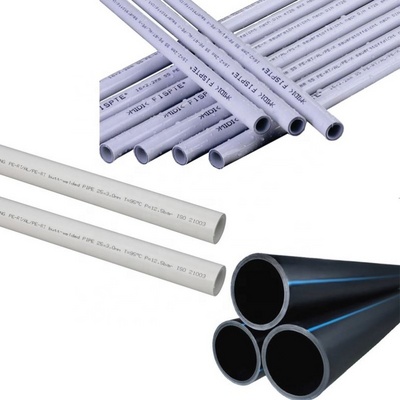

Processed Material

|

|

PVC,PE,HDPE PPR and etc.

|

|

|

||||

|

Final Product Shape

|

|

Pipe

|

|

|

||||

|

Output Range(kg/h)

|

|

120-1100

|

|

|

||||

|

Diameter of screw

|

|

50mm-130mm(standard)

|

|

|

||||

|

Voltage Standard

|

|

According to the Voltage of the Customer's Location

|

|

|

||||

|

Warranty

|

|

12 months from the date of bill of lading

|

|

|

||||

|

Technical services

|

|

Project design, factory construction, installation and recommendations, commissioning

|

|

|

||||

|

Diameter scope(mm)

|

Conical twin-screw extruder

|

Motor(KW)

|

Max.Capacity(KG/H)

|

Max. Lineal speed(m/min.)

|

|

20-63

|

SJH50/38

|

55

|

150

|

30

|

|

20-110

|

SJH60/38

|

90

|

350

|

20

|

|

40-160

|

SJH60/38

|

110

|

400

|

15

|

|

75-250

|

SJH75/38

|

132

|

500

|

12

|

|

110-315

|

SJH75/38

|

160

|

600

|

12

|

|

110-450

|

SJH90/38

|

250

|

850

|

8

|

|

315-630

|

SJH90/38

|

280

|

1050

|

4

|

|

500-800

|

SJH120/38

|

355

|

1300

|

2

|

|

700-1200

|

SJH75/38

SJH90/38

|

160/250

|

1450

|

1

|

|

1000-1600

|

SJH120/38

SJH90/38

|

355/280

|

1900

|

0.6

|