NaN / 0

Hdpe Double-Wall Corrugated Pipe Manufacturing Machine Plastic Pipe Production Line

Get Latest Price

US$ 58000

≥1 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

33:1

Screw Material:

38CrMnAl

Place of Origin:

China

Product Details

Plastic double-wall corrugated pipe production line

Doublewall corrugated pipe production line using direct extrusion process, high production efficiency, quality and reliable. Wall structure due to its excellent design, pipe lightest weight that significantly reduce the cost of the pipe, a large number of alternatives to traditional concrete pipe and cast iron pipe.

PE doublewall corrugated pipe production line machine adopts high efficiency single screw extruder, corrugated pipe outer and inner layers, respectively, two extruders independent feeding can be realized using the inner and outer layers of different colors and different materials production.

PVC double wall corrugated pipe production line machine adopts efficient twin-screw extruder.

The special structure of the composite extrusion die, the inner and outer layer of uniform thickness, shape and stability. 38CrMoAIA nitriding material used.

Siemens PLC control systems, production of full automation, reliable and stable.

Machine platform can automatically open and close, easy to operate, power may voluntarily withdraw from the die.

Strong cooling system water-cooled, air-cooled combination, can ensure high production speeds.

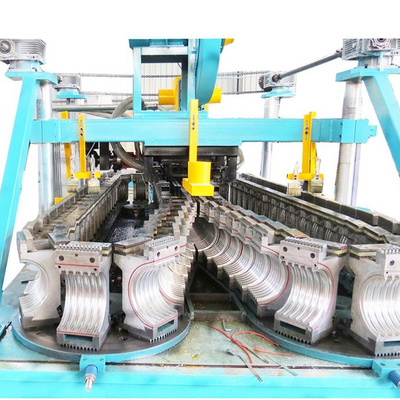

Cast aluminum alloy molding module with high precision, strength, wear resistance and excellent heat dissipation.

Belling features computer-controlled to ensure that the flaring of 1: 3, the thickness and roundness.

Technical Parameter:

|

Composition of the production line |

OD50-110mm |

OD120-200mm |

|

Main extruder |

SJ65/30 and SJ65/30 |

SJ90/30and SJ65/30 |

|

Main motor power(kw) |

37/37 |

55/37 |

|

Max output(kg/h) |

80 |

120/80 |

|

Machine die head/mould block |

50pairs/set |

50pairs/set |

|

Pipe forming machine |

BW-II |

BW-III |

|

Pipe cutting machine |

Saw blade cutter |

Planetry cutter |

|

Pipe stacking shelf |

Length 6000mm |

Length 6000mm |

|

Hopper drier |

STG-U160 |

STG-U160 |

|

Automatic feeding machine |

ZJ200 |

ZJ200 |

|

Plastic mixing machine |

SH50 |

SH100 |

|

Plastic crushing machine |

SWP360 |

SWP360 |

Hot Searches