NaN / 0

Hot Sale Clay Brick Production Gas Fire Brick Kiln Tunnel Dryer Oven for making burning bricks

Get Latest Price

US$ 700000

≥1 Sets

Quick Details

Type:

Hollow Block Making Machine

Brick Raw Material:

Clay

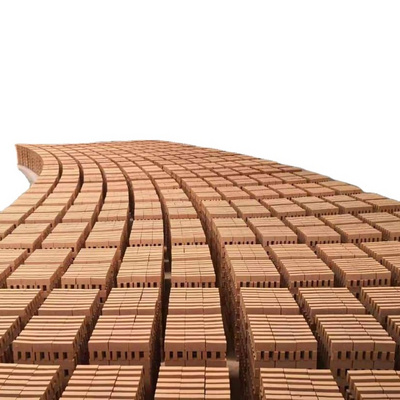

Production Capacity (Pieces/8 hours):

0~500,000 bricks per day

Brick size:

400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

Product Details

Product Description

|

Section width

|

Capacity (pcs/day)

|

|

5.6 m

|

70,000~100,000 (Standard brick )

|

|

6.8 m

|

100,000~150,000 (Standard brick )

|

|

10.8 m

|

200,000~250,000 (Standard brick )

|

|

13 m

|

300,000~350,000 (Standard brick )

|

|

15.6 m

|

500,000~600,000 (Standard brick )

|

Product Introduction

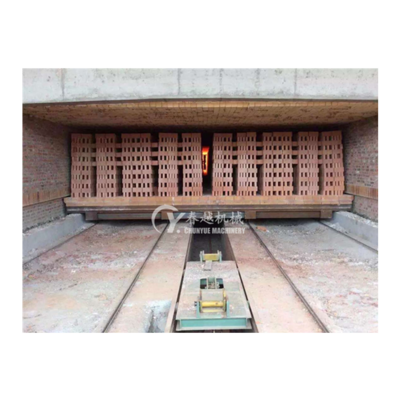

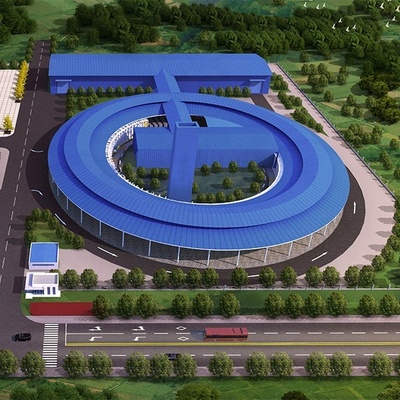

Rotary tunnel kiln is improved and upgraded from traditional tunnel kiln.

Its biggest characteristic is the adobes stay still while the body of rotary kiln moves.

Kiln body are all steel structure,the circular orbit,once upon a time,in turn, divided into the dry period, preheating section, after roasting,cooling,heat preservation paragraphs. Machine and kiln body synthetic operation,iin order to characterize code. Rotation movement of the kiln body in orbit intermittent forward, front eat bricks, back end spit finished bricks,in turn ,drying, preheating,roasting,cooling,the whole process of bricks.

Fuel:

natural gas,coal,diesel oil,etc.

Production process

Related Products

Why Choose Us

FAQ

Hot Searches