NaN / 0

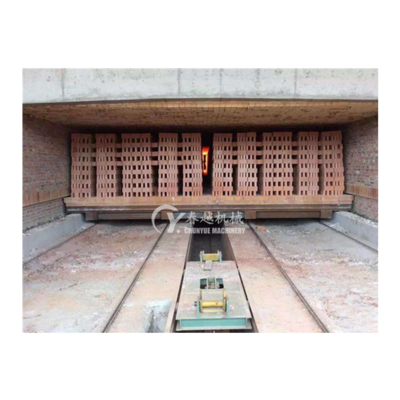

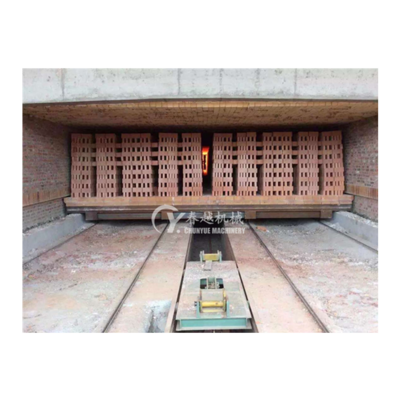

Mini Red Clay mud soil brick making machine production Burning Oven fired tunnel kiln for burning bricks

Get Latest Price

US$ 68000

≥1 Sets

US$ 50000

≥3 Sets

US$ 9800

≥6 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Solid or Hollow Brick Making Machine

Brick Raw Material:

Clay

Production Capacity (Pieces/8 hours):

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 80000---300000pcs per day

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

Product Details

Mini Red Clay mud soil brick making machine production Burning Oven fired tunnel kiln for burning bricks

What is Clay Brick Modular Tunnel Kiln?

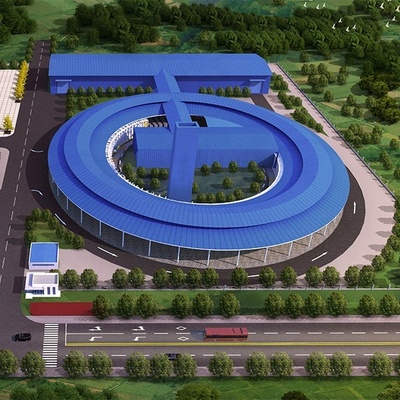

1. Tunnel Kiln Brick Plant is the most popular, fully automatic modern brick plant.

2. It consists of aging warehouse ( for processed raw materials maturing ) brick production line, dryer kiln and fired kiln.

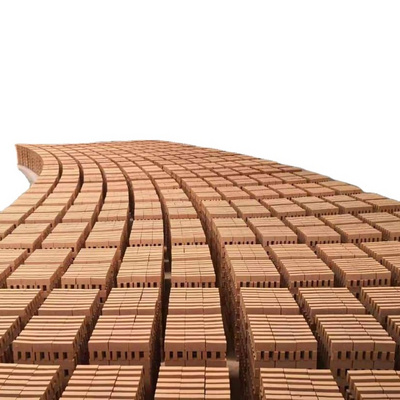

3. High Capacity. Daily output ranges from 80,000 to 300,000 pcs Chinese standard bricks (240*115*53 mm)

4. Required land (>=1.5 acres)

5. Be adaptable to both solid and hollow bricks

6. Output is not subject to weather, continuous running. (You can operate 365 days per year)

7. Heavy investment, quick investment return

1. Tunnel Kiln Brick Plant is the most popular, fully automatic modern brick plant.

2. It consists of aging warehouse ( for processed raw materials maturing ) brick production line, dryer kiln and fired kiln.

3. High Capacity. Daily output ranges from 80,000 to 300,000 pcs Chinese standard bricks (240*115*53 mm)

4. Required land (>=1.5 acres)

5. Be adaptable to both solid and hollow bricks

6. Output is not subject to weather, continuous running. (You can operate 365 days per year)

7. Heavy investment, quick investment return

Products Description

Flow chart

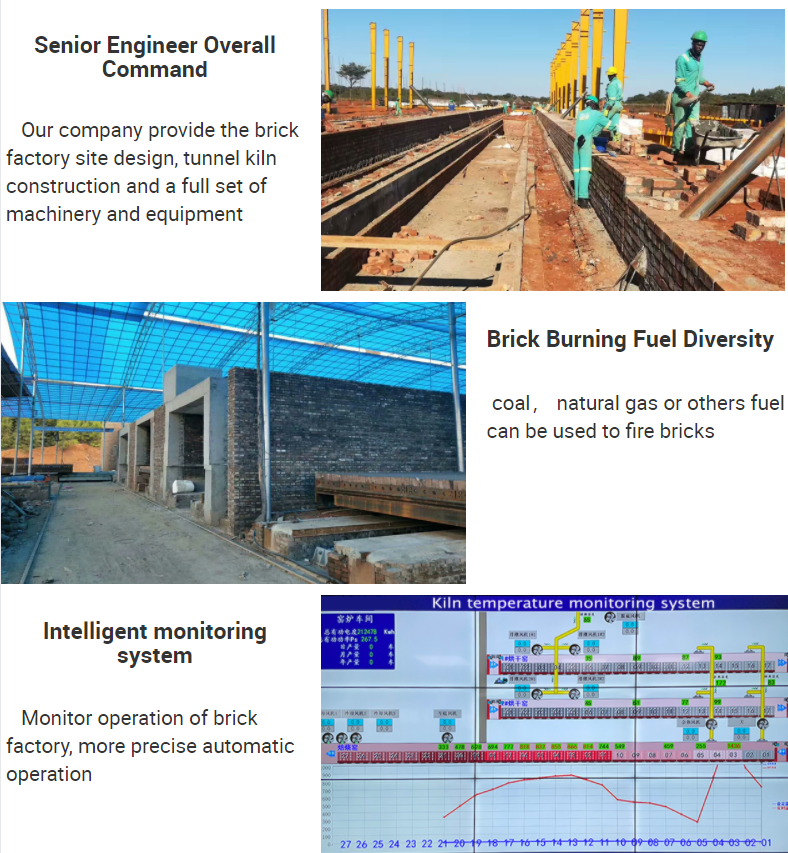

Features of Our Yuanhang Tunnel Kiln

1. Adopt "quick sintering" theory, It takes about 44 hours from wet bricks drying to final bricks. Waste hot air from firing kiln is recycled to heat wet bricks in dryer kiln. making full use of fuel. Energy saving.

2. Equipped with advanced wastes gas disposal system, achieve environmental protection standard.

3. Customize different size tunnel kiln based on your expected output.

4. Engineers are available to provide on-site service.

5. Worry-free service. Our service including

1》Free site choosing consultation

2》Free raw materials analysis

3》Layout plan

4》Supply full line brick prodcution machinery, materials needed for tunnel kiln construction and equipment in tunnel kiln

on-site engineers service

5》Machinery installation, test-run to qualified bricks

6》Provide entire working life after sales service and spare parts

1. Adopt "quick sintering" theory, It takes about 44 hours from wet bricks drying to final bricks. Waste hot air from firing kiln is recycled to heat wet bricks in dryer kiln. making full use of fuel. Energy saving.

2. Equipped with advanced wastes gas disposal system, achieve environmental protection standard.

3. Customize different size tunnel kiln based on your expected output.

4. Engineers are available to provide on-site service.

5. Worry-free service. Our service including

1》Free site choosing consultation

2》Free raw materials analysis

3》Layout plan

4》Supply full line brick prodcution machinery, materials needed for tunnel kiln construction and equipment in tunnel kiln

on-site engineers service

5》Machinery installation, test-run to qualified bricks

6》Provide entire working life after sales service and spare parts

We select the most suitable product model for you according to customer requirements, provide delivery pictures and videos, and provide customers with installation, commissioning and technical training services. Let customers rest assured to use.

FAQ

Q1: What is the warranty for this machine?

A1: 3 years excluding the easy wear parts.Spare parts is recommended to keep at least one year in case of emergency

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

Hot Searches