NaN / 0

Ce Quality Yogurt Production Plant Yogurt Processing Maker Line Milk Yogurt Ferment Machine For Dairy Production Line

Get Latest Price

US$ 18860

≥1 Sets

US$ 17680

≥2 Sets

Quick Details

Applicable Industries:

Dairy Factory

Place of Origin:

Tianjin, China

Brand Name:

Hitrees

Voltage:

110V~380V, 380V

Product Details

Product Overview

Yogurt Making Production Line/Yogurt Producing Line

The yogurt production line includes

c

ooling tank, double filter, pre-heating tank, h

omogenizer, pasteurization tank, fermentation tank, milk pump, CIP cleaning tanks.

The capacity can be customized according to your needs.

PRODUCT INTRODUCTION

Cooling Tank

The collected milk needs to be refrigerated at 4 ° C to prevent deterioration. The refrigeration tank uses the compressor to cool the milk. The equipment is made of SUS304 stainless steel. The thermal insulation layer is good for polyurethane foaming heat.

The collected milk needs to be refrigerated at 4 ° C to prevent deterioration. The refrigeration tank uses the compressor to cool the milk. The equipment is made of SUS 304 stainless steel.

Double Filter

The double filter is formed by two stainless steel filters. It has many advantages such as novel and reasonable structure, good sealing, strong circulation ability, simple operation, etc.

The application range is wide. It can be used to filter out the hair and magazines in the mil. 200 mesh is advisable.

Pre-heating Tank

Pre-heating tank is mainly for the latter pump back pressure homogeneous machine. The optimal temperature of the milk average is about 60 degrees -65 degrees. The role of the pre-heating tank is to raise the temperature of milk to 60 degrees -65 Dead, prepare for the subsequent homogeneity, so as to achieve the standardization of yogurt.

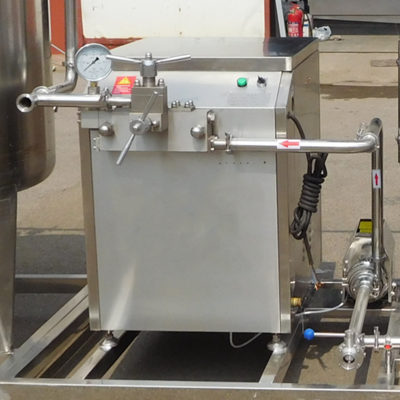

Homogenizer

Germany imported assembly septum pressure gauge, secondary gear shift; first -level leather wheels, secondary gear transmission; alloy bearing tiles, bilateral rolling bearings, stable and low noise, the average mechanical efficiency increases by about 10%. The uniform equipment has sufficient flow, stable pressure, long -term loss of parts, and the characteristics of oil -saving, low noise and other characteristics

Pasteurization Tank

The principle of pasteurization is to use the growth characteristics of bacteria. Within a certain temperature range, the lower the temperature is, the slower the bacterial reproduction is . The higher the temperature is, the faster the bacteria breeds. With the characteristic of pathogene resistance to heat. it uses appropriate temperature and insulation time to kill all of them.

Fermentation Tank

One of the important steps to make yogurt is that the fermentation temperature of the fermented yogurt is about 43 ° after fermentation, and the fatty acids in the milk can be doubled than the raw milk milk. These changes make the yogurt easier digestion and absorption, and the utilization rate of various nutrients can be improved.

CIP Cleaning Tank

The CIP cleaning system can ensure the cleaning effect, save operation time, improve work efficiency, save energy, steam and other energy; high level of automation, extend the service life of production equipment.

TECHNICAL PARAMETERS

|

No.

|

Item

|

Data

|

|

1

|

Model

|

YPL500

|

|

2

|

Capacity

|

500L / batch or customized

|

|

3

|

Power

|

20KW

|

|

4

|

Voltage

|

110V~380V

|

|

5

|

Material

|

Food grade 304 stainless steel

|

|

6

|

Customization

|

Accepted

|

PACKING AND DELIVERY

COMPANY PROFILE

Hot Searches