NaN / 0

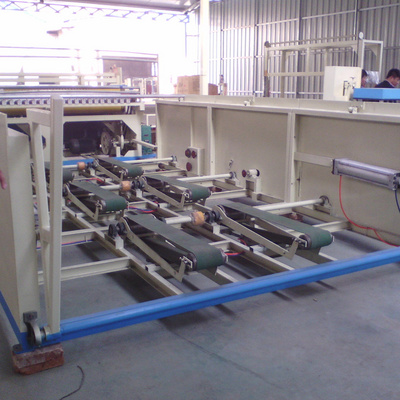

1800mm jumbo roll full automatic toilet paper embossing rewinder cutting converting machine

Get Latest Price

US$ 28800

≥1 Pieces

Quick Details

Production Capacity:

99%

Applicable Industries:

tissue paper making mill, paper converting mill, paper making mill

Place of Origin:

Shandong, China

Brand Name:

Xuridong

Product Details

1092-3200 Toilet / tissue paper converting machine

Instruction

Adopting with advanced PLC programming technology, and variable speed adjustment, electronic brake and human-machine interface operation table.

This equipment produce small raw material and towel roll. It has the function of embossment, perforation, slitting and rewinding ,all of them can be finished on one time. This machine equipped with pneumatic jumbo roll lifter , pneumatic belt driving, tension adjustment and so on. Adopt air-shaft for reeling.

Main features

1. Adopt air-shaft for reeling, convenient to set the position of paper pipe

2. press-edge system: adopt steel against steel press-edge, independence cylinder adjustment, convenient to adjust to avoid paper layer apart.

3. Horizontal type unreeling stand, pneumatic lifter , pneumatic flat belt convey paper, there is individual tension adjustment unit on each jumbo roll.

4. Adopt front and back inching switch to draw raw material, convenient for operation and safety.

5. As per requirement of customer, it can add spray sealing function. (need to order)

Scope of supply

1. rewinding machine

2. automatic volume-cutting machine or manual volume-cutting machine

3. plastic-packing machine

Model and parameters

|

1092 |

1575 |

1760 |

2200 |

2500 |

2800 |

3000 |

3200 |

||

|

Max Width of Raw Paper |

1300mm |

1800mm |

2000mm |

2200mm |

2500,mm |

2800mm |

3000mm |

3200mm |

|

|

Outer Dia. of Raw Paper |

1200mm (Other size to be specified) |

||||||||

|

unwinding stand |

1-3 Stands (The Qty. of raw paper rolls to be specified) ( To be ordered) |

||||||||

|

Inner Dia. of Raw Paper Core |

3 inches

|

||||||||

|

Data setting |

Human-machine interface(the touching screener is optional.) |

||||||||

|

Programming Controller |

PLC |

||||||||

|

Braking |

Electronic / pneumatic |

||||||||

|

Machine Speed |

180-200m/per hour |

||||||||

|

Operating Speed |

150-180m/per hour |

||||||||

|

Outer Dia. of Finished Product |

90-135 mm (Other Size to be Specified) |

||||||||

|

Dia. of Finished Product Core |

25-50m |

||||||||

|

Perforating distance |

Adjustable |

||||||||

|

Pneumatic System |

Air Compressor, minimum pressure 5kg/cm2pa(offered by customers) |

||||||||

|

Control Voltage |

regulated power DC24V(for your reference ,need order) |

||||||||

|

Main Machine Structure |

Wallboard type

|

||||||||

|

Mainframe Transmission |

Gear-box |

||||||||

|

Move Mode |

Synchronous Belt |

||||||||

|

Main Transmission |

conversion adjusting 5.5-22kw |

||||||||

01. We are a manufacturer and we have import and export rights.

02. We produce wonderful environmental protection machines and solutions, pulp and paper making machines and solutions as well as tissue paper converting machinery and solutions,

03. Our main manufacturing facility which spans nearly 30,000m2.

04 . We have achieved a total of 32 patents over the past few years.

05.

Each year the output value of our products can reach up to 150 million RMB, to domestic and overseas.

06.

We are in very close proximity to a very famous port city – Qingdao in northern China, and this location provides us with a plethora of logistics advantages, including: easy and cost effective transport by both air and sea, also.

01. Detailed installation manual and maintenance guideline are provided with the equipment.

02 . Technical training and site-commissioning are available for you.

03. Any equipment issue, we will stand by. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

01. How to buy your idea products?

A: You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

02. How to pay?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

03. What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

04. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

05. How to keep your equipment from corrosion?

A: We use the world-famous paint, like SigmaCoatings, PainBow, etc. What's more, we paint strictly according to the standard process.

06. How do you manufacture your equipment ?

A: Our machining technology includes laser/plasma cutting, automatic welding, CNC cutting and bending.

07. How to install after the equipment arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

Hot Searches