NaN / 0

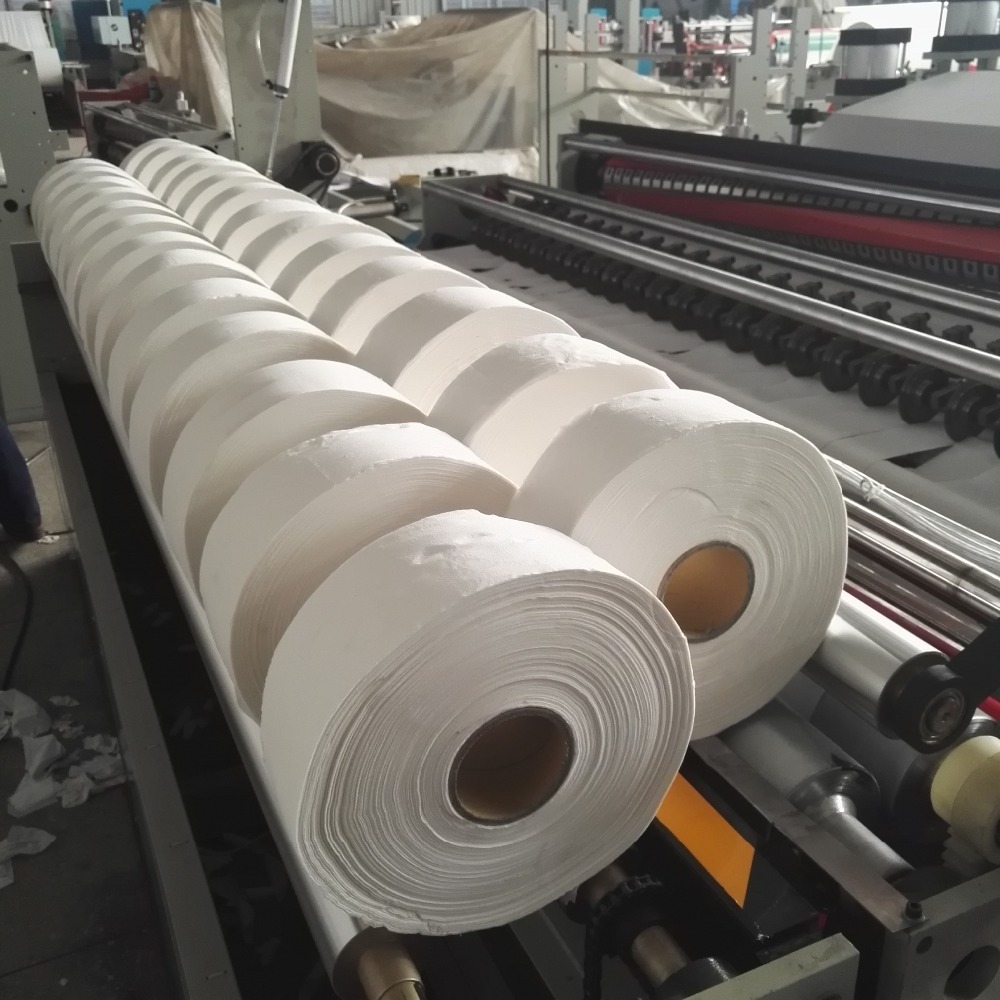

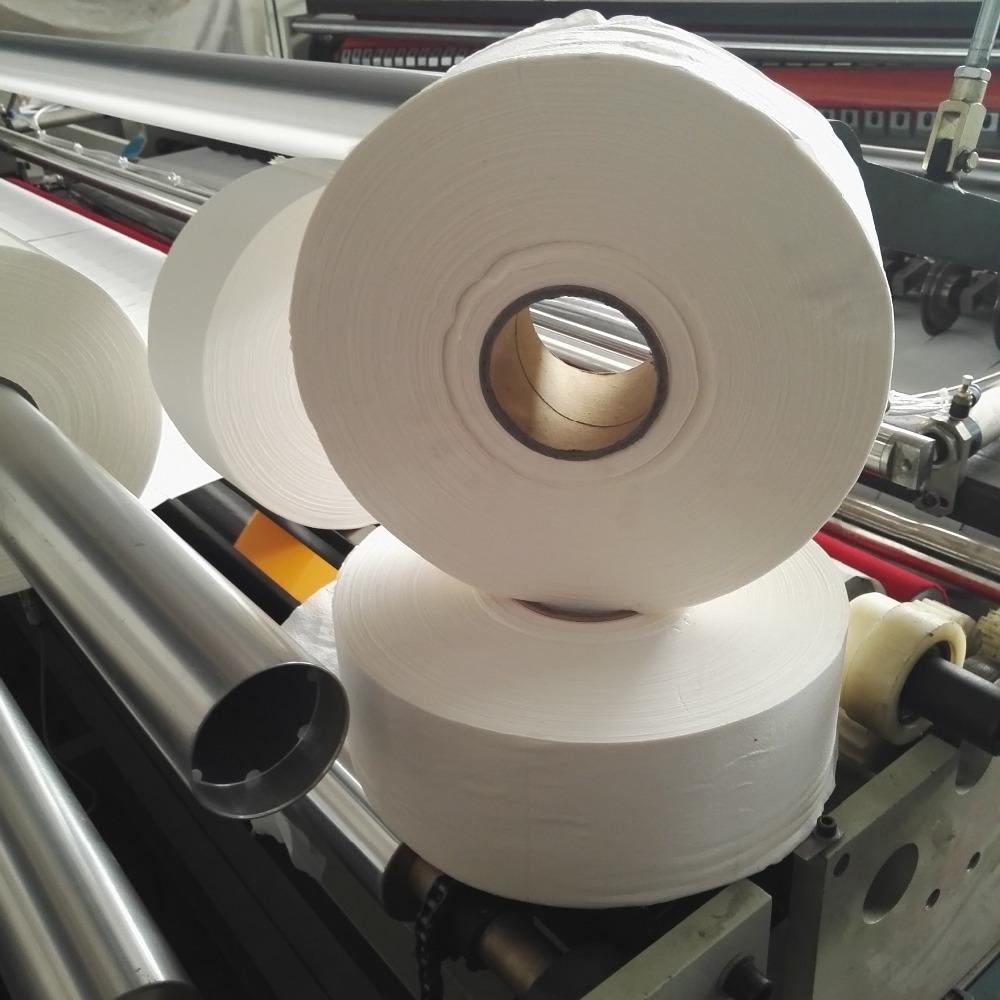

Automatic Jumbo Roll Paper Rewinding And Slitting Machine Paper Roll Cutter Slitter Rewinder Paper Roll Perforation Machine

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Type:

Slitting Rewinder

Production Capacity:

100m/min

Max. workable width:

Other

Place of Origin:

Fujian, China

Product Details

Product Description

Product Application

Automatic Jumbo Roll Paper Rewinding And Slitting Machine

Adopt advanced PLC technology, frequency control of speed adjustment, electronic braking, and touch button multi-menu type LCD screen operation control panel.

With long-distance communication service system, which can detect the machine's running at anytime, improved the production efficiency and cut down the wastage of paper.

The machine is newly added coreless roller shaped rewinding system. It adopts PLC wind pipe-shaped new technology .It's no need to put core or stainless steel pipe. It's full upgrade the whole machine.

Main Features:

1) Automatic core loading and positioning, automatic pushing out finished logs. The cores can be adjusted to any size within one minute.

2) Automatic toilet paper tail trimming, gluing and sealing: it adopts international popular trimming and sealing, which can have 10-18mm tails for easy pulling out when being used, winding must be tight at beginning and then loose towards end, to prevent loose cores after long storage time

3) Advanced PLC programmable control system.

4) Automatic detection and alarm when paper break or wrap up to guarantee the high quality of the finished

5) Coreless rewinding system has changed the traditional method to take out the core to make high quality solid coreless roller, reducing the manpower.

6) With high precision screwy perforation knife: 4 perforation blades to make clear perforating. The perforating pitch controlled by gear box.

7) Two or three back-stands, pneumatic jumbo roll loading, and pneumatically wide-belt paper unwinding, driving, and individual web tension control unit for each jumbo roll

8) The web can be threaded on the machine by two jog buttons, It's more safety and easier.

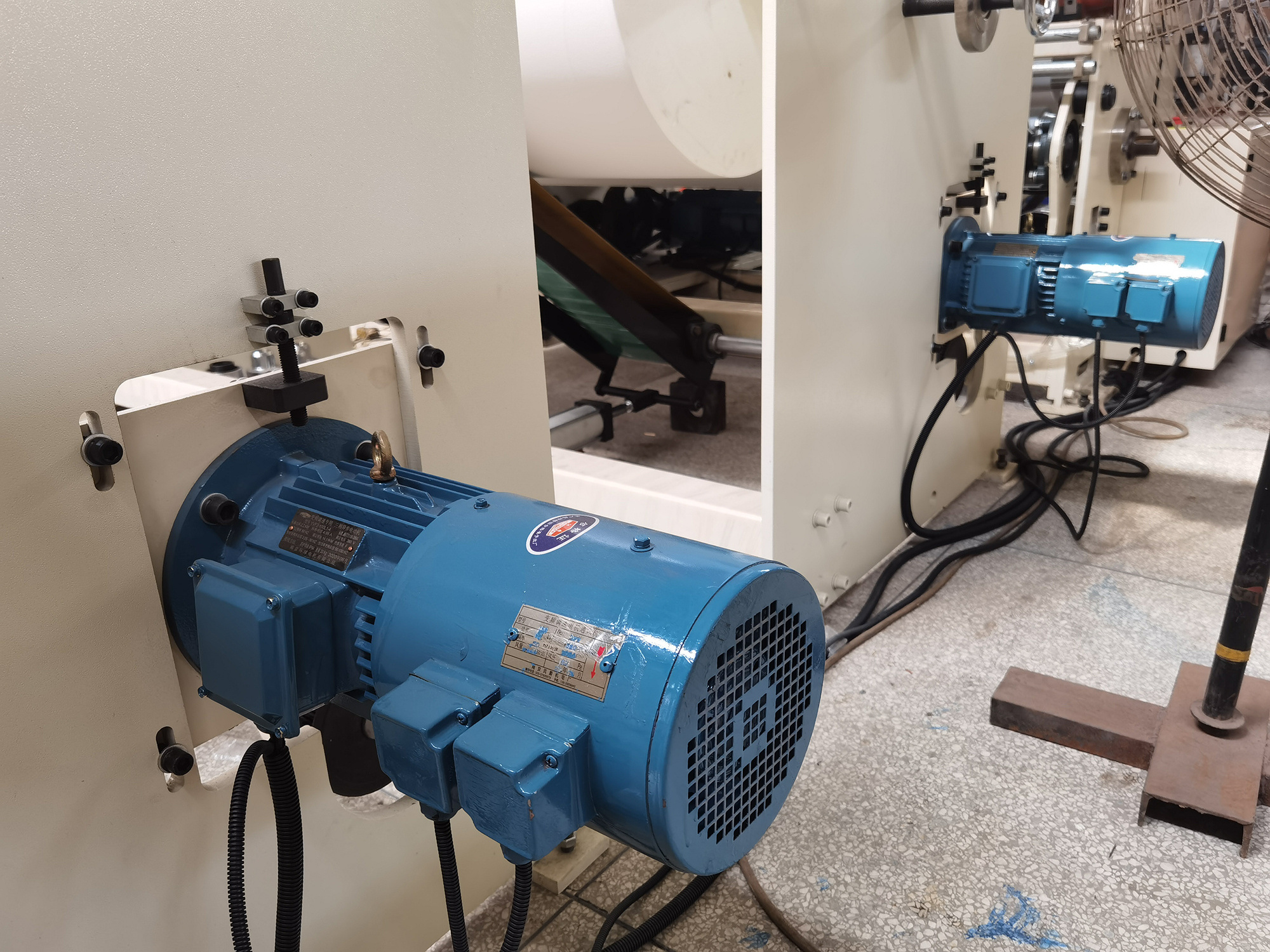

9) Motor driven by frequency inverter

10) With pneumatic lifter for perforating system and web riding roller/embossing roller, so it is convenient to adjust machine and fix out breakdown (for wide type of machine)

11) With perforating units protecting system, the paper break or breakdown happens, the perforating units will separate

automatically, so the perforating blade will not be damaged.

12) Panel type frame structure achieves stable performance. (Strong structure & and high precision)

|

Product Name

|

Automatic Jumbo Roll Paper Rewinding And Slitting Machine

|

|

|

|

|||

|

Speed

|

0-240m per min

|

|

|

|

|||

|

Max width of raw paper

|

1350/1750/2000/2400/2800 mm, other sizes to be specified

|

|

|

|

|||

|

Max width of raw paper

|

90-300 mm, other sizes to be specified

|

|

|

|

|||

|

Perforating blade

|

4 pcs spiral blades;90-120mm,180-240mm

|

|

|

|

|||

|

Embossing Units

|

single embossing, double embossing;steel to rubber,rubber to steel

|

|

|

|

|||

|

Dimension and weight

|

Dimension and weight

|

|

|

|

|||

Certifications

Packing & Delivery

|

Packaging

|

|

|

|

Size

|

3200 (L) * 2000 (W) * 1950 (H)

|

|

|

Weight

|

4.2 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Related Products

Hotsale

FAQ

Q: Why buy machine from Quanzhou Xinda Machinery Co,Ltd?

A: ① Good quality of machine with reasonable price.

② Good service: Any question from customer will be reply within 24 hours. For all the machines we sell, we will offer one-five

years guarantee for free and all life maintenance.

③ We will also send you a DVD for free. It will contribute a lots to the operation of the machine

④ After the machines arrive, the sellers shall send technician to install the production line(depends on you request)

Q: How long is your delivery time?

A: Generally it is 5-60 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

A: ① Good quality of machine with reasonable price.

② Good service: Any question from customer will be reply within 24 hours. For all the machines we sell, we will offer one-five

years guarantee for free and all life maintenance.

③ We will also send you a DVD for free. It will contribute a lots to the operation of the machine

④ After the machines arrive, the sellers shall send technician to install the production line(depends on you request)

Q: How long is your delivery time?

A: Generally it is 5-60 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Hot Searches