NaN / 0

Full automatic toilet paper converting equipment making machine

Get Latest Price

US$ 25000

≥1 Sets

Quick Details

Production Capacity:

0-180m /min

Place of Origin:

Fujian, China

Brand Name:

Xinyun

Voltage:

380v,50/60hz

Product Details

Product Description

Full automatic toilet paper converting equipment making machine

XY-TQ-B

Outline

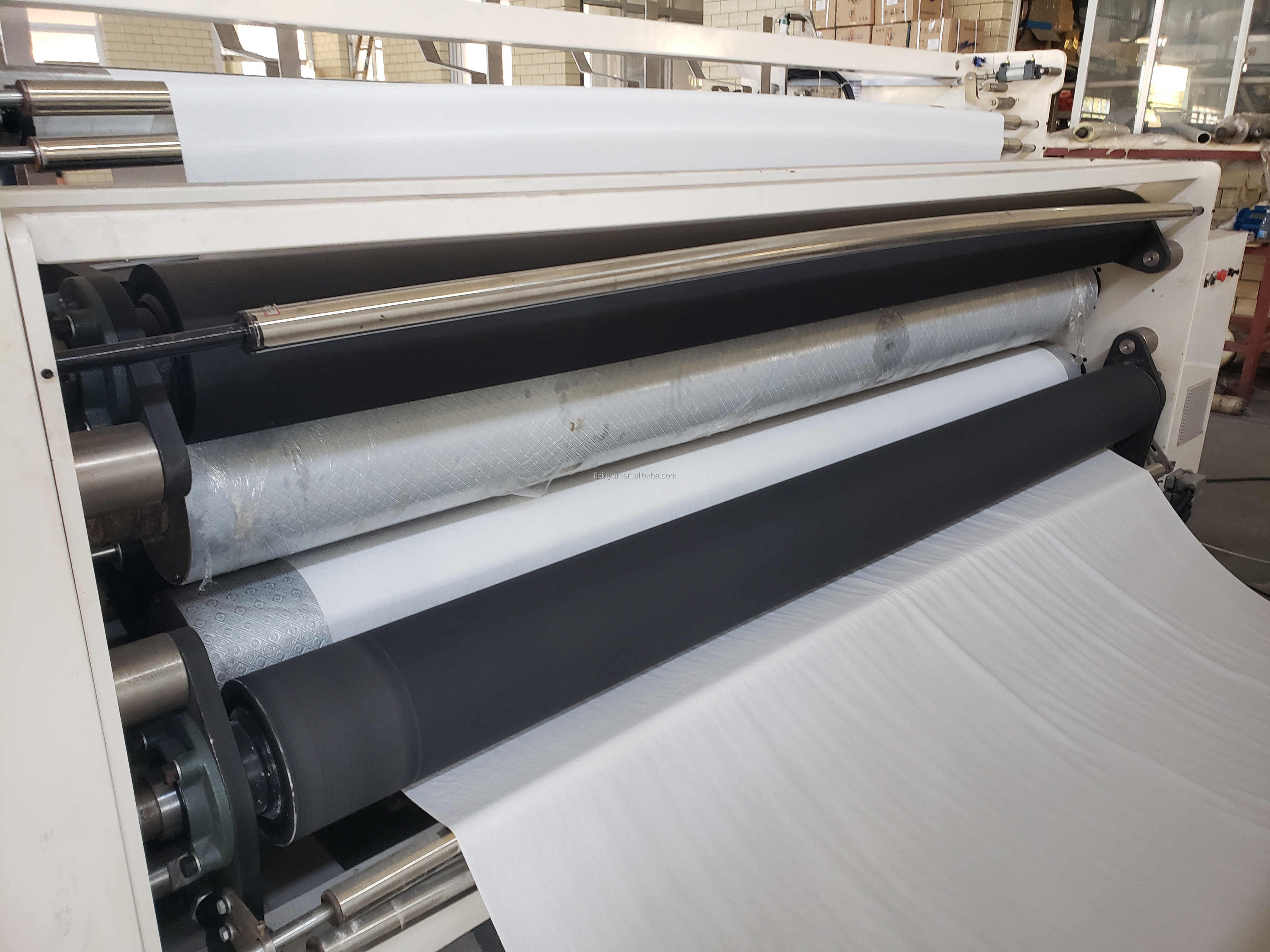

XY-TQ-B this equipment is to perforate and cut the raw paper into various sizes according to the requested. The finished product is neat, in good order and with equality tension. It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area of 8.4 m². The highest production speed is 140-200m/min. This equipment is adjustable to meet the requested finished product. This model is the ideal equipment for paper making factory and paper processing factory.

This equipment can process raw paper of 1.3m(1092B type) in width. There are two types of this model: one is ordinary type, it used one embossed unit for 2 ply paper, and the other is dot-by-dot type, it used embossed units respectally for each one.

This machine is consist of stand of raw material, paper conveying unit, embossing unit, perforating unit, rolling unit, electricity control and cutting system. The production process is : unreeling -→ embossing -→perforating-→furl-→slitting.

Function and characteristic

1.This model is designed with computer control system, fully automatic in production process, the function is complete and the production speed is high.

2.It can automatically change the core, spray the glue and seals without stopping the machine and also automatically raise and lower speed when exchanging the core.

3.When change the core, the machine will be tight first and loosen later to avoid dropping off the roll core.

4.Equipped with automatic alarm to indicate filling up of core pipe. The machine will be automatically stopped when there is no core pipes.

5.Automatic alarm for breaking off of paper.

6.Equipped separate tension control for each unwinding jumbo roll.

7.It is convenient to change the feature to produce any other core pipe winding.

8.Left paper remind after sealing of product for convenient use.

9.Jumbo roll stand is installed by pneumatic.

Technical parameter

|

Production speed

|

0-180m /min

|

|

|

Power of equipment

|

5.5kw (380v,50/60hz)

|

|

|

Maximum diameter of rewinding

|

130mm

|

|

|

Overall size(mm)

|

5800X1850X1900 (LxWxH)

|

|

|

Weight

|

About3.2T

|

|

|

Specification of raw paper

|

|

|

|

Width of raw paper

|

1000MM-1200MM

|

|

|

Diameter of raw paper

|

700mm-1200mm

|

|

|

Thickness of raw paper

|

14g/,m2-20g/ m2

|

|

|

Diameter of paper core

|

76mm

|

|

Detailed Images

Related Products

Automatic toilet paper production line

XY-AI-280

Automatic toilet paper roll cutting machine

XY-AI-398

Semi-automatic Multi rolls Packaging Machine

Packing & Delivery

FAQ

1.What can i get during I buy the paper mahine from your coropration?

first of all,we will provide best serves sincerelly to our customer ,then we'll offer the good quality paper machine with resonable prices to you

second The prices are clearly and quite good .there is no haggling as well. So you don't have to worried about you would get ripped off or anything.

2.How long dose it take freight transport to finaly destination from city ?

Reguarlly !The freight transport it would takes time about 1-60 days.

3.Is there have any engineers to instruct me to how to operate machine ?

Of cause! I'll send a professional engineer to instruct your wokers how to operate and maintain the machine in your local factory!

4.What is your terms of payment ?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Our Company

Fujian Xinyun Machinery Development Co.,Ltd

We are a Corporation What Good at

Paper Converting Machinery

Manufacture.

Professional supplier of:

1) Toilet Paper Machine

(1.2m--2.8m width of parent roll, Customize Service)

2)Kitchen Towel Paper Machine

(1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine

(2-8 output lanes)

4 )Napkin Paper machine

(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine

(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine

(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.e etc.

Hot Searches