NaN / 0

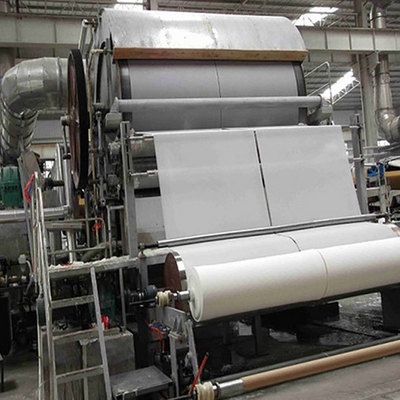

Ce Certificate Full Automatic Hemp Toilet Paper Making Machine Equipment

Get Latest Price

US$ 150000

≥1 Sets

Quick Details

Type:

paper making machine

Production Capacity:

110m/min

Max. workable width:

3300mm

Place of Origin:

Henan, China

Product Details

| 1 | Stainless steel cylinder mold | Extract the pulp fiber to felt |

| 2 | Alloy dyer cylinder | Dry the wet paper |

| 3 | Exhaust hood of dryer cylinder | To cover the dryer and collect the hot & moist air |

| 4 | Φ600 Axial-flow ventilator | To ventilate and pull out the hot & moist air in the exhaust hood |

| 5 | Roots vacuum pump | To provide the vacuum force for the suction box |

| 6 | Vacuum suction box | To absorb the water in the wet paper |

| 7 | Air compressor | To provide the compressed air for the pneumatic device |

| 8 |

Frequency conversion

controlling cabinet |

To control the running speed of the machine |

| 9 | 3m3 High concentration hydra-pulper | break the recycle paper into pulp |

| 10 | 1.8m2 High frequency vibrating screen | To separate and remove the small impurity in the pulp |

| 11 | Φ700mm impeller | To stir the pulp and make sure the pulp and water mixed well |

| 12 | 0.5m2 pressure screen (Slotted screen) | To make the pulp more finer |

| 13 | 35m3 Bleacher (include drive part) | To whiten the pulp through bleaching |

| 14 | Φ330mm pulp refiner | To make the pulp much finer and smoothe |

| 15 | Low concentration sand remover | To remove the sand and impurity in the water and pulp |

| 16 | Pulp pump | To provide the pulp for the needed machine |

| 17 | Electrical operation cabinet | To control the machines run or stop |

| 18 | 1T Boiler (burning coal ) | To provide the hot steam for the dryers |

Zhengzhou Dingchen Machinery Co., Ltd

is a professional machine manufacturer located in central China, focusing on the R&D and production of pulp and paper machines. The company has over 30 years of experience in pulp and paper machine production.

We have abundant technical forces and advanced production equipments, our goal is to ensure our customers have a good experience with our machine and service. Quality is our foundation and great service is always our mission.

Q: 1.What information do you need,if i need to get a quotation from you?

A: Output paper type;Capacity(tons/24hours);Output paper weight(gram/m2);Raw material

Q: 2.How long is the guarantee period for paper making machine?

A: 12 months after the pending operational

Q: 3.What is the delivery time if we make a order from you?

A: Usually, the delivery time for smaller machines is 30-45 days after receiving deposit,But for bigger machines, it will be longer to make sure the equipment quality.

Q: 4. What is your payment terms?

A: (1). T/T(telegraphic transfer)30% as deposit,and 70% balance paid before shipment.

(2). 30%T/T + 70%L/C at sight.

(3). 100%L/C at sight.

Q: 5.How is the quality of your equipment?

A: (1). We are manufacturer, specializing in producing all kinds of Pulping Machine & Paper,Machine & Environmental protection equipment for more than 40 years, competitive,With good quality.

(2). We have a technician team of engineers and experts.

The advanced paper making technology,to make sure our machines’ design are newest.

(3). The machines will be pre-installed at workshop before delivery.

(4). All of our machines has audited the certificate of ISO

Q: 6.Why your price is higher than other similar supplier?

A: Different quality, different price.Our price is matched with our high quality.Compared with to her supplier based on the same quality,our price is lower.But anyway,to show our sincerity, we will give you some some discount.

Q: 7.Can we visit your factory and the running machine has installed in China?

A: Welcome to visit our factory.You can check our production ability, processing ability ,check out facilities and running paper production line. What is more,you can discuss with engineers directly, and learn the machines well.

Hot Searches