NaN / 0

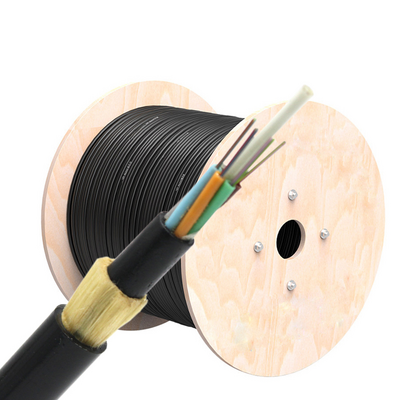

12 24 48 72 Core Adss Fiber Optic Cable Outdoor Adss Fiber Cable Span 80M 100M Fiber Optic Cable Manufacturer

Get Latest Price

US$ 0.35

≥1000 Meters

US$ 0.33

≥3000 Meters

US$ 0.29

≥21000 Meters

Quick Details

Brand Name:

Sheng Tang

Model Number:

ADSS, ADSS

Place of Origin:

Guangdong, China, Guangdong, China (Mainland)

Loose tube:

PBT

Product Details

Product Description

12 24 48 72 Core Adss Fiber Optic Cable Outdoor Adss Fiber Cable Span 80M 100M Fiber Optic Cable Manufacturer.

|

G.652 |

G.655 |

50/125μm |

62.5/125μm |

||

|

Attenuation (+20°C) |

@850nm |

|

|

≤3.0dB/km |

≤3.0dB/km |

|

@1300nm |

|

|

≤1.0 dB/km |

≤1.0dB/km |

|

|

@1310nm |

≤0.36dB/km |

≤0.4dB/km |

|

|

|

|

@1550nm |

≤0.22dB/km |

≤0.23dB/km |

|

|

|

|

Bandwidth (Class A) |

@850nm |

|

|

≥500MHz/km |

≥200MHz/km |

|

@1300nm |

|

|

≥1000MHz/km |

≥600MHz/km |

|

|

Numerical Aperture |

|

|

0.2±0.015NA |

0.275±0.015NA |

|

|

Cable Cut-off Wavelength λcc |

≤1260nm |

≤1480nm |

|

|

|

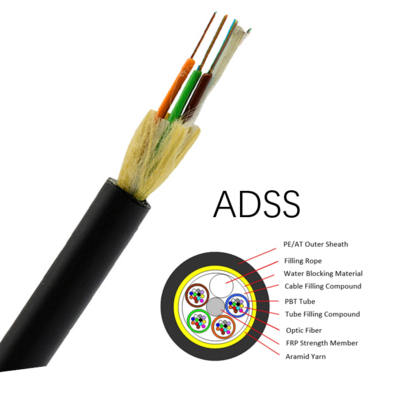

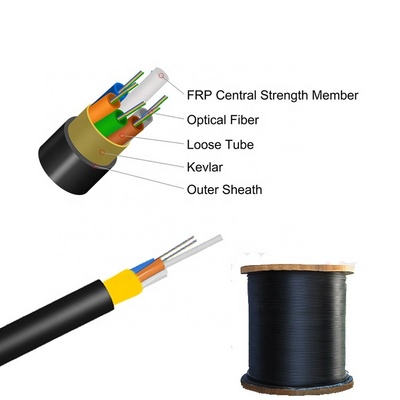

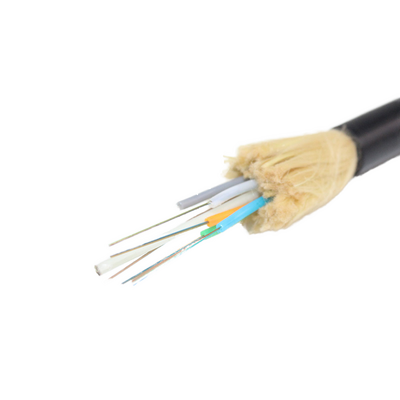

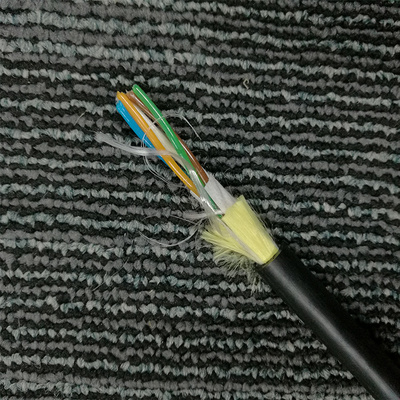

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core.

After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

Characteristics

1. Large span lengths and the largest span is over 1700 m.

2. Non-metallic material, with high insulating property performances as well as lightning-proof.

3. Special anti-track outer sheath protection, strong anti-electro-corrosion ability.

4. The aramid yarn ensure the cable's tensile resistance, and also have good bullet-proof performance.

5. Light weight with small diameter, reducing the load caused by ice and wind as well as the load on the

tower.

6. Can be installed without shutting off the power.