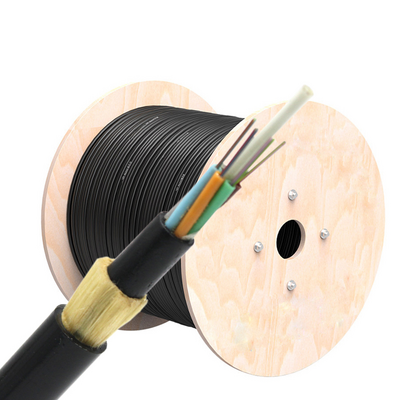

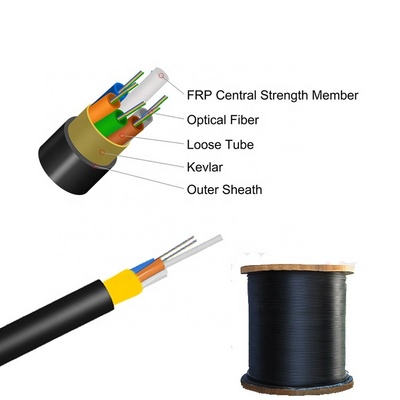

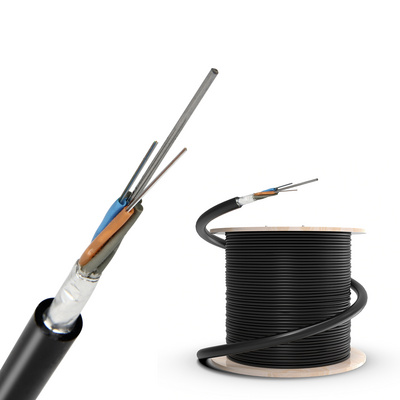

Fibers,250μm,are positioned into a loose tube made of high modulus plastics.

The tubes are filled with a water-resistant filling compound.

The tubes(and fillers) are stranded around a FRP(Fiber Reinforced Plastic) as a

non-metallic central strength member into a compact and circular cable core.

non-metallic central strength member into a compact and circular cable core.

After the cable core is filled with filling

compound,it is covered with thin PE(polyethylene)inner sheath.

compound,it is covered with thin PE(polyethylene)inner sheath.

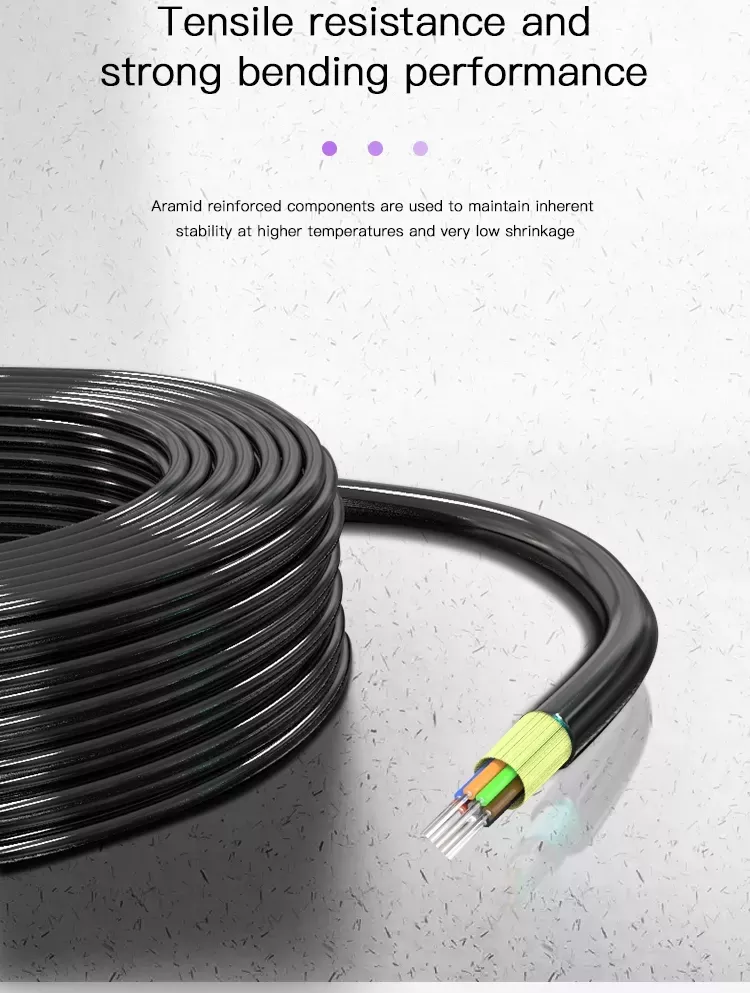

After stranded layer of aramid yarns are applied over the inner sheath as strength member,the cable is completed with PE or AT(anti-tracking)outer sheath.