NaN / 0

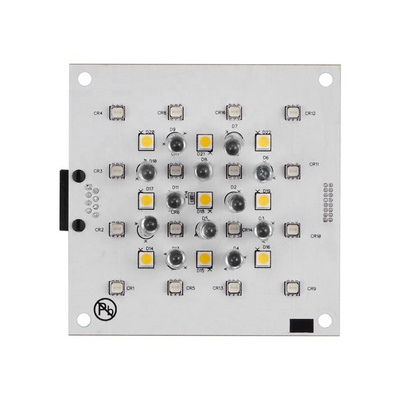

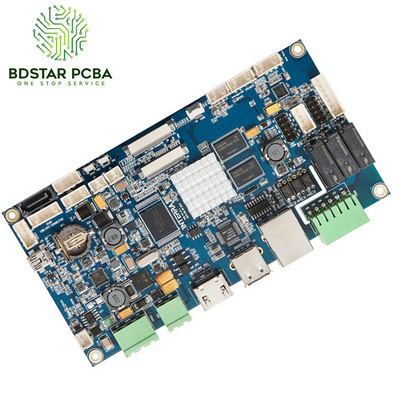

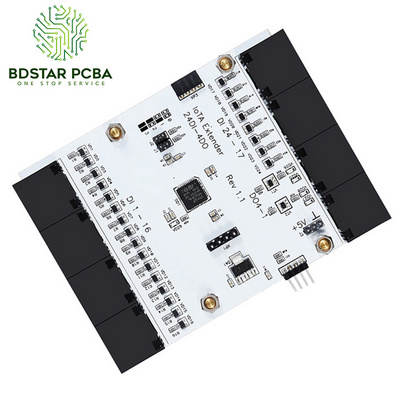

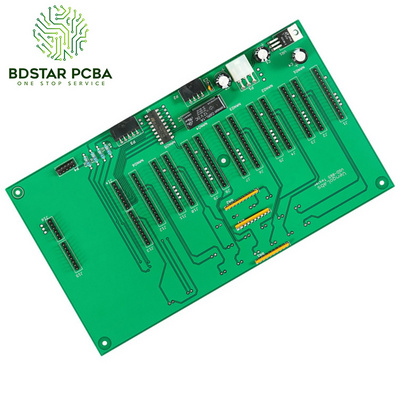

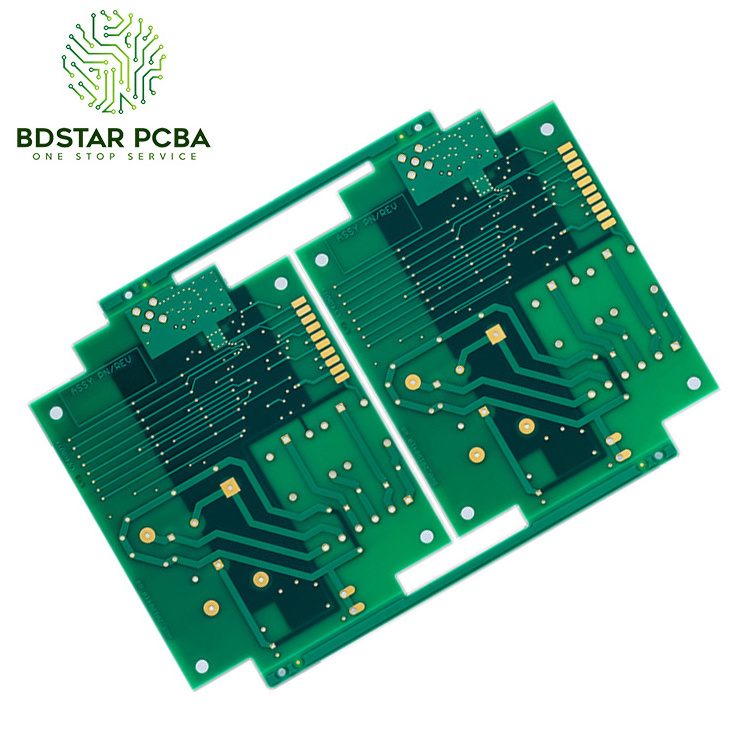

Led PCB 94v0 Multilayer Circuit Board PCBA Manufacturer Fr4/aluminium PCB Factory For Smd Led

Get Latest Price

US$ 5

≥500 Pieces

US$ 1

≥1000 Pieces

Quick Details

Base Material:

FR4 /aluminum/ceramic CEM

Board Thickness:

0.2~6mm

Board Size:

Customized color and size, Max 1200mm

Model Number:

BDX-PCB-168

Product Details

product details

capability

|

Specification of PCB Manufacturing

|

|

|

|

Layer

|

1~32 Layers

|

|

|

Material

|

FR4,CEM1,CEM3,Hight TG,Rogers,F4B,Taconic,FR1,FR2,94v0,Aluuminum

|

|

|

Order Quanyity

|

1~500,000

|

|

|

Board shape

|

Rectangular,Round,Slots,Cutouts,Complex,Irregular

|

|

|

Board Cutting

|

Shear,V-score,Tab-routed,Counter sunk

|

|

|

Board thickness

|

0.2~8.0mm,Flex0.01~0.25“

|

|

|

Copper weight

|

0.5oZ~12oZ

|

|

|

Solder mask

|

Double-sided green LPI,Also support red,white,yellow,blue,black,purple,etc

|

|

|

Silk screen

|

Double-sided or single-sided in white,yellow,red,black,or negative

|

|

|

Min line width/space

|

0.06/0.06mm

|

|

|

Max board dimensions

|

25.6 inch*43.3 inch or 650mm*1100mm

|

|

|

Min drill hole diameter

|

0.1mm

|

|

|

Surface finish

|

HASL,ENIG,Immission Ti,Immisson Silver,OSp,ENEPIG,etc

|

|

|

Board thickness tolerance

|

±10%

|

|

|

Minimal slot width

|

0.12",3.0mm,or 120 mils

|

|

|

V-score depth

|

20~25% of board thickness

|

|

|

PTH Wall Thinckness

|

>0.025mm

|

|

|

PTH Hole Dia Tolerance

|

±0.076mm

|

|

|

Non PTH Hole Dia Tolerance

|

±0.05mm

|

|

|

Hole Position Deviation

|

±0.076mm

|

|

|

Sink holes

|

Yes

|

|

|

Quality Standard

|

IPC-A600F/MIL-STD-1050D

|

|

|

Design file format

|

Ki-CAD,Pro-E Gerber RS-274X,274D,Eagle and AutoCAD'S DXF,DWG

|

|

|

Specification of PCB Assembly Manufacturing

|

|

|

|

Assembly Options

|

Surface Mount ( SMT ) . Thru-Hole ( THT ) . Box building , COB , Conformal Coating , Potting and Encapsulations , IC Programming &

|

|

|

|

Marking Gringing & Lettering

|

|

|

Types of Solder

|

Leaded and Lead-free (RoHS Compliant ) PCB assembly services

|

|

|

Stencils

|

Laser cut stainless steel stencils

|

|

|

Minimum Order

|

1 pieces

|

|

|

Component Size

|

Passive Component : we can accept components as small as 01005 . 0201 BGA : we have the ability to handle BGA of 0 . 25mm pitch

|

|

|

|

with X-ray testing Fine Pitch Parts : we can assemble 0 . 25mm fine pitch parts . POP ( Package on Package ) . QFP CCGA , CSP etc

|

|

|

|

Max Component Height : 25mm ( SMT ), Top 120mm / Bot 15mm ( Wave-Solder )

|

|

|

Component Package

|

We accept parts in Reels , Cut Tape , Tube &Tray , Loose Parts and Bulk

|

|

|

Board Dimension

|

Min Board Size : No LimitedMax Board Size : 680x500mm

|

|

|

Board Shape

|

We can assemble boards in Rectangular, Circular and any Odd Shapes

|

|

|

Board Type

|

Rigid PCB . Flexible PCB,Rigid-flex PCB, Metal PCB

|

|

|

Repair& Rework

|

Repair and rework accepted , Our BGA reballing service with which we can safely remove the misplaced BGA , reball it and put it

|

|

|

|

back on the PCB correctly . It is cost-effective

|

|

|

Testing

|

ICT . AOI , X-Ray , Function Test ( FCT ) , Aging Test

|

|

|

OutPut

|

12 SMT lines and 5 DIP lines

|

|

|

Quality Standard

|

IPC-A-610E , IS0 13485 : 2003 , ISO 16949 : 2011 , ISO 14001 : 2004

|

|

Related Products

Production

|

PCB

|

|

|

|

|||

|

layer

|

Prototype

|

|

Mass productions

(above 30 m

2

)

|

|||

|

|

quick turn

|

unual time

|

(above 30 m2 )

|

|||

|

2

|

12

hours

|

3-4 days

|

8-10 days

|

|||

|

4

|

24

hours

|

5-6 days

|

10-12 days

|

|||

|

6

|

48

hours

|

6-8 days

|

12-14 days

|

|||

|

8

|

72

hours

|

8-10 days

|

14-16 days

|

|||

|

.....

|

.....

|

.....

|

.....

|

|||

|

PCB Assembly

|

|

|

||

|

Order Conditions

|

The fastest Delivery Date

|

Standard Delivery Date

|

||

|

Prototype (<20 pcs)

|

8

hours

|

2 days

|

||

|

Small Volum (20-100 pcs)

|

12

hours

|

3 days

|

||

|

Medium Volum(100-1000 pcs)

|

24

hours

|

6 days

|

||

|

Mass productions (>1000 pcs)

|

Depends on BOM

|

Depends on BOM

|

||

Service Guarantee

QUALITY

If everything in a product is "as good as possible", the product will surely cost more than most customers are willing to pay. The end customer for example, will hardly pay more for a utility meter, just because it has a 10" color display, or because the cabinet is made of brushed aluminum. In other words, the good quality is all about fulfillment of the end customers expectations.

Therefore at the beginning of a project, it is important to realize what the function of the product should be and how it should look to best meet the end customer's needs and expectations. "Nice-to-have" features should only be included as long as the project owner is convinced that the price premium can be justified.

Success is not about having the best product possible, but about having the one that best suits the market. Unnecessary features, whether they are technical or aesthetic will only eat margins and competitiveness.

RELIABILITY

Reliability is the ability to maintain the good quality, meaning that the product continues to function properly throughout its expected lifetime. Larger companies may sometimes choose to expose new products to long-term life tests, but usually there is neither time nor money for such tests in SMEs. The cheapest method is to design for good reliability by ensuring that all components "feel good". Components that are too hot, or otherwise work near or beyond their specifications, will sooner or later cause failures. Also, you can not buy your way to good reliability by buying more expensive or more sophisticated components - on the contrary - standard components made by the millions each day are more thoroughly specified and characterized. Therefore good reliability is best secured by making a proper design work based on good knowledge of components and sensible derating of critical parameters.