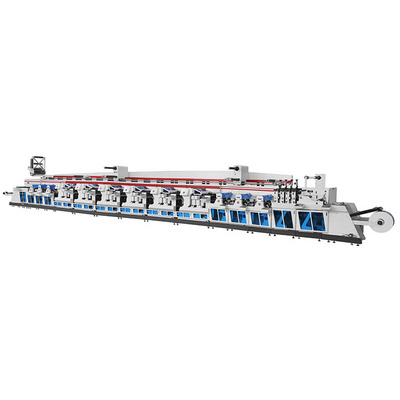

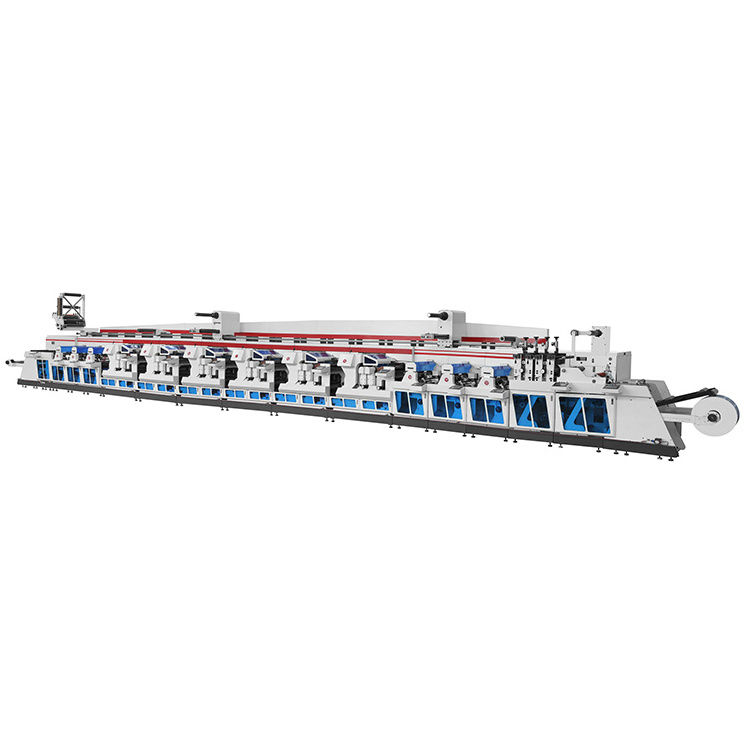

this machine must be equipped with independent equipment for each function.

Multi-color offset printing machine has the advantages of multi-functional combination, which can print on the same equipment-cold

foil-glazing-die cutting-screen-embossing, providing customers with productivity while reducing labor costs and equipment costs.

As a new generation of high-performance printing presses, multi-color offset presses provide customers with more options for

process improvement.

![[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin](https://cdn.bestsuppliers.com/seo_products_img/jeta/97fae82b5a84391f8aed4ee0c1eeea57.jpg!/rotate/180/sq/400)