NaN / 0

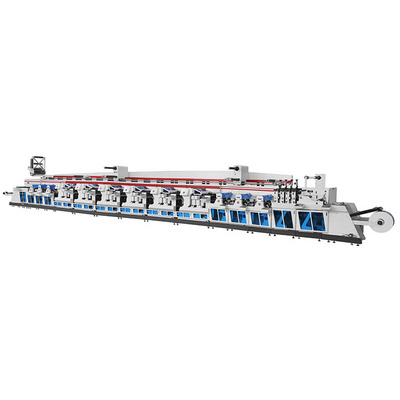

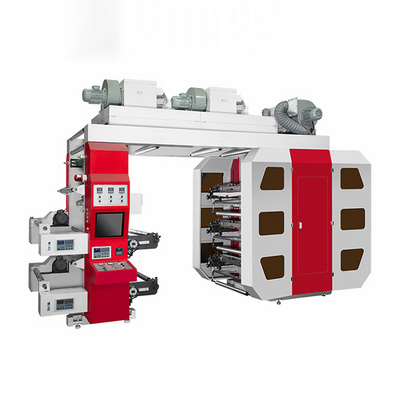

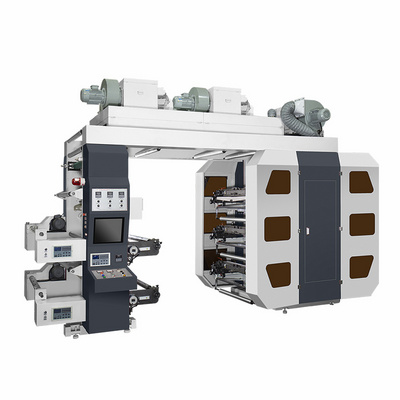

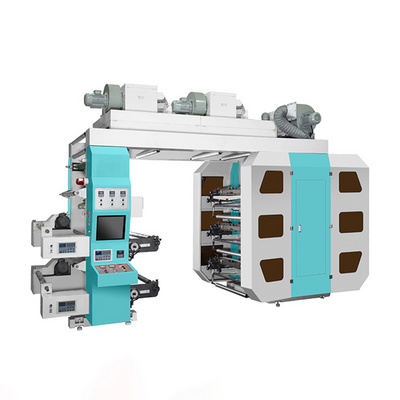

[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin

Get Latest Price

US$ 34000

≥1 Sets

US$ 33900

≥2 Sets

US$ 33800

≥5 Sets

US$ 33650

≥10 Sets

Quick Details

Place of Origin:

Zhejiang, China

Brand Name:

Jeta

Voltage:

380v

Dimensions(L*W*H):

5.5m*1.5m*2.8m

Product Details

![[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin](https://cdn.bestsuppliers.com/seo_products_img/jeta/57b23215365e3172af11f25c8e7a8654.jpg!/rotate/180)

![[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin](https://cdn.bestsuppliers.com/seo_products_img/jeta/c1bac8b610c33ad3ac32b6d98df97dea.jpg!/rotate/180)

Application:

* Automatic tension control system with magnetic brake(10KG).

[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin

for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Features:

Feedi

ng material part:

*

Single unwinder with pneumatic loading&unloading system

* Automatic stop machine when break the material; When machine stop, keep tension and avoid the material loose or line

deflection.

*

EPC (edge position control): With manually/automatically/ central return function, can adjust the rewind move left and right .

* Automatic stop machine when break the material; When machine stop, keep tension and avoid the material loose or line

deflection.

* Automatic tension control system with magnetic brake(10KG).

Printing sections:

*

The printing cylinder chromplate for avoid rusting

* Each printing unit have a ink trap , each trap have a ink pump for sucking the ink and cycle the ink between the trap and the container

* Once the machine stop , the rubber roller always working and running the ink ,Prevent ink from becoming dry and influence the print results

* Each printing unit have a ink trap , each trap have a ink pump for sucking the ink and cycle the ink between the trap and the container

* Once the machine stop , the rubber roller always working and running the ink ,Prevent ink from becoming dry and influence the print results

*

hydraulic system plate for lift and down the printing cylinder automatically .

Drying system:

* The machine is equipped with blower and heater; and the heater employed central temperature control system

* The machine is equipped with blower and heater; and the heater employed central temperature control system

*

Dry apparatus between each color, and one more dry apparatus after printing finished

*

Single rewinder system, friction roller rewinding system special for papers.

* Hydraulic loading&unloading system for the original material .

* Hydraulic loading&unloading system for the original material .

*

Edge position correct system before the material being printed .Prevent material from running sideways

* Auto tension contral system for unwind and make the mateial Prevent material from tightening to affect printing effect.

* Auto tension contral system for unwind and make the mateial Prevent material from tightening to affect printing effect.

Frame and web running:

*

The frame is made of alloy cast iron with high strength and lower stress. It is casted by resin sand process and treated by vibration aging.

* Integral type guide roller structure.

![[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin](https://cdn.bestsuppliers.com/seo_products_img/jeta/d39304ced74c35a498da51b743b01a99.jpg!/rotate/180)

|

Model

|

YTB-41000

|

|

Material feeding width

|

1000mm

|

|

Max Printing Width

|

960mm

|

|

Structure type

|

Stack type

|

|

Material

|

Non-woven fabric, Paper, Film(PVC.PE.BOPP.PE), Aluminum foil,PP woven

|

|

Thickness of plate

|

1.14mm.2.28mm,1.7MM,2.84MM,3.94MM (customized by client)

|

|

Printing length

|

280-1000mm (customized by client)

|

|

Printing speed

|

80-100m/min

|

|

Register precision

|

±0.3mm

|

|

Transmission drive type

|

Synchronous belt

|

|

Gear module

|

1.25

|

|

Machine frame thickness

|

75

|

|

Machine frame material

|

Ally casting iron and resin sand

|

|

Machine double side printed

|

2+2,1+3,4+0

|

|

SUITABLE MATERIAL

|

|

|

|

|

||||

|

Kraft paper

|

40-350g/㎡

|

|

woven

|

15-120g/㎡

|

||||

|

Single-sided coated paper

|

30-350g/㎡

|

|

Weave fabric

|

15-500g/㎡

|

||||

|

Copy paper

|

15-350g/㎡

|

|

PP woven

|

30-350g/㎡

|

||||

|

Firecrackers and paper

|

40-350g/㎡

|

|

|

|

||||

|

Paper money and incense

|

25-350g/㎡

|

|

PVC

|

10-120g/㎡

|

||||

|

Silicone paper

|

50-350g/㎡

|

|

OPP

|

10-120g/㎡

|

||||

|

Coated paper

|

30-350g/㎡

|

|

PE

|

10-120g/㎡

|

||||

|

Dust-free paper

|

25-350g/㎡

|

|

PET

|

10-120g/㎡

|

||||

|

Release paper

|

40-350g/㎡

|

|

CPP

|

10-120g/㎡

|

||||

|

Composite paper

|

30-350g/㎡

|

|

|

|

||||

![[JT-YTB41000]CE Certificate Web Flexo Printing Machine Flexo Printing Machine Ci Type Flexo Printing Machine for Napkin](https://cdn.bestsuppliers.com/seo_products_img/jeta/ee60ba83c233335eab394feff99a4e23.jpg!/rotate/180)

Hot Searches