NaN / 0

5.5-37kw Coal Sludge Sand Drying Sawdust Rotary Drum Dryer

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Type:

Rotary Drying Equipment

Place of Origin:

Henan, China

Brand Name:

Hongji

Voltage:

220 V /380 V or customized

Product Details

sawdust/ cassava chips/sand/silica sand/wood chips rotary drum dryer

Product Description

| INTRUDUCTION FOR ROTARY DRYER | |

| Brief Introduction |

Rotary dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also can be indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃). |

|

Applications |

Powder & particle:

Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.

Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc. Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc. Biomass material: Sawdust, wood chips etc. |

|

Features |

1.International standard with ISO, CE certificate. |

|

2.Simple system, safe and easy operation. |

|

|

3.Flexibility in fuels used (NG, Oil, Coal ect.). |

|

|

4.Year of experience with all types of dryers. |

|

|

5.Capable of installation anywhere in world. |

|

|

6.In house engineering for custom fit applications. |

|

|

7.Proven design. |

|

Detailed Images

|

Point 1-Steel Plate Selection

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness < = 20 mm we use Q245 - A, > 20 mm we use Q245 - B; According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection. |

|

Point 2-Dryer Drum WeldingThe dryer cylinder section for toroidal welding, longitudinal along the entire circumference of not more than two weld article number, and shell welds shall be full, the minimum is not lower than the parent metal surface, the top should not be higher than 3 mm, feed plate weld should be smooth.Weld edge bite depth should not be greater than 0.5 mm, continuous length should not be greater than 100 mm, should not exceed the total length of each weld bite edge which 10% of the weld length. |

|

|

|

|

Point 3-nspectionExamination all the parts according to the drawing after processing completion. Spraying primer, rust preventing paint, and heat resistance paint. |

Rotary Dryer Structure

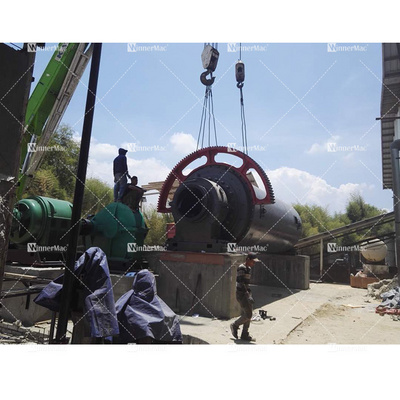

Working Site of Rotary Dryer

Technical Parameters

Certifications

Certifications

Packing & Delivery

Packing & Delivery

Hot Searches