NaN / 0

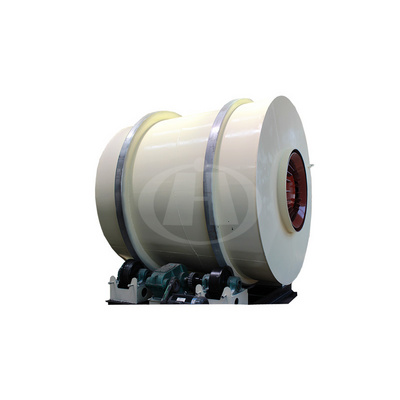

Factory Price Energy Saving Industrial Drying Equipment, Slurry Sludge Coal Sawdust Silica Sand Three Cylinder Drum Rotary Dryer

Get Latest Price

US$ 30000

≥1 Sets

Quick Details

Type:

Drum Drying Equipment

Place of Origin:

CHINA HENAN

Brand Name:

Baichy

Power:

30000

Product Details

Factory Price Energy Saving Industrial Drying Equipment, Slurry Sludge Coal Sawdust Silica Sand Three Cylinder Drum Rotary Dryer

Baichy three drum dryer three cylinder dryer for hot sale -- Introduction

Three-cylinder rotary dryer is mainly applied for stoving slag, sand, coal, fly ash, iron powder, ore, quartz sand, and other particle materials. It has the following characteristics:

1. The cylinder protects itself, and thermal efficiency can be up to 95%. The whole length of the dryer was reduced to 50% approximately than mono-cylinder and reduced land investment to 50% approximately

2. Cylinder adopts heat-resistant and wear-resistant steel plate welding with long service life and easy maintenance.High thermal efficiency, temperature of the outer cylinder is 60or below(temperature of outer mono-cylinder is high to 150°C)

3. Low temperature of outlet, long service of dust removal machine. It also can be directly connected to the air box pulse bag filter.

4. Without gear and pinion drive, but with wheel rotation applied, the level operation of the complete machine makes the system simple and reasonable.

5. Air heater could match a boiling furnace or an oil furnace can also be applied, which can dry materials with a size below 20mm.

6. Final moisture index can be adjusted according to the requirements of customers.

The Rotary Drier is widely used in the field of building materials, metallurgies, chemical industry, cement, and so on.

The Rotary Drier is widely used in the field of building materials, metallurgies, chemical industry, cement, and so on. It can dry slag, coal powder, mining powder, clay, sand, limestone, and so on. It is made of a rotary body, lifting blade, driving device, supporting device, etc. The dryer has the advantages of reasonable structure, high efficiency, low energy consumption, and convenient for transportation.

Working principle

1. The material first goes into the inside drum, because there are spiral shape boards fixed in the drum, when the dryer makes rotary working, the spiral shape board will stir the material and make the material do the movement.

2. When the material reaches the right side of the drum, it will go into the second drum for further drying.

3. The same working principle, the material then goes into the outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

| Model | Diameter of outer cylinder(m) | Length of outer cylinder (m) | Drum volume(m³) | Rotation speed(r/min) | Max. air flow temperature(℃) | Production capacity(t/h) | Power(kw) |

| 2.0*4m | 2 | 4 | 12.56 | 4-10 | 700-750 | 8-15 | 5.5x2 |

| 2.2*5m | 2.2 | 5 | 18.99 | 4-10 | 700-750 | 12-20 | 5.5x2 |

| 2.5*6m | 2.5 | 6 | 29.43 | 4-10 | 700-750 | 18-28 | 7.5x2 |

| 2.8*6m | 2.8 | 6 | 36.92 | 4-10 | 700-750 | 25-35 | 11x2 |

| 3.0*6m | 3 | 6 | 42.39 | 4-10 | 700-750 | 30-40 | 7.5x4 |

| 3.0*7m | 3 | 7 | 49.45 | 4-10 | 700-750 | 30-45 | 7.5x4 |

| 3.2*7m | 3.2 | 7 | 56.27 | 4-10 | 700-750 | 35-55 | 11x4 |

| 3.6*8m | 3.6 | 8 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5x4 |

| 4.0*10m | 4 | 10 | 125.60 | 4-10 | 700-750 | 70-100 | 22x4 |

20 national service mileage:

Service mileage for local customers to provide equipment installation, commissioning and after-sales service

Baichy headquarters is located in the industrial park in Jiaozuo City. It covers a total area of 200,000 square meters, including 150,000 square meters of standarized workshop. There are more than 200 sets of various large and medium-sized metal processing lathe, riveting machine, welding equipment and assembly equipment. We have more than 500 workers, including more than 20 middle and senior technicians. Baichy is mainly focus on 4 series products: stone crusher machines, sand making equipment, powder grinding mills, mineral processing equipment and their spare parts. Every year, Baichy can turn out 1,000 sets of crushers and 10,000 tons of crusher parts.

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Hot Searches