NaN / 0

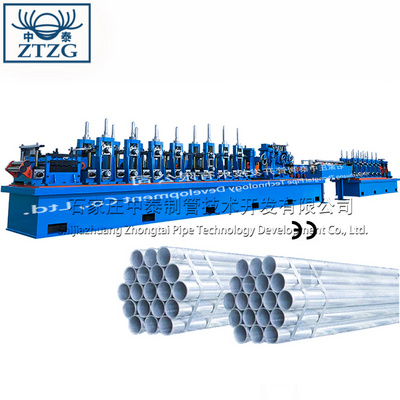

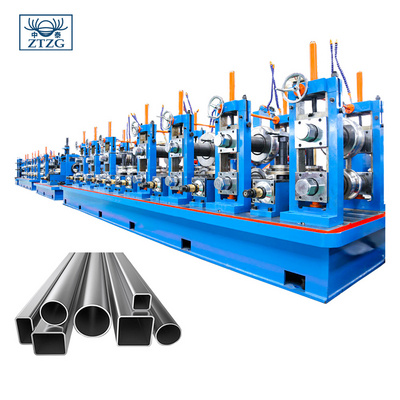

Energy Saving Carbon Steel ERW Tube Forming Mill Pipe Rolling Line Manufacturer

Get Latest Price

US$ 690000

≥1 Sets

US$ 680000

≥6 Sets

Quick Details

Pipe Material:

Carbon steel/stainless steel

Production Capacity:

30-100m/min

Place of Origin:

Hebei, China

Brand Name:

TENGTIAN

Product Details

Product Description

HG273

HG273 ERW Welded Pipe Mill Line

is designed to produce round pipe (Diaφ114-273mm, wall thickness 4.0-10.0mm).

TENGTIAN HG273 ERW Pipe Mill is a complete set of equipment for producing electric resistance welding (ERW) steel pipes. It consists of a shear and welder, welding speed up to 30-80m/min, packaged in wooden cases, pipe thickness ranging from 4.0-10mm and a hydraulic station to ensure its smooth operation. This ERW Tube Rolling System is an ideal ERW Tube Forming Equipment to produce superior quality electric resistance welding pipe production line. The high-quality welds in ERW pipes make them ideal for withstanding high pressure and harsh environmental conditions, ensuring the safe and efficient transportation of oil and gas.

Specification

|

item |

value |

|

Applicable Industries |

Hotels, Manufacturing Plant, Construction Works, Energy & Mining |

|

Showroom Location |

United States, Italy, Pakistan, India, Russia, Thailand, Tajikistan |

|

Video Outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

|

Warranty of Core Components |

1 Year |

|

Core Components |

Engine, Gearbox, Motor, Gear |

|

Condition |

New |

|

Type |

Pipe Production Line |

|

Pipe Material |

Carbon steel |

|

Application |

Energy Supply Pipe |

|

Production Capacity |

30-80m/min |

|

Place of Origin |

Hebei, China |

|

Brand Name |

Tengtian |

|

Voltage |

380V |

|

Power |

400KW |

|

Dimension(L*W*H) |

18m*160m*2m |

|

Weight |

25000kg |

|

Warranty |

1 Year |

|

Key Selling Points |

High-accuracy |

|

After-sales Service Provided |

Engineers |

|

Pipe Length |

6-12m |

|

Pipe Diameter |

114-373mm |

|

Pipe Thickness |

4.0-10.0mm |

|

Welding Method |

High Frequency Welding |

|

Material |

Carbon Steel, Stainless Steel, Alloy Steel |

|

Service Treatment |

Pickling, Passivation, Polishing, Anodizing, Plating, Coating |

| Forming Process | Roll Forming |

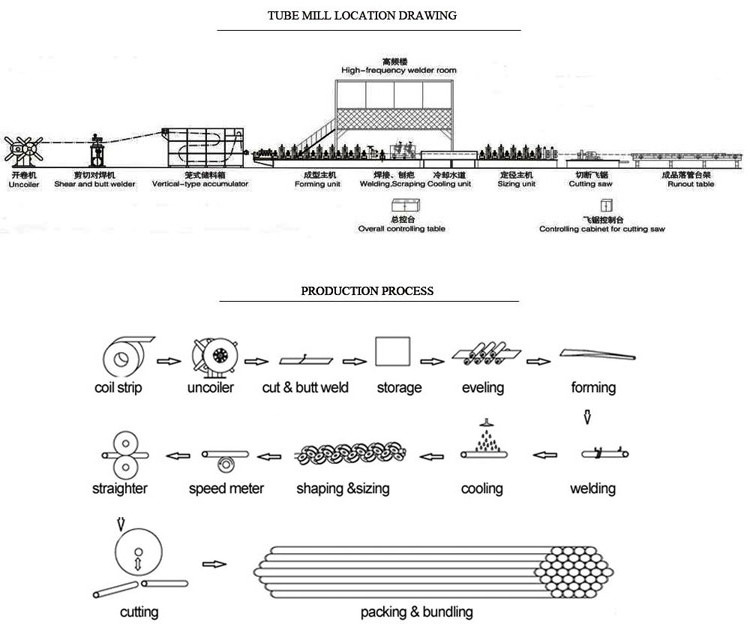

Production Process

Material (steel coil)→uncoiler→ pinching and leveling →shear and welder→horizontal (or cage) accumulator→forming mill→HF soild welder→ external burr removing → IF annealing → heat treatment → air cooling → water cooling →sizing mill→rounghly straightening (turkey head)→cut off machine→run out table

Hot Searches