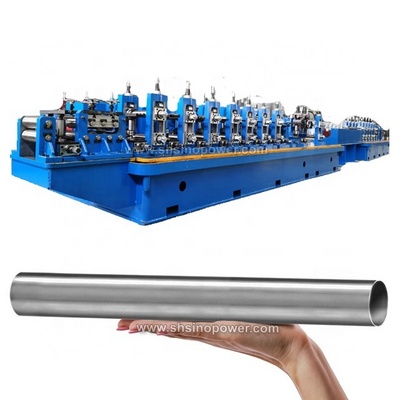

Machine model: HF32

Pipe Material:Carbon steel coil, galvanized steel coil, other hot or cold rolled steel coil.

Round Pipe diameter: Φ16mm—Φ50.8mm

Round Pipe thickness: 0.4mm—2.0mm

Square Pipe diameter: F10x10mm—F30x50mm

Square Pipe thickness: 0.4mm—1.5mm

Production speed: ≤120m/min