NaN / 0

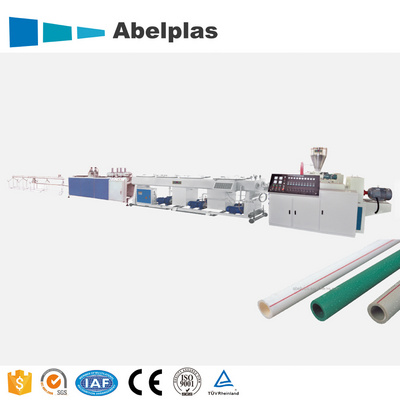

Factory Price PPR PP PE plastic tube extrusion line hot and cold water pipe making machine

Get Latest Price

US$ 23000

≥1 Sets

Quick Details

Screw Design:

Single-screw

Screw L/D Ratio:

33:1

Screw Speed (rpm):

1000 rpm

Place of Origin:

Shandong, China

Product Details

Product Description

Specification

PPR Pipe Production Machine

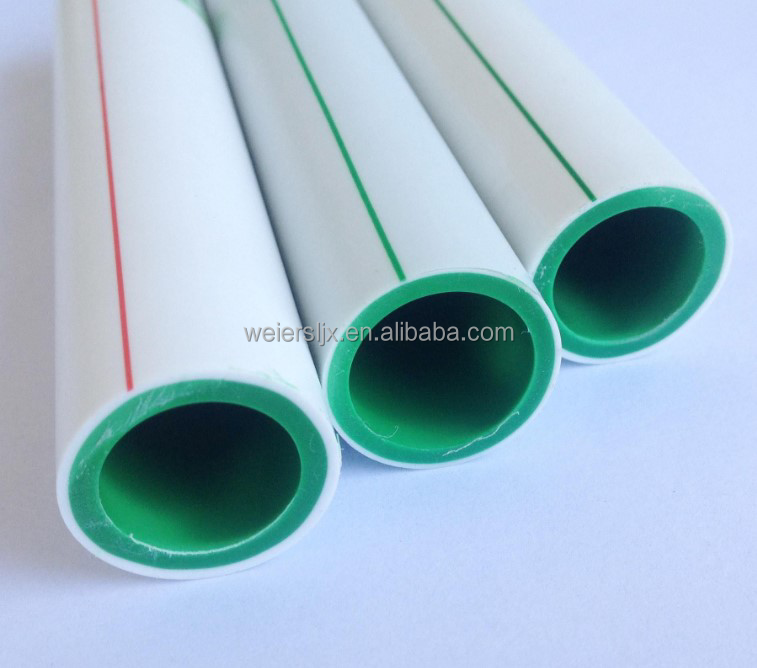

This production line is used for producing PP-R, PERT, Reinforced PP-R, and silicon core pipe. PP-R pipe has many advantages such as sanitation, heat-resisting, heat-reservation, simple line welding , reutilization for PERT, there is no need of cross linking techniques, but could be recycled, and with good heat-resisting stability.

|

Brand Name

|

Weier

|

|

Model number

|

SJ65/33

|

|

Suitble resin

|

PPR resin

|

|

Line speed

|

1-27m/min

|

|

Output

|

100-120Kg/h

|

|

Total power

|

60KW

|

|

Power supply

|

380V 3P 50Hz

|

|

Delivery detail

|

50 days

|

|

Center height

|

1000±50mm

|

|

After-sales service provided

|

Engineers available to service machinery overseas

|

|

1

|

Automatic feeding system

|

|

2

|

raw material drying system

|

|

3

|

SJ65/33 high efficiency single screw extruder

|

|

4

|

SJ25 single screw extruder ( for mark line)

|

|

5

|

mold(including mouth mold, mandril, sizing sleeve, heating circle)

|

|

6

|

Ppr pipe sizing sleeves ( 16-63mm)

|

|

7

|

Vacuum sizing tank

|

|

8

|

Sprinkling cooling water tank

|

|

9

|

Haul off machine

|

|

10

|

dustless high speed cutter

|

|

11

|

ppr pipe reversal stacker

|

|

12

|

Electrical control system

|

Details Images

Certification & Exhibition

Packing & Delivery

ISO certified PC plastic hollow sheet production line extruder packing method:

1. Cover the fuselage with waterproof film first, and then fix it on the wooden tray at the exit with bolts and wires.

2. The electronic control parts and spare parts are packed in wooden cases respectively.

The auxiliary equipment is also packed in wooden cases.

4. All wooden materials have been fumigated and certified, and are exported to all parts of the world safely.

Hot Searches