(1) Motor brand:

Siemens

(2) Inverter brand:

ABB/Delta

(3) Contactor brand:

Siemens

(4)Relay brand:

Omron

(5) Breaker brand:

Schneider

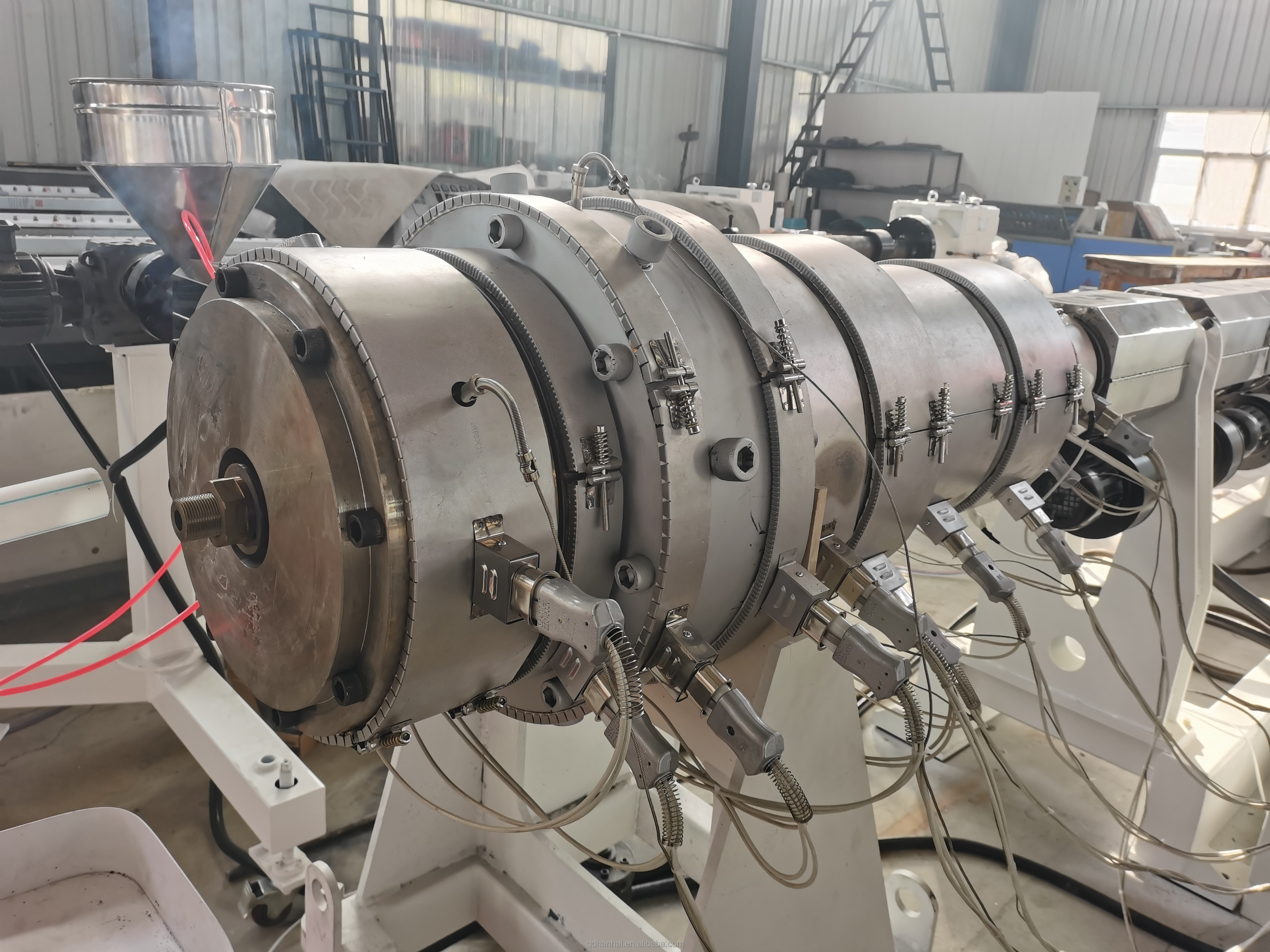

(6) Heating method: Ceramic or cast

aluminum heating

aluminum heating