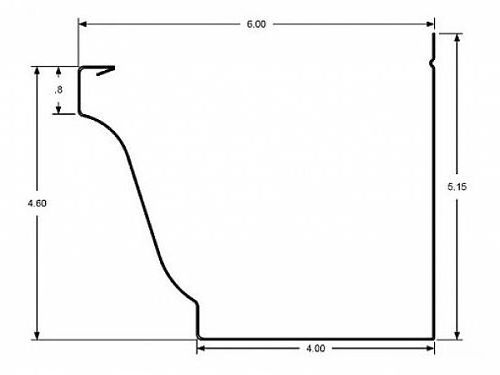

Main features of

Downpipe Roll Forming Machine

1.Material thickness:0.3-0.6mm

2.Forming speed: 5-12m/min (EXCLUDING CUTTING STOP TIME)

3.Forming roller: about 16 groups

4.Main motor power: 7.5KW

5.Hydraulic station power:4KW

6.Roller material: 45# forged steel, surface coated with chrome

7.Main shaft material: 45# steel,70mm

8.Hydraulic cutting pressure: 10-12Mpa

9.Cutting method: hydraulic powered, cutting after roll forming.

10.Cutting blade material: Cr12Mov quenching treatment

11.Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

12.Drive method:Chain drive, made in China

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will mpaint the coil on the roller and shaft, in case the roller and shast got corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts, and fix all the parts into container by the steel wire rope, and ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container

Sussman Machinery has exported its equipment and machines to more than 80 countries over the world, such as Russia, India, Australia, Malaysia, Nigeria, Romania, Rwanda,UNITED ARAB EMIRATES,Tanzania,Kenya,Philippines, Indonesia,South Africa,Mauritius,Mexico,etc. It has received excellent reputation. In the future, we are committed to better equipment and sales service and meeting customers’ requirements when and where they need.