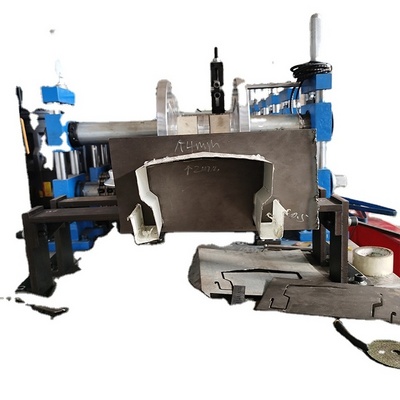

Capacity:3 tons

Coil inner diameter:450-550 mm

Feeding width: max 1000 mm

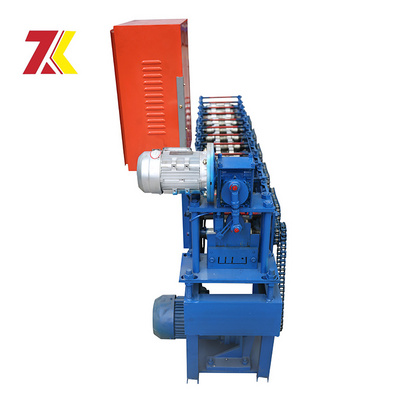

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine