Yixing City is the famous pottery capital in China. Most of Chinese ceramic industry is in Yixing.

Jiangsu Fist Special Ceramic Co., Ltd

is located in Yixing, established in 2016. We are also one of

Alibaba's

certified high-quality suppliers.

Superiorgeographical location and mature industrial chain of ceramic, we are a manufacturer specialized in developing, producing and selling ceramic materials and products which meet the market demand. We can provide professional

OEM & ODM

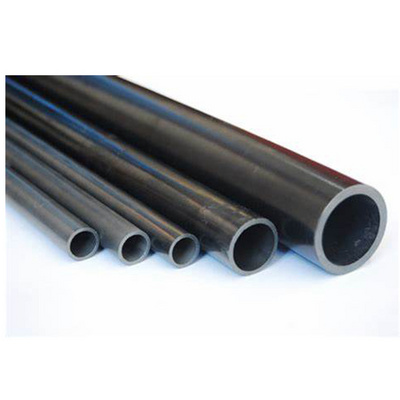

service. Our main products are alumina ceramic, zirconia ceramic, steatite ceramic, cordierite ceramic, mullite ceramic, electronic ceramic, industrial ceramic, daily ceramics, etc. With good quality, reasonable prices and stylish designs, our products are extensively used in machinery, textiles, electronics, automotive, plumbing, seal, humidification, new light source, household appliances, electric heating, solar power and other industries. Good quality and experience service win many customers including domestic and foreign. We

warmly welcome

new and old customers from all walks of life in the whole world to contact us for future business relationships to achieve mutual success!