NaN / 0

Hot selling reaction sintering refractory sic pipe silicon carbide roller SiSiC rollers

Get Latest Price

US$ 1

≥50 Pieces

Quick Details

SiO2 Content (%):

International Standard

Al2O3 Content (%):

none

MgO Content (%):

0.18%

CaO Content (%):

none

Product Details

Products Description

Silicon Carbide Nozzle is made of silicon carbide as the main raw material, adding a variety of chemical wear-resistant raw materials and anti-oxidant, effectively improving the wear resistance of the product, using SiO2 micro powder as the high-temperature bonding phase, a high-performance silicon carbide products by high-temperature firing.

Silicon Carbide Tube / Pipe / Beam Advantage

1. Dimensional stability at high temperature, anti-deformation, high high temperature strength

2. Thermal shock resistance, wear resistance and corrosion resistance

3. Anti-oxidation and erosion resistance

Can be widely used in: electric power, steel mill slag flushing groove, coal chemical industry, mining, transmission pipeline.

Product Application

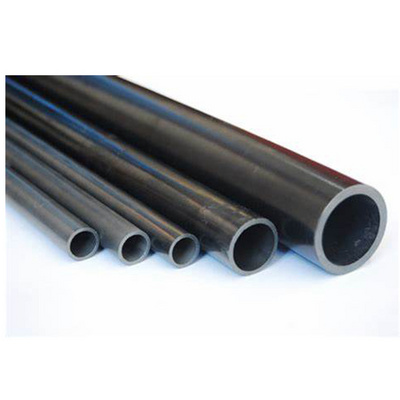

Silicon Carbide Tube / Pipe / Beam

Silicon carbide tubes are mainly used in medium frequency forging, various heat treatment electric furnaces, metallurgy, chemical industry, non-ferrous metal smelting and other industries. Widely used in metallurgical sintering furnace and intermediate frequency heating forging furnace. Length can be designed.

Specification

|

Technical Performance

|

Bulk Density

|

Abrasion Resistance

|

Moh's Hardness

|

CCS

|

|

|

g/cm³

|

%

|

MPa

|

Mpa

|

|

Silicon Carbide Tubes

|

2.7

|

1.66

|

>9.0

|

21.2

|

|

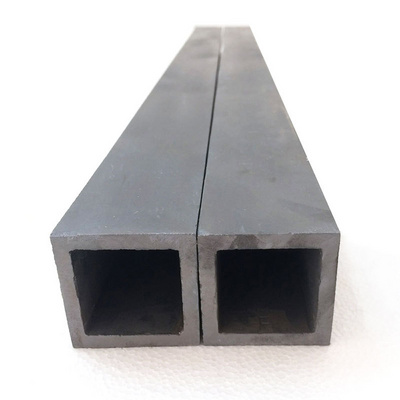

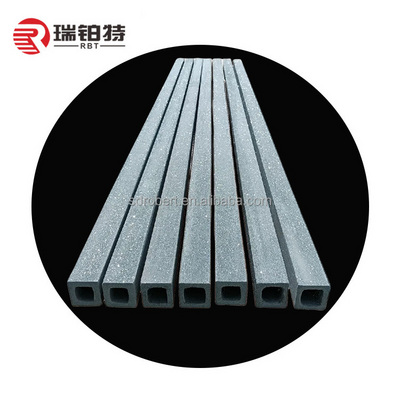

Shape

|

PIPE

|

|

Material

|

Silicon Carbide (SiC)

|

|

SiO2 Content (%)

|

International Standard

|

|

Al2O3 Content (%)

|

Customized

|

|

MgO Content (%)

|

0.18%

|

|

CaO Content (%)

|

Customized

|

|

Refractoriness (Degree)

|

Common (1580°< Refractoriness< 1770°)

|

|

CrO Content (%)

|

0.002%

|

|

SiC Content (%)

|

90-98%

|

|

Brand Name

|

RONGSHENG

|

|

Processing Service

|

Bending, Cutting, Moulding

|

|

Product name

|

silicon carbide kiln furniture

|

|

Density

|

3.02g/cm3

|

|

Characteristic

|

Long Service Life

|

|

Feature

|

High Temperature Resistance

|

|

Application

|

electric power, steel plant slag flushing trench

|

|

Sic Content

|

98% or Customized

|

|

Working Temperature

|

1800 Degree Celsius

|

|

Color

|

BLACK GREY

|

|

Certificate

|

CE,ISO9001

|

|

Raw material

|

Silicon Carbide (SiC)

|

Packing & Delivery

Certifications

All our products have been certified by the national quality management system

Hot Searches