NaN / 0

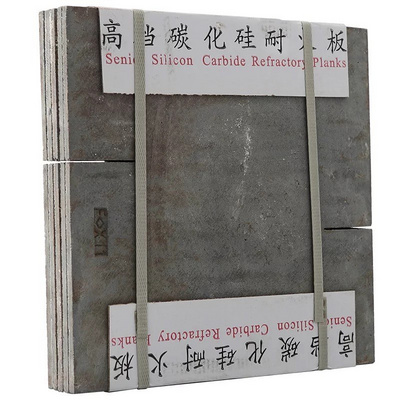

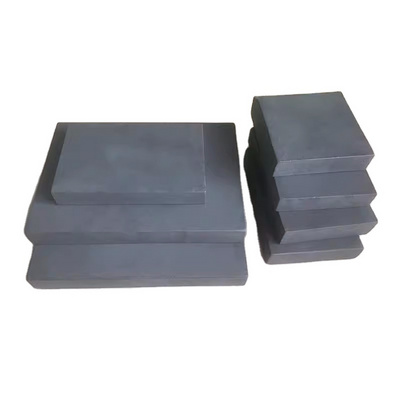

reaction sintering RB SiC silicon silicium carbide ceramic plate

Get Latest Price

US$ 3

≥1 Pieces

US$ 1

≥100 Pieces

US$ 0.5

≥1000 Pieces

US$ 0.1

≥10000 Pieces

Quick Details

Place of Origin:

Guangdong, China

Model Number:

SiC 006

Brand Name:

Hard

Material:

SiC

Product Details

reaction sintering RB SiC silicon silicium carbide ceramic plate

Reputation depends on quality, quality comes from Hard!

Product Description

SiC Ceramics :

SiC ceramics not only have excellent mechanical properties at room temperature, such as high flexural strength, excellent oxidation resistance, good corrosion resistance, high wear resistance and low friction coefficient, but also high temperature mechanical properties (strength, creep resistance). Etc.) is the best among known ceramic materials. Hot press sintering, pressureless sintering, hot isostatic pressing, the high temperature strength can be maintained up to 1600 ° C, which is the best material for high temperature strength in ceramic materials. Oxidation resistance is also the best of all non-oxide ceramics. Alias Emery.

Properties:

SiC ceramic has excellent mechanical properties, excellent oxidation resistance, high abrasion resistance and low friction coefficient. The disadvantage of SiC ceramics is that the fracture toughness is low, that is, the brittleness is large. For this reason, composite ceramics based on SiC ceramics, such as fiber (or whisker) reinforcement, heterogeneous particle dispersion strengthening, and gradient functional materials appear one after another. Improves the toughness and strength of the monomer material.

Data Sheet ↓

| Pressureless Sintering Silicon Carbide Ceramic Properties | ||

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | Grey Black | |

| Density | g/cm3 | 3.10-3.15 |

| Silicon Carbide Content | % | ≥99 |

| Porosity | % | <0.1 |

| Poisson's ratio | 0.16 | |

| Mechanical Properties | ||

| Hardness | HRA | ≥92 |

| Flexural Strength | Mpa | ≥400 |

| Compressive Strength(HV0.5) | Mpa | ≥2600 |

| Modulus of Elasticity | Mpa | 410 |

| Thermal Properties | ||

| Maximum Working Temperature | °C | 1600 |

|

Thermal Conductivity

(indoor temperature) |

W/m.K | 2.5 |

| Thermal Expansion Coefficient | 10-6/°C | 4 |

Application

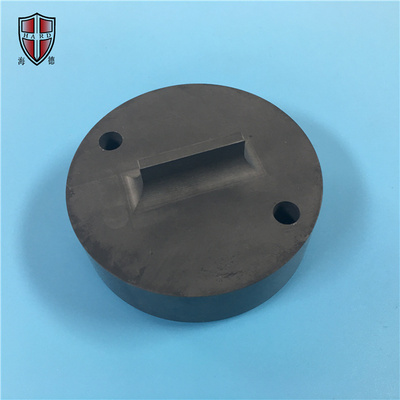

The original application of SiC is widely used in the machining industry due to its super-hardness properties, which can be used for grinding wheels, abrasive cloths, sandpaper and various abrasives. It was also discovered in the Second World War as a reducing agent and heating element in steel making, which promoted the rapid development of SiC. SiC ceramics have been widely used in petroleum, chemical, microelectronics, automotive, aerospace, aerospace, paper, laser, mining and atomic energy industries. Silicon carbide has been widely used in high temperature bearings, bulletproof plates, nozzles, high temperature corrosion resistant parts. And in the field of electronic equipment parts in the high temperature and high frequency range.

Hot Searches