NaN / 0

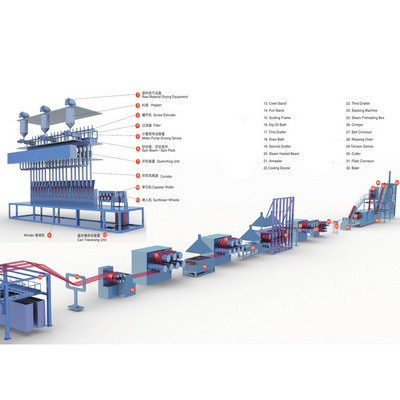

Fully Automatic Pet Water Bottles Recycle Polyester Staple Fiber Making Machine Plant

Get Latest Price

US$ 17000

≥1 Sets

Quick Details

Neck Diameter(mm):

28 mm mm

Max.Bottle Diameter(mm):

90 mm mm

Max.Bottle Height(mm):

300 mm mm

Bottle Volume(ml):

1500 ml

Product Details

Fully Automatic Small Plastic Blow Molding Water PET Bottle Blowing Machine Manufacturers

Product Description

# Main Technical Parameter #

|

Type

|

|

|

HQ- 2L - 2000

|

||

|

Container

|

Number Of Cavity

|

Cavities

|

2

|

||

|

|

Output

|

Pcs/Hr

|

1600-2000

|

||

|

|

Max Container Volume

|

L

|

2

|

||

|

|

Max Neck Diameter

|

mm

|

38

|

||

|

|

Max Container Diameter

|

mm

|

120

|

||

|

|

Mac Container Height

|

mm

|

300-330

|

||

|

Electrical

|

Number Of Lamp

|

pcs

|

32

|

||

|

|

Max Heating Power

|

kw

|

48

|

||

|

|

Actual Power Consumption

|

kw

|

24

|

||

|

Machine

|

Machine Dimension

|

m

|

2400*1600*1800

|

||

|

|

Machine Weight

|

T

|

2500

|

||

#

Application #

Suitable for 50ml-1l bottles

– Hot- filling bottles

– Mineral Water Bottles

– Carbonated Drinking Bottles

– Energy Drink Bottles

– Wine Bottles

– Milk Bottles

– Juice Bottles

– Oil Bottles ( with handle )

– Medical Bottles

– Cosmetic Bottles

– Jar ( Wide Mouth ) Bottles

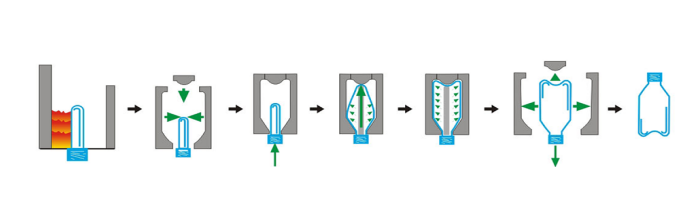

# Fully Automatic PET Bottle Blowing Machine #

HQ-L Fully automatic PET bottle blowing machine is the most stable two step blow down equipment of our factory, from one cavity to six cavity and can blow bottles of different capacity, from 0.1 L to 1 L, used for the production of PET/PP bottles of various shapes

# Advantages #

1. Stable performance

with advanced PLC.

2

. No contamination

and low noise with the air cylinder to drive the action instead of the oil

3 . Strong clamping force with high pressure and double crank links to lock the mold.

4 . Low cost , high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

# Servo Automatic Bottle Blowing Machine #

1. The automatic PET bottle blowing machine with safety ratio, no harm to the human, avoid the danger of taking out bottles by hand, reduce the loss of accident, improve the efficiency.

2. High speed high efficiency : the new model machine equals to 6 semi automatic.

3. Saving labor: The machine operate by one person or one person can operate two sets, saving 3~4 labors.

4. Stable performance: Adopts world famous brand PLC touch screen Human~Computer Interface, have the characteristics of accuracy, high speed, stable performance. The structure is simple, heater and main machine adopts slipway, convenient for maintenance.

5.The automatic blowing machine adopts double crank shaft, main connecting rod linkage with strong clamping force, have the function of mould close boost pressure when high pressure blowing bottles, the action stable and reliable.

# Semi Automatic PET Bottle Blowing Machine #

HONGQI semi-automatic blowing machine is an advanced 2-step PET blowing equipment. It is widey used for different shaped water bottles, CSD bottles and other beverage containers with PET, PP material. Infred self-rotary heater adopted. Mould closing is with double crank, to avoid mould expension (ensure half line very thin) under high pressure.

Machine is compatible, with approprite design, easy and safe to operate.

Auxiliary Machine

To operate the PET bottle blowing machine, you may also need some auxiliary machine. such as air compressor, air filter, air dryer, air tank and so on. this machine is needed to protect the machine from running smoothly and safe.

Sample And Mold

Our Molds adopt stainless steel materials and according to your demand to customized. if you do not have plan about bottle, we can also help you to design the bottle.

# We also provide the cap and preforms #

Related Machine

Hot Searches