NaN / 0

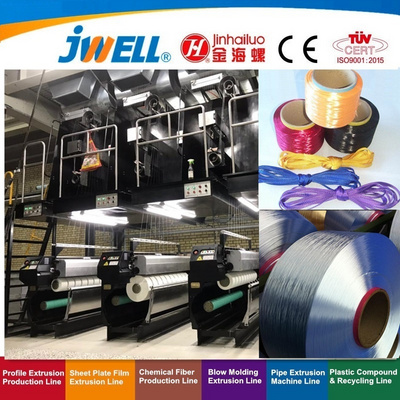

JWELL - POLYESTER PLASTIC STAPLE FIBER EXTRUDER MACHINE, HOLLOW PET STAPLE FIBER EXTRUSION LINE

Get Latest Price

US$ 200000

≥1 Sets

Quick Details

Screw Design:

Single-screw

Screw L/D Ratio:

34:1

Screw Speed (rpm):

666 rpm

Place of Origin:

Jiangsu, China

Product Details

FAQ

1. What are JWELL coming from?

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo after hundreds time of testing. Nowaday, in this location Zhoushan city, there are more than 300 companies in this reason. After more than 35 years development, JWELL is the TOP 1 extrusion machine supplier in China with 5 factories, 300 design&test engineer, 3000 employee located in Zhoushan, Shanghai, Taicang, Dongguan, Liyang.

2 . Why should I choose Jwell?

We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 500 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3000 staff Pioneer of Chinese extrusion machine supplier.

3. Are U the only JWELL in Alibaba?

Right! There are many many supplier with name Jwell in Alibaba, but I, Michael Chen, is the only approval sale manager working in Alibaba. Plz donot be cheated by other company in the name of JWELL screw, Jwell extruder, Jwell line, etc. They're all unhonest and untrustworthy supplier!

CONTACT JWELL, CONTACT MICHAEL CHEN, CONTACT SUCCESS!

JWELL- POLYESTER PLASTIC STAPLE FIBER EXTRUDER MACHINE, HOLLOW PET STAPLE FIBER EXTRUSION LINE

Application:

This machine is mainly used for spinning 30-330dtex polyester POY.

Main features:

Adopts LTM type pin screw, domestic-made continuous melt CPF, thus

extend the service life of spin packs.

Both top-mounted and bottom-mounted high-pressure rectangular and cup-shaped spin packs are available.

Unique planetary spinning pump and separately driving finish oil pump.

Evo and Cross Quench System with equably and stable flowing speed.

Individually controlled, imported inverter and components.

Application:

Suitable for CP spinning or Chips spinning to produce PET-FDY yarn.

Main features:

Uniform and stable quenching chamber system, to get good uster value.

Finishing spray system for denier filament and universal oil wheel feeding system.

Imported high precision inverter and imported high precision temperature controlling meter with setting, temperature controlling,

monitoring and recording functions.

Equipped with JW series precision winding and auto-doffing winder produced by Shanghai Jwell Chemical Fiber Machinery Co.,

Ltd, high succssfully of doffing, fineness of bobbin shape, and good function of unwinding.

Application:

This machine is mainly used for chips spinning of PA6 and PA66.

Main features:

Adopt new type of bimetal, barrel and special manifold design.

Energy saving spin beam, equipped with bottom mounted, high pressure cylinder spin pack.

Unique planetary spinning pump and separately driving finish oil pump. With well designed air suction device for mono-

mer.

Uniform front dismountable quenching chamber and unique nozzle type oil adding device.

Equipped with precision winding and high speed auto-doffing winders, high succssfully of doffing, fineless of bobbin shape,

and good function of unwinding.

100% PET Bottle Flakes for POY spinning production line.

Special designed screw and Pre-CPF, producing qualified POY filament yarn by 100% PET bottle flakes.

Brief introduction

This machine adopts the equipment manufactured by Jwell itself and the most advanced technology. It features the fol

lowing characteristics manufacturing spandex by means of melting method.

Adopting specialized spandex screw extruder and A.C inverter drive system.

Unique crossing additive adding system with the patent in China.

New type spin beam and high precision planetary pumps.

Novel, reliable, uniform and stable quenching chamber system.

Finish oil spraying and driving system which are suitable for spandex yarn.

Imported high precision inverter with imported high precision temperature controlling meter.

Specialized manual or fully automatic spandex winder. (equipped with JW3PA, JW3PB, JW470, JW460 and

JW690 etc.)

PA6+PET Composite Filament Spinning Machine

This machine is suitable for the production of polyester and polyamide type; co-spinning, center and split thin type; POY composite long

filament of orange petal type or specialized yarn type etc.

Adopting two groups of JWM series of screw extruders, with A.C inverter drive and LTM pin screw.

Two groups of melt distribution pipelines with static mixer can be connected with continuous CPF.

Separately temperature controlled spin beam of two cases with freezing valves, two groups of metering pump driving system and

precise planetary pumps.

Top-mounted or bottom-mounted composite spin packs and various composite spinneret.

Uniform and stable quenching chamber system.

Oil finish spray and driving system.

Two groups of uniform and reliable dowtherm heating system.

Imported high precision inverter and imported high precision temperature controlling meters with setting, temperature controlling,

monitoring and recording functions.

Adopting solid adhibiting and pressing melt yarn, various multilevel drawn industrial yarn manufactured

through high speed winding. Spinning denier range: 400-3000D 2 ends, 4 ends, 6 ends, 8 ends, 12 ends or 16 ends in each position 4 sets, 6 sets or 8 sets of hot godet for each position with compact configuration. Adopting domestic automatic winders

With excellent quality, large output, low cost and optimizing performance & price ratio

| Extruder size | Screw diameter(mm) | LD | PET Capacity(kg/h) | PA6 Capacity(kg/h) | screw RPM | driver power(kw) | Heat power(kw) | heat voltage(V) |

| JWM20 | 20 | 25 | 6 | 4 | 20-90 | 2.2 | 3 | 220 |

| JWM30 | 30 | 25 | 12 | 8 | 20-90 | 3 | 3 | 220 |

| JWM50 | 50 | 25 | 55 | 45 | 20-90 | 7.5 | 14 | 220 |

| JWM65 | 65 | 25 | 85 | 60 | 20-90 | 18.5 | 16 | 220 |

| JWM90 | 90 | 25 | 180 | 140 | 20-90 | 45 | 32 | 220 |

| JWM120 | 120 | 25 | 380 | 290 | 20-90 | 75 | 54 | 220 |

| JWM150 | 150 | 25 | 600 | 480 | 20-90 | 110 | 76.5 | 220 |

| JWM180 | 180 | 25 | 900 | 720 | 20-90 | 185 | 110 | 220 |

| JWM200 | 200 | 25 | 1050 | 800 | 20-90 | 220 | 150 | 220 |

All Key parts: screw&barrel,melt pump, mould , roller and downstream equipment are made by Jwell factory!

Assembly workshop

We only choose qualified supplier

Changzhou branch

Suzhou branch

Hot Searches