NaN / 0

waste pyrolysis oil engine oil recycling to diesel machine/used motor oil to diesel equipment

Get Latest Price

US$ 35000

≥1 Sets

Quick Details

Core Components:

reactor

Flow:

5-50 T/D

Place of Origin:

Henan, China

Brand Name:

huayin

Product Details

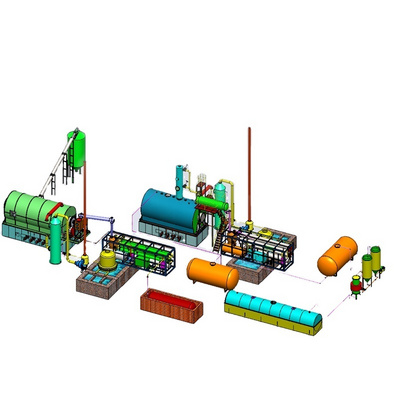

waste engine oil recycling to diesel machine/used motor oil to diesel equipment

Distillation is the chemical engineering processes and other facilities used in oil refineries to distills the incoming crude oil, pyrolysis oil and waste oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc.

Flow chart

Distillation plant works as follows:

1. Pump waste oil into distillation reactor by oil pump.

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

4 The last step , we need remove color and smell with special device.

Output diesel application

| Name | Usage |

| Fuel oil | Use for generator to make electricity |

| Waste gas | Recycled to furnace for heating reactor |

| Slag | Put it into the furnace for heating reactor |

Specification

| Item | Contents | |

| Raw material | Waste engine/motor oil Plastic pyrolysis oil Tire pyrolysis oil Lubrication oil | |

| Average out-put oil rate | 85%-90% | |

| End products | Diesel oil, waste gas, slag | |

| Structure form | Horizontal | |

| Operating pressure | Constant pressure | |

| Heating material | Coal, charcoal, fuel gas, fuel oil | |

| Model(Diameter*Length) (mm) | Reactor size | Capacity |

| D1500*L3000 | 3 Ton/Day | |

| D2000*5000 | 5 Ton/Day | |

| D2800*6000 | 10 Ton/Day | |

| Material of reactor | Q245R&Q345R boiler plate | |

| Thickness of reactor | 16mm, 18mm | |

| Mode of cooling | Circulating water cooling | |

| Space needed | Length: 30m, Width :10 m at most | |

| Power consumption | Average 15 KW/h | |

Cases show

Xinxiang Huayin Renewable Energy Equipment Co., Ltd is an enterprise with modern management , has been specializing in manufacturing waste management equipment for over 20 years. our equipment has been exported to over 66 countries including Romania, Hungary, Turkey, Slovakia,Ecuador, Guatemala, Haiti, Mexico, Peru,Canada , USA,Jordan, UAE, Lebanon, Kuwait , Italian , Chile , Poland , England , Thailand, Greece, Mexico , Benin , Indonesia , India , Singapore ,Russia etc.

Competitive Advantages

1. Reactor: Adopt automatic welding machine, X rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

2. Vacuum Degas & Dewater: Vacuum degassing and dehydration technology which can remove the harmful gas and free water in the waste oil to make sure it can be reused.

3. Waste Gas Treatment: The extra gas will be recycled to the furnace for second burning thus saving your heating fuel , and protect the environment.

4. Fully automatic Feeding System: The automatic feeding system can decrease the labor intensity.

5. Energy conservation: recycling of waste gas to heat reactor again can save energy and thereby reducing costs.

6. Security: our equipments have anti-blocking device and have pressure gauges, alarms and safety valves.

Packing and shipping

Totally need one piece of 40'FR and one piece of 40'HQ

Company information

Xinxiang Huayin Renewable Energy Equipment Co., Ltd is located in Xinxiang City, Henan Province, Our company is specialized in manufacturing waste tires/plastics to fuel oil pyrolysis machine and waste oil to diesel distillation machine since 1993.

We have obtained 11 patents and CE & ISO certificates related to our machine.

Our machine have been exported to more than 65 countries all over the world including Romania , Itaian , Chile , Poland , Hungary , USA, England , Thailand, Greece, Mexico , Benin , Indonesia ,Dubai , India etc.

30 experienced engineers for domestic and overseas after-sales service.

More than 2000 square meters running demo plant for customers’ visitation and learning.

The nearest airport is Zhengzhou Xinzheng International Airport. We will pick up you at the airport when you come to visit our factory. Welcome to visit us at any time!

Our service

1) Production with our automatic production line.

2) Quality Inspection;

3) Transportation to seaport and loading into containers:

4) Installation and Commissioning:

5) Worker training:

6) 12 months' Quality Warranty from the date of successful commissioning.

Hot Searches