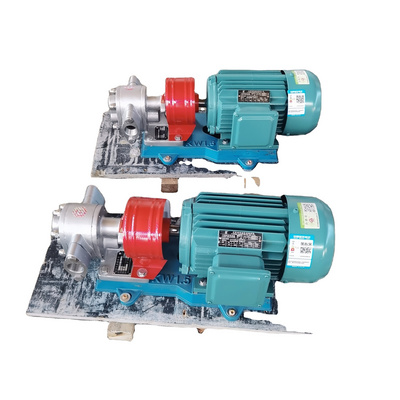

1. Mass production suitable for continuous production of industrialized assembly line

2. Small diameter range,and highly even

3. Time saving,highly efficient and energy saving

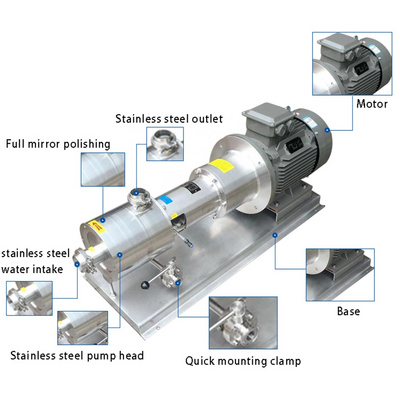

4. Low noise,stable operation

5. Reduced quality difference between lots

6. Material is fully dispersed snd sheared

7. Daliver in short distancc with low lift

8. Easy operation,convenient maintenance

9. Automatic control